Garlic clove extrusion, peeling and peel twisting peeling machine

A technology of peeling machine and garlic, applied in the fields of application, food processing, food science, etc., can solve the problem of easily damaged garlic, achieve high peeling rate, convenient collection, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

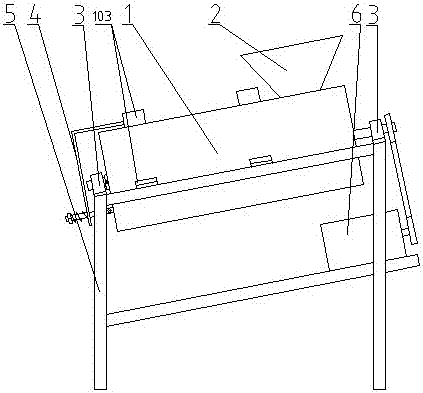

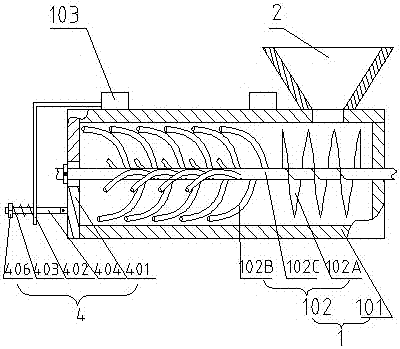

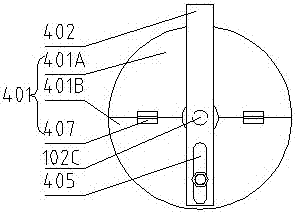

[0023] Such as Figure 1~3 , the described a kind of garlic extruding and rubbing peeling machine, its technical scheme is: comprise the peeling mechanism 1 that is used for peeling garlic, described peeling mechanism 1 comprises the peeling cylinder 101 that inner wall has protrusion and setting The peeling assembly 102 inside the peeling cylinder 101; the peeling cylinder 101 is arranged on the frame 5 and one end of the peeling cylinder 101 is provided with a feed hopper 2 for feeding; the other end of the peeling cylinder 101 is provided with a The discharge mechanism 4; the peeling assembly 102 includes a rotating shaft 102C that is coaxially arranged with the peeling cylinder 101 and penetrates the peeling cylinder 101 and is rotatably arranged on the frame 5 at both ends, and a rotating shaft 102C near the side of the feeding hopper 2 The screw feeding blade 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com