Dowel bar positioning support of cement concrete road surface based on composite

A technology of cement concrete and composite materials, applied to roads, roads, pavement details, etc., can solve problems such as positioning deviation, increased repair and maintenance costs, corrosion, etc., and achieve the goal of reducing workload, reducing premature failure, and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below with reference to the accompanying drawings.

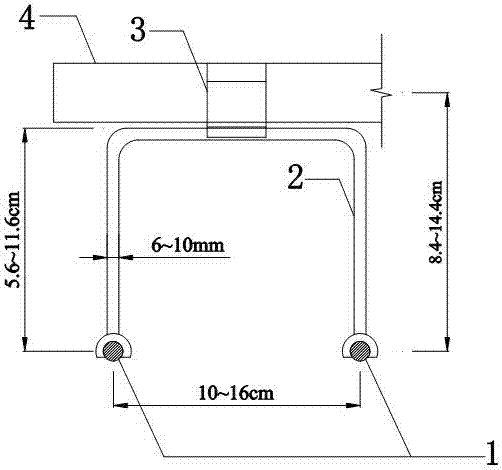

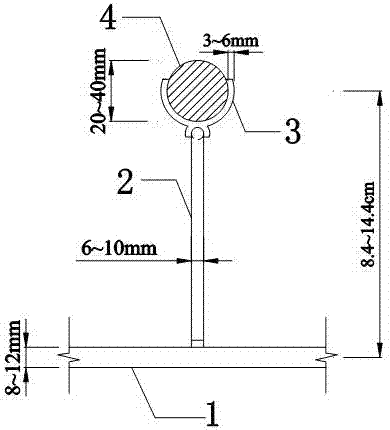

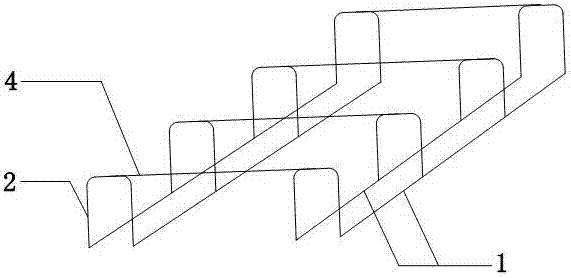

[0027] Such as Figure 1 to Figure 3 As shown, a composite material-based dowel bar positioning bracket for cement concrete pavement includes: two sets of dowel bar brackets arranged in parallel, each set of brackets includes two parallel positioning main rods 1, along the positioning main rod 1 A number of gate-shaped support legs 2 evenly connected between the two positioning main poles 1 in parallel in the length direction. The shape of the support legs 2 is approximately rectangular, and is used to accurately locate the position of the force transfer pole 4 on the hydraulic concrete road surface And a stable supporting force transmission rod 4; the base of the bracket leg 2 is provided with a circular hook claw portion, and the top cross bar of the bracket leg 2 is centrally provided with a detachable composite circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com