A method of producing bimetallic composite pipe by traction method

A bimetallic composite pipe and base pipe technology, applied in metal extrusion dies, pipes, rigid pipes, etc., can solve the problems of shortened service life, loss of production enterprises, and increased workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

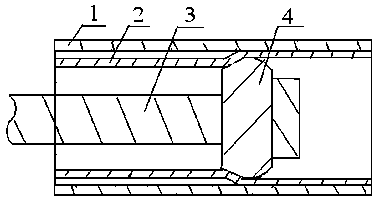

[0017] 1. Select a 6.1m-long 77mm×2.4mm seamless stainless steel pipe as the inner lining pipe, and then select a 6m-long 89.5mm×5mm carbon steel pipe as the outer base pipe. The half-cone angle of the cemented carbide tapered extrusion die is 10°, and the cemented carbide tapered extrusion die ( figure 2 ) with a maximum outer diameter of 75.30mm for the test.

[0018] 2. Cut the end of the lined stainless steel tube into 12 evenly distributed shapes with a cutting depth of 70~90mm, and then turn it out and fix it on the outside of the outer tube to realize the fixation between the inner liner and the outer base tube . Then apply mechanical oil and 2000 mesh graphite powder evenly in the inner liner as lubricant.

[0019] 3. Put the pipe section to be processed prepared in process 2 on the workbench and fix it to ensure that the center of the lined pipe is level with the drawbar.

[0020] 4. Press figure 1 Traction is performed in the manner shown in to achieve compoundi...

Embodiment 2

[0024] A 6.1m-long 44mm×1.8mm seamless stainless steel pipe is selected as the inner lining pipe, and a 6m-long 51mm×3mm carbon steel pipe is selected as the outer base pipe. The semi-cone angle of the cemented carbide tapered extrusion die is 10°, and the maximum outer diameter of the cemented carbide tapered extrusion die is 41.9mm for testing. The remaining steps are carried out with reference to the procedure in Example 1. The test results show that the bonding strength of the prepared pipe is 0.55MPa.

Embodiment 3

[0026] A 6.1m long 130mm×3.0mm seamless stainless steel pipe is selected as the inner lining pipe, and a 6m long 149mm×8mm carbon steel pipe is selected as the outer base pipe. The semi-cone angle of the cemented carbide tapered extrusion die is 10°, and the maximum outer diameter of the cemented carbide tapered extrusion die is 127.40mm for testing. The remaining steps are carried out with reference to the procedure in Example 1. The test results show that the bonding strength of the prepared pipe is 0.54MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com