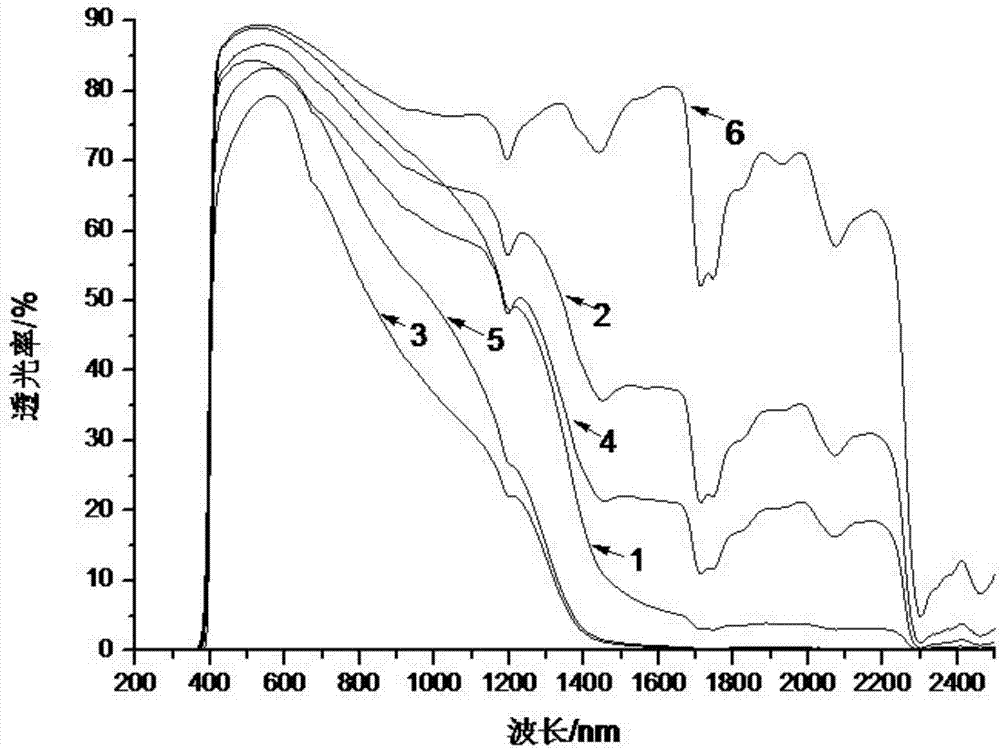

High-mid-infrared barrier and high-light transmittance PVB film and making method thereof

A technology with high light transmittance and high barrier, which is applied in the field of mid-infrared high barrier and high transmittance PVB film and its preparation, can solve the problems of high cost, low light transmittance and large haze of heat-insulating PVB film, and achieve Improved layering, superior mid-IR blocking and reflective capabilities, and production process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

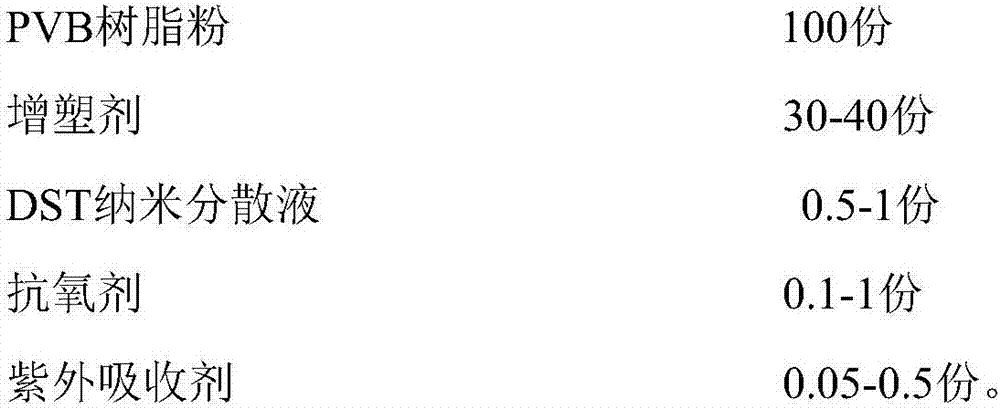

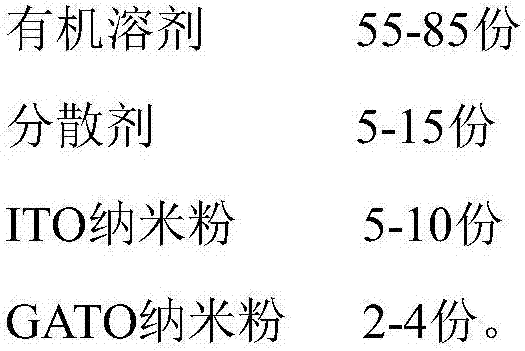

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of DST nano-dispersion liquid: After mixing 8.5kg of organic solvent triethylene glycol diisocaprylate, 0.8kg of nano-ITO powder and 0.2kg of nano-GATO powder, add 0.5kg of dispersant during slow grinding Silane coupling agent 6598, continue to grind on a ball mill for 24 hours to obtain a nano-DST dispersion.

[0040] (2) 100kgPVB resin powder, 0.5kg antioxidant mixture (from 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and 133.2g three [2, 4-di-tert-butylphenyl]phosphite), 0.1kg UV absorber mixture (composed of 50g 2-(2'-hydroxy-5'-tert-octyl)-benzotriazole and 50g2-(2'-hydroxy- 5'-methyl)-benzotriazole), added to the powder mixer, and stirred at a high speed of 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 50°C. Finally, 38 kg of plasticizer triethylene glycol diisocaprylate and 1 kg of nano-DST d...

Embodiment 2

[0042] (1) Preparation of DST nano-dispersion liquid: After mixing 8.5kg of organic solvent triethylene glycol diisocaprylate, 0.6kg of nano-ITO powder and 0.4kg of nano-GATO powder, add 0.5kg of dispersant during slow grinding Silane coupling agent 6598, continue to grind on a ball mill for 24 hours to obtain a nano-DST dispersion.

[0043] (2) 100kgPVB resin powder, 0.5kg antioxidant mixture (from 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and 133.2g three [2, 4-di-tert-butylphenyl]phosphite), 0.1kg UV absorber mixture (composed of 50g 2-(2'-hydroxy-5'-tert-octyl)-benzotriazole and 50g2-(2'-hydroxy- 5'-methyl)-benzotriazole), added to the powder mixer, and stirred at a high speed of 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 50°C. Finally, 38 kg of plasticizer triethylene glycol diisocaprylate and 1 kg of nano-DST d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com