Method for preparing garlic oil microcapsule powder

A technology of garlic oil and microcapsules, which is applied in the field of preparation of garlic oil microcapsule powder, can solve the problems of complicated process and high cost of freeze-drying, and achieve the effects of simple process, ideal dissolution rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific examples, the specific technical scheme of the preparation method of the garlic oil microcapsule powder of the present invention is further described. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the embodiments of the present invention.

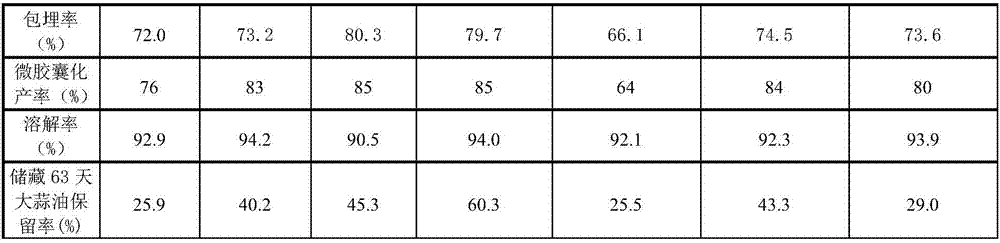

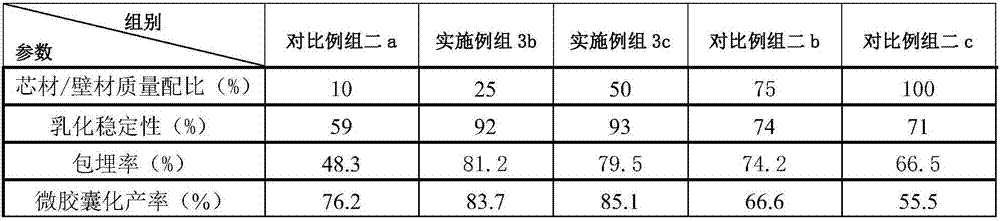

[0023] One. The method for preparing garlic oil microcapsules with regenerated silk fibroin and gelatin as wall material. Example Group 1:

[0024] 1. Main process: the garlic oil, microcapsule wall material, emulsifier and other raw materials are first prepared by emulsion, and then spray-dried to obtain powdered garlic oil with microcapsule structure; among them, the microcapsule wall material used is It is obtained by mixing regenerated silk fibroin with a molecular weight of 35-245KDa and gelatin with a Bloom value of 150-190g at a mass ratio of 6:4-4:6; the emulsifier used is a compound emulsifier. It is obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com