Preparation method of directional zeolite membrane

A zeolite membrane and directional technology, applied in metal material coating process, coating and other directions, can solve the problems of metal substrate corrosion, thickness increase, separation difficulty, etc., to achieve improved corrosion resistance, good corrosion resistance, increased Applied Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and easy to understand, preferred embodiments of the present invention are given below, and in conjunction with the accompanying drawings, are described in detail as follows:

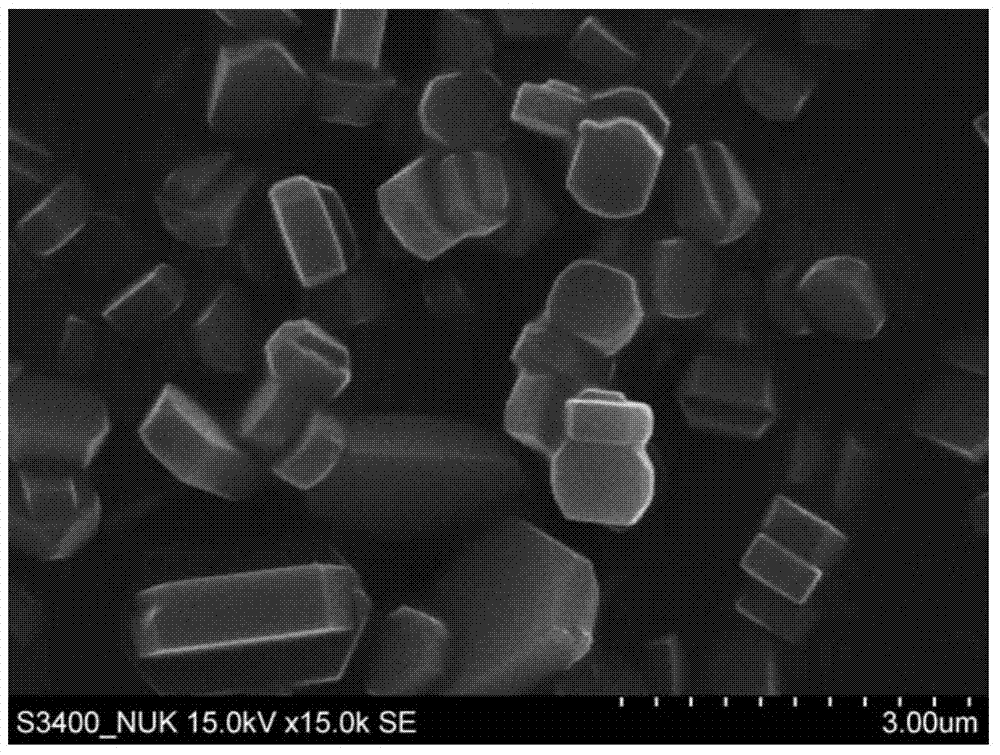

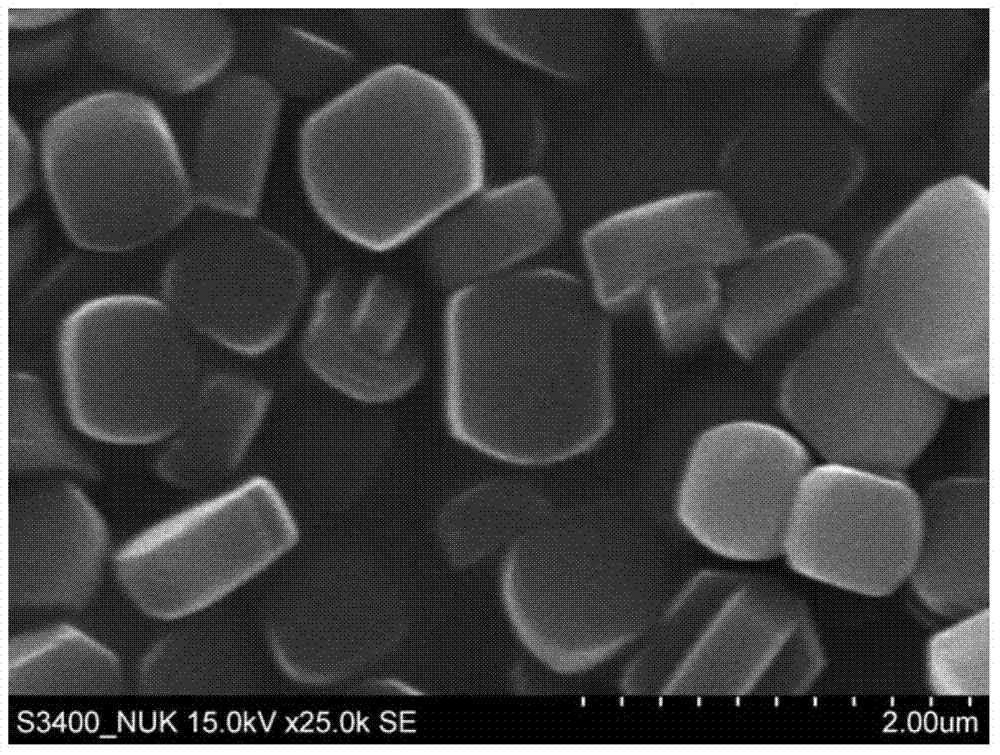

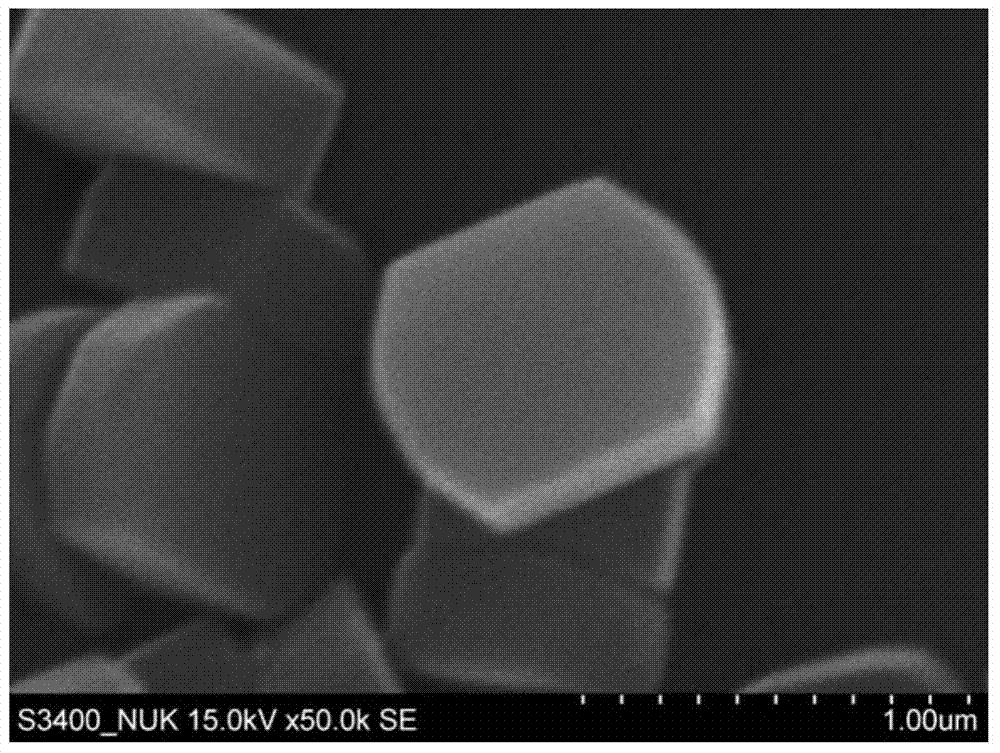

[0050] The present invention relates to a preparation method of a directional zeolite membrane, which is a dry glue type membrane preparation method, which comprises: providing a metal substrate; providing a zeolite crystal; and laying the zeolite crystal on the metal substrate to obtaining a first metal substrate; attaching a precursor liquid to the surface of the first metal substrate to obtain a second metal substrate, the precursor liquid contains a first structure directing agent; and the second metal The substrate and a predetermined amount of solvent are placed in an airtight container, and they are continuously heated to 100-550° C. to react for at least 15 minutes.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com