Digital signal processor

A digital signal and signal processing circuit technology, applied in the direction of coupling devices, stacked and separated printed circuit boards, and structural parts of electrical equipment, can solve the problems of unfavorable equipment miniaturization, complicated circuits, and difficulty in realization, and achieve compact structure , reduce the size of the equipment, the effect of short connection path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

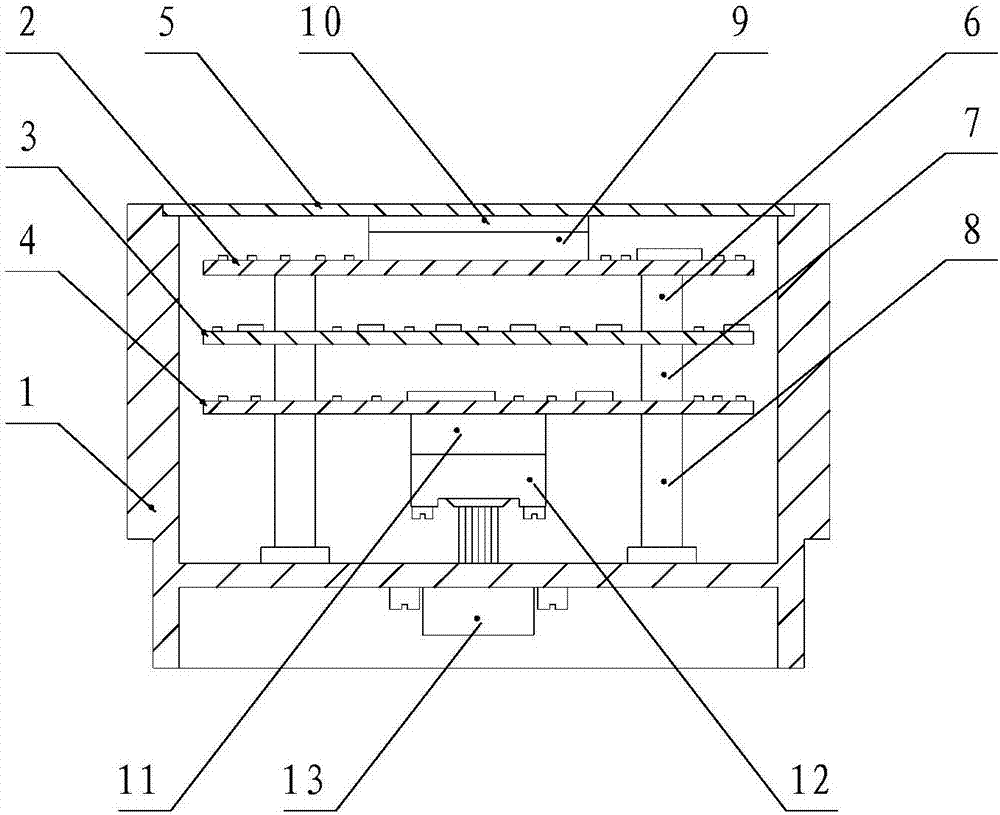

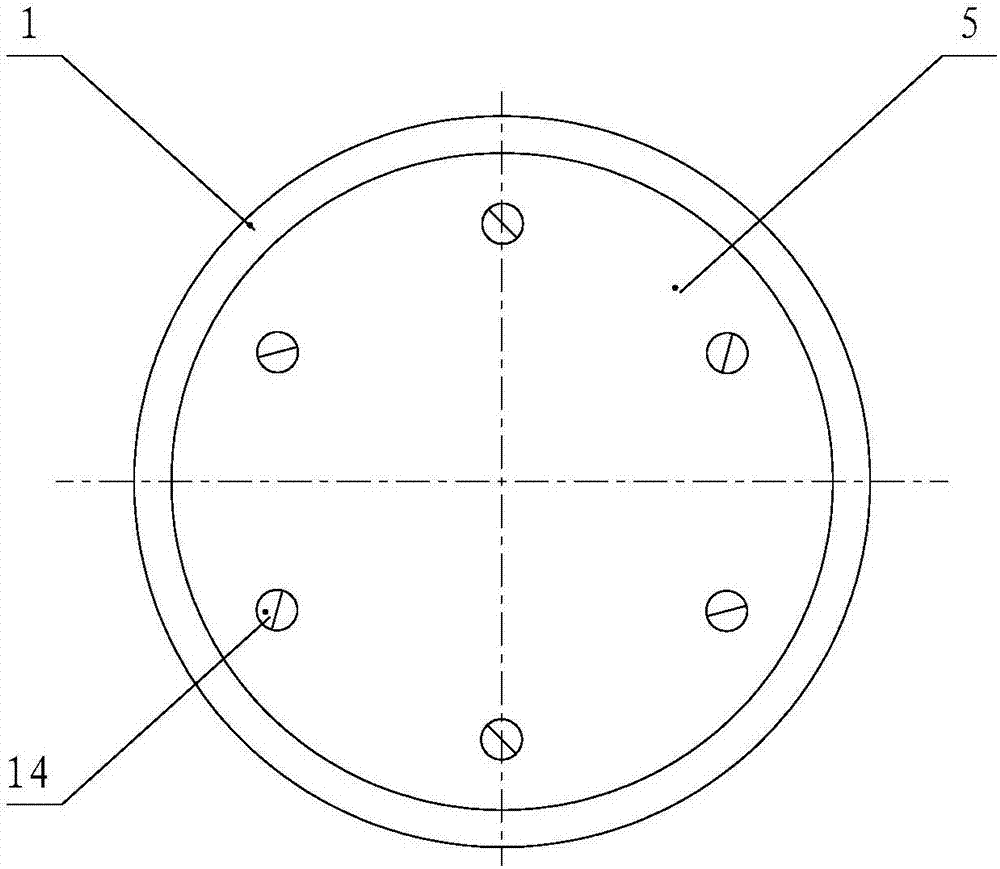

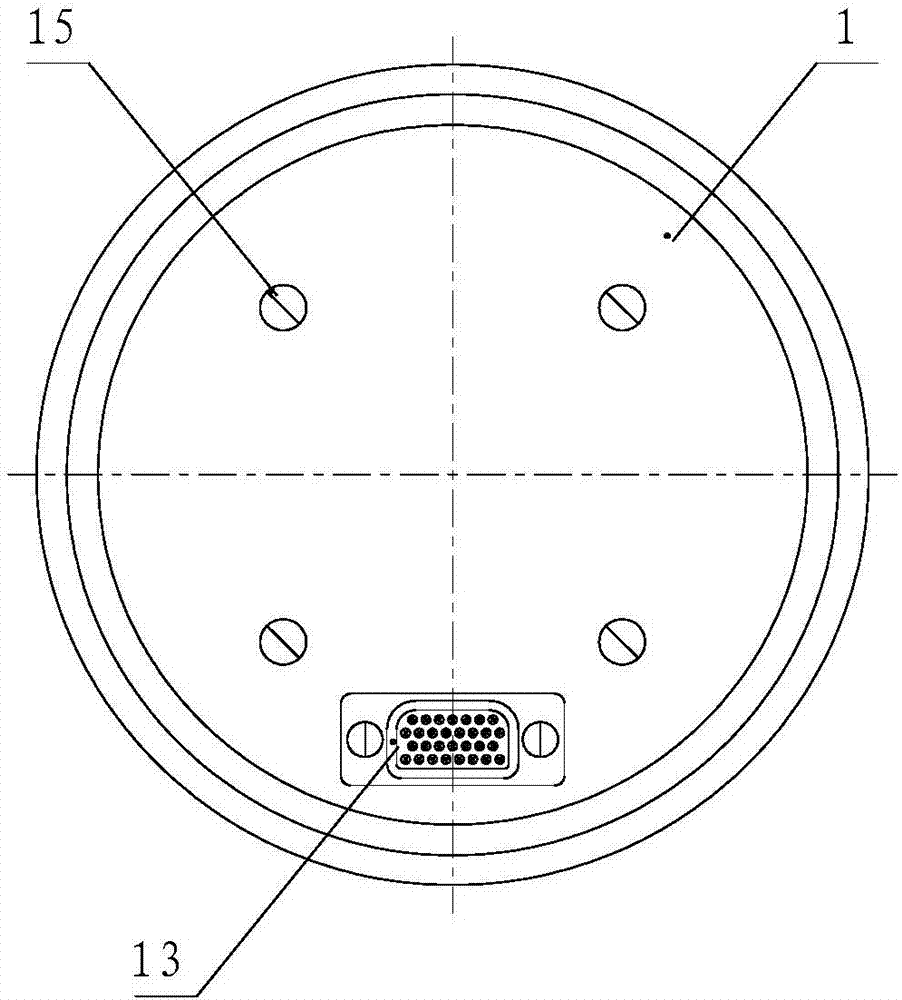

[0021] Such as Figure 1 to Figure 3 A digital signal processor shown includes a housing 1, a cover plate 5, a printed board assembly, and a low-frequency cable; the printed board assembly consists of a signal processing circuit board 2, a power supply circuit board 3, an interface circuit board 4, an upper Stud 6, middle stud 7, pillar stud 8; signal processing circuit board 2, power supply circuit board 3, interface circuit board 4 are placed sequentially from top to bottom in a stacked manner; 12 and a cable, the micro plug 12 is installed in the upper cavity of the housing 1, the socket 13 is installed in the lower cavity of the housing 1 and the socket 13 is electrically connected with the micro plug 12, the micro plug 12 is connected with the micro socket 11 at the bottom of the interface circuit board 4 connection to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com