Micro-carbon sphere oil base lubricating liquid and preparation method thereof

A lubricating fluid and micro-carbon technology, applied in the field of lubricating fluid, can solve the problems of low friction reducing performance of lubricating fluid, environmental pollution, etc., and achieve the effects of improving the friction reducing effect, being environmentally friendly, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

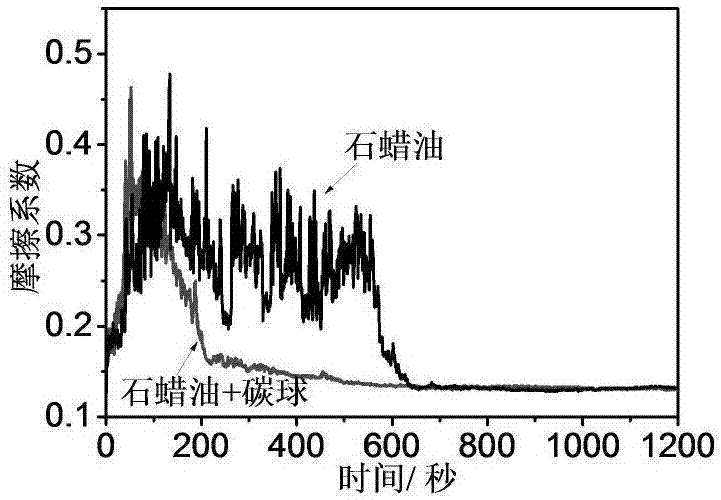

[0042] The microcarbon sphere oil-based lubricating fluid component is 0.5% microcarbon spheres accounting for the total mass of the lubricating fluid, and the balance is paraffin oil. The particle size of the microcarbon spheres is 450nm. Under the condition of a load of 10N, the research contains 0.5% microcarbon spheres The anti-friction performance of the lubricating fluid was tested under the same conditions using paraffin oil without microcarbon spheres as the lubricating fluid, and the test sample was made of stainless steel base material. attached figure 1 The change of the friction coefficient of the system before and after adding micro carbon spheres is given when paraffin oil is used as the lubricating medium. attached by figure 1 It can be seen that when lubricating with pure paraffin oil without carbon balls, there is a long running-in period in the early stage of the lubrication process, reaching about 600s. After the running-in period, the friction coefficient ...

Embodiment 2

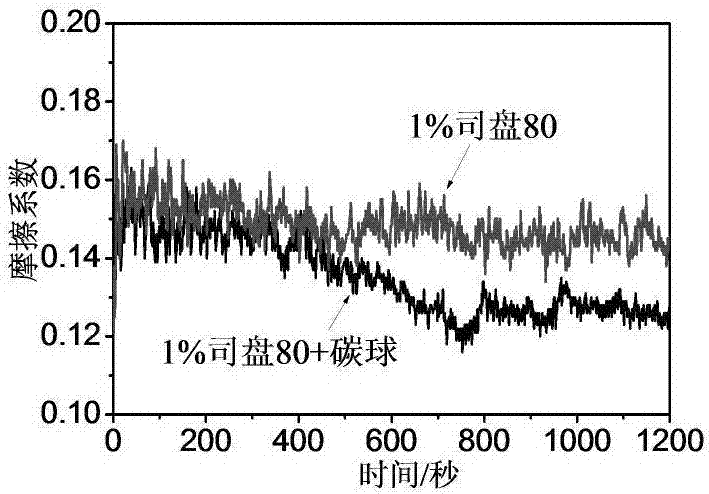

[0047] The components of the micro-carbon sphere oil-based lubricating fluid are micro-carbon spheres accounting for 0.5% of the total mass of the lubricating fluid, Span 80 accounting for 1% of the total mass of the lubricating fluid, and the balance being paraffin oil. The particle size of the micro-carbon spheres is 500nm. Under the condition of 10N, study the anti-friction performance of the lubricating fluid containing 0.5% carbon microspheres and 1% Span 80 in the total mass of the lubricating fluid, and use the lubricating fluid containing only 1.0% Span 80 without microcarbon spheres For comparative example, the test sample is a stainless steel base material. attached image 3 The friction coefficient of 0.5% micro carbon ball + 1% Span 80 + paraffin oil and 1% Span 80 + paraffin oil lubricating fluid changes with time, according to the attached image 3 It can be seen that the friction coefficient of the lubricating fluid after adding microcarbon spheres is relativel...

Embodiment 3

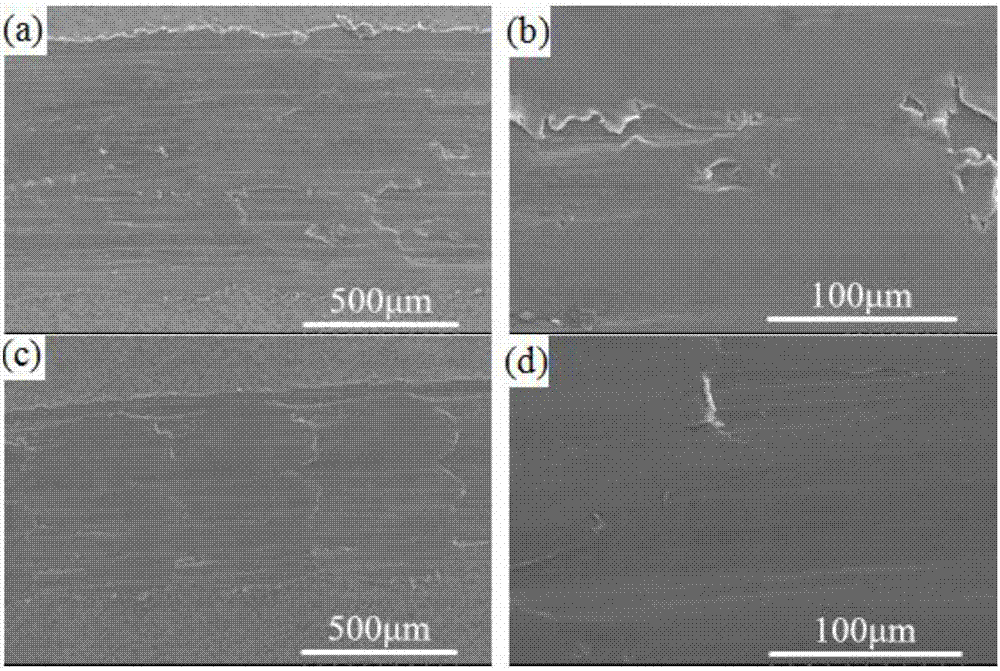

[0052] Micro-carbon sphere oil-based lubricating fluid: micro-carbon spheres accounting for 0.5% of the total mass of the lubricating fluid, Span 80 accounting for 5% of the total mass of the lubricating fluid, and the balance being paraffin oil. The micro-carbon spheres have a particle size of 450nm and a load of 10N Under the same conditions, the anti-friction performance of lubricating fluid containing 0.5% microcarbon spheres and 5% Span 80 was studied, and the lubricating fluid containing only 5.0% Span 80 without microcarbon spheres was used as a comparative example, and the test sample was stainless steel base material. Using scanning electron microscopy and two-dimensional profile measurement to characterize the wear marks on the substrate after the friction experiment, it was found that the lubricating fluid containing only 5.0% Span 80 and the lubricating fluid containing 0.5% microcarbon spheres and 5% Span 80 In contrast, the wear pattern of the substrate is not ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com