Wave-transmission and thermal-insulation material with high-temperature radiation resistance and preparation method of material

A heat-insulating material and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant radiation-transparent wave-transparent heat-insulation materials and their preparation, can solve problems such as uncontrollable, large differences in particle diameters of opacifying agents, and insufficient performance of high-temperature-resistant radiation-transparent wave-transparent heat insulation, etc. , to achieve the effect of good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

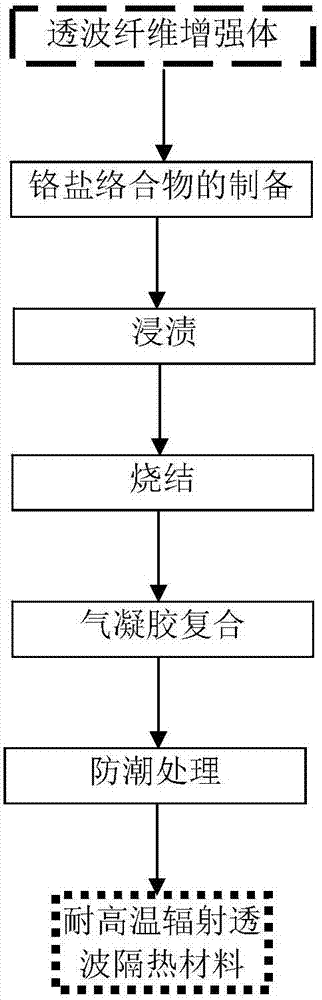

[0021] Specifically, the present invention provides a method for preparing a heat-resistant, radiation-resistant, wave-transparent and heat-insulating material, the method comprising the following steps:

[0022] (1) Preparation of chromium salt complex

[0023] In the present invention, chromium nitrate, chromium phosphate or chromium acetate are taken as examples, but not limited thereto, add water (such as pure water) or alcohol solution to dissolve and dilute, and then add a certain concentration of weakly alkaline solvent to control its pH The value is 7-8, fully stirred evenly to obtain a chromium salt complex solution; in the present invention, the dosage and concentration of the chromium salt complex are adjusted so that the mass ratio of chromium trioxide to wave-transparent fiber reinforcement is 1:0.05 ~0.15.

[0024] (2) Dipping

[0025] Use the chromium salt complex solution to impregnate wave-transparent fiber reinforcements; in the present invention, the glass...

Embodiment 1

[0040] Dissolve chromium nitrate in ethanol solvent at a ratio of 1:2, and then stir for about 20 minutes to dissolve completely, then slowly add ammonia solution with a concentration of 1M into the chromium nitrate solution, and slowly drop until the solution reaches The pH value is 8, continue to stir for 30 minutes to obtain a chromium salt complex solution, and then inject it with a density of 0.1g / cm 3 In the quartz fiber-reinforced matrix, put it into a 100°C oven to dry after the sol-gel, and then put it into a muffle furnace at 600°C for 2 hours, then put the fiber preform into the mold, and use vacuum Silica sol and prefabricated body are compounded by compression molding, and then aged at room temperature for 36 hours and high temperature aged at 90°C for 36 hours. After the aging is completed, the acetone solvent is replaced twice, and then supercritical carbon dioxide is dried, and then methyl trimethyl Oxysilane was subjected to vapor-phase hydrophobic and moistur...

Embodiment 2

[0042] Dissolve chromium acetate into the water solvent at a ratio of 1:3, and then stir for about 25 minutes to dissolve completely, then slowly add ammonia solution with a concentration of 1M into the chromium acetate solution, and slowly add it dropwise until the solution reaches The pH value is 8, continue to stir for 30 minutes to obtain a chromium salt complex solution, and then inject it with a density of 0.1g / cm 3 In the mullite fiber-reinforced matrix, put it into a 100°C oven for drying after the sol-gel, and then put it in a 600°C muffle furnace for 2 hours, and then put the fiber preform into the mold, Silica sol and prefabricated body are compounded by vacuum pressing molding, and then subjected to room temperature aging for 36 hours and high temperature aging at 90°C for 36 hours. Trimethoxysilane was subjected to gas-phase hydrophobic and moisture-proof treatment to obtain a thermal insulation sample. The density of the high temperature-resistant wave-transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com