Stable ornidazole and S-ornidazole injections and a preparing method thereof

A technology of ornidazole injection and ornidazole, applied in the field of medicine, can solve problems such as product stability, compatibility and safety, rise of related substances in injections, non-compliance with prescriptions and process development evaluation, etc. , to achieve the effect of good compatibility stability and overcoming compatibility taboos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

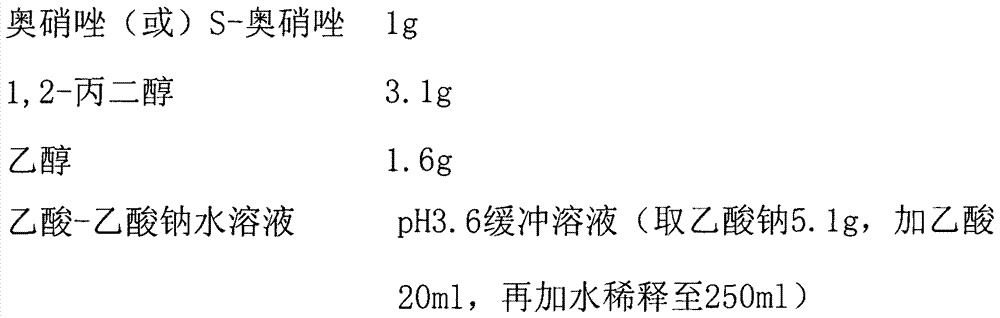

Embodiment 1

[0039]

[0040]

[0041] Preparation:

[0042] (1) 1,2-propanediol and ethanol are placed in a container and fully mixed;

[0043] (2) Add ornidazole (or) S-ornidazole, heat and stir at 40-45°C to dissolve;

[0044] (3) Add acetic acid-sodium acetate buffer solution to adjust the pH value to 5.6;

[0045] (3) Add medicinal charcoal (about 0.1% by weight), heat and stir at 40°C for 30 minutes, filter and decarbonize;

[0046] (4) finely filtering the filtrate of step (3) through a 0.45 μm microporous membrane to obtain an intermediate solution;

[0047] (5) The intermediate solution is measured, filled into ampoules after being qualified, filled with nitrogen, sealed, and leak detected;

[0048] (6) Sterilize by autoclaving at 121°C for 30 minutes, let cool, inspect with lights, and pack.

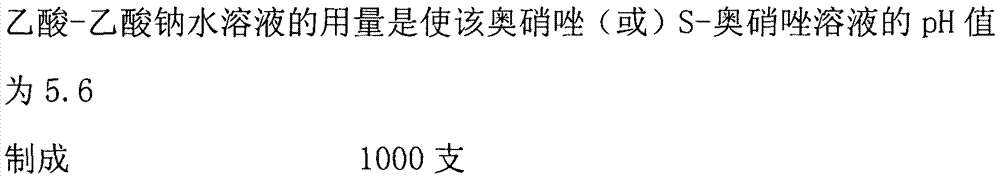

Embodiment 2

[0050]

[0051] Preparation:

[0052] (1) 1,2-propanediol and ethanol are placed in a container and fully mixed;

[0053] (2) Add ornidazole (or) S-ornidazole, heat and stir at 35-40°C to dissolve;

[0054] (3) adding acetic acid-sodium acetate aqueous solution to adjust the pH value to 5.8;

[0055] (3) Add medicinal charcoal (about 0.1% by weight), heat and stir at 40°C for 15 minutes, filter and decarbonize;

[0056] (4) finely filtering the filtrate of step (3) through a 0.45 μm microporous membrane to obtain an intermediate solution;

[0057] (5) The intermediate solution is measured, filled into ampoules after being qualified, filled with nitrogen, sealed, and leak detected;

[0058] (6) Sterilize by autoclaving at 121°C for 15 minutes, let cool, inspect with lights, and pack.

Embodiment 3

[0060]

[0061] Preparation:

[0062] (1) 1,2-propanediol and ethanol are placed in a container and fully mixed;

[0063] (2) Add ornidazole (or) S-ornidazole, heat and stir at 40-45°C to dissolve;

[0064] (3) acetic acid-sodium acetate aqueous solution, adjust the pH value;

[0065] (3) Add medicinal charcoal (about 0.1% by weight), heat and stir at 45°C for 15 minutes, filter and decarbonize;

[0066] (4) finely filtering the filtrate of step (3) through a 0.45 μm microporous membrane to obtain an intermediate solution;

[0067] (5) The intermediate solution is measured, filled into ampoules after being qualified, filled with nitrogen, sealed, and leak detected;

[0068] (6) Sterilize by autoclaving at 121°C for 30 minutes, let cool, inspect with lights, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com