PEMS plasma enhancing magnetron sputtering coating device

A magnetron sputtering coating and plasma technology, which is applied in the field of plasma-enhanced magnetron sputtering coating equipment, can solve the problem that the atomic or molecular ionization rate of the membrane material cannot meet the requirements of high-tech products, and achieve enhanced cleaning effect and attached Focus on improving the coating speed and enhancing the effect of ionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the given examples are not intended to limit the present invention.

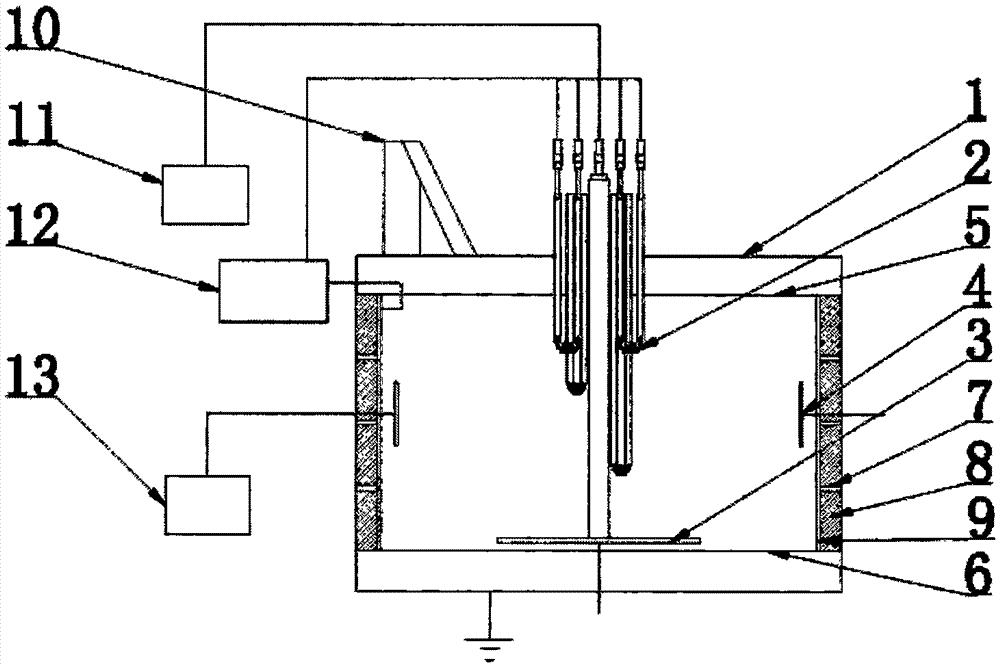

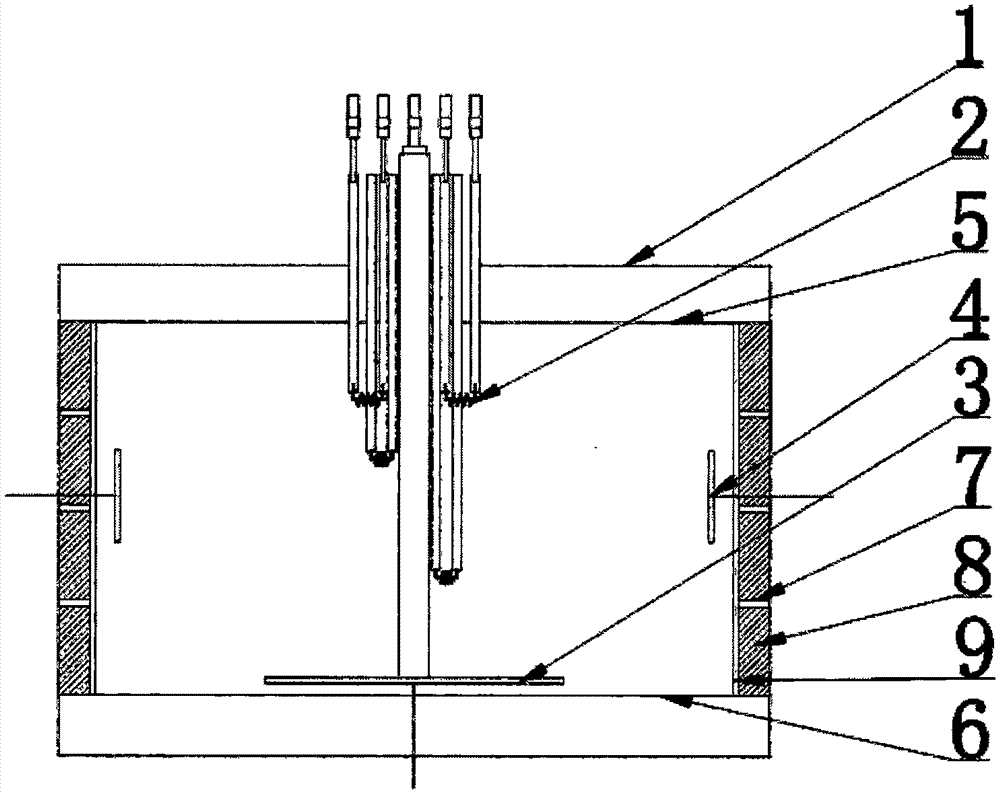

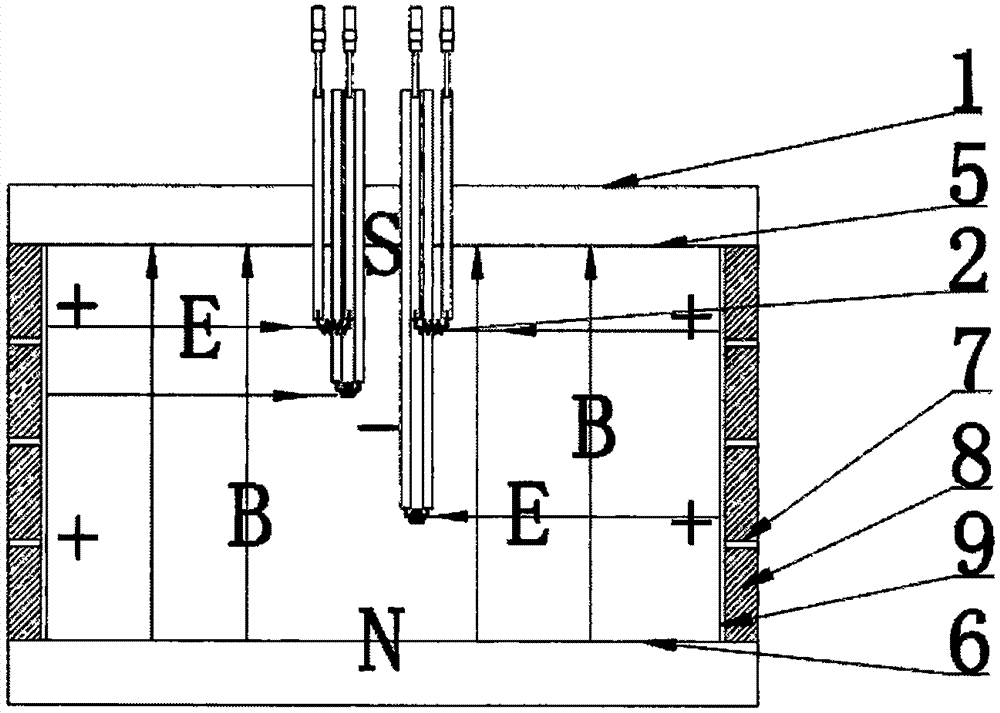

[0028] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention includes a vacuum chamber 1, an upper cover lifting mechanism 10 and a power supply, and the vacuum chamber 1 is provided with a cathode tungsten wire 2, a magnetic pole plate, a magnetron target 4 and a workpiece table 3, and the cathode tungsten wire 2 passes through the filament The fixed column is fixed at the top center of the vacuum chamber 1, and the cathode tungsten wires 2 are arranged in an orderly manner around the center of the vacuum chamber 1. The magnetic pole plates include an upper magnetic pole plate 5 and a lower magnetic pole plate 6, and the upper magnetic pole plate 5 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com