Wooden craft product grinding and polishing machine

A polishing machine and handicraft technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machine parts, etc., can solve the problems of low processing quality, poor grinding uniformity, low grinding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

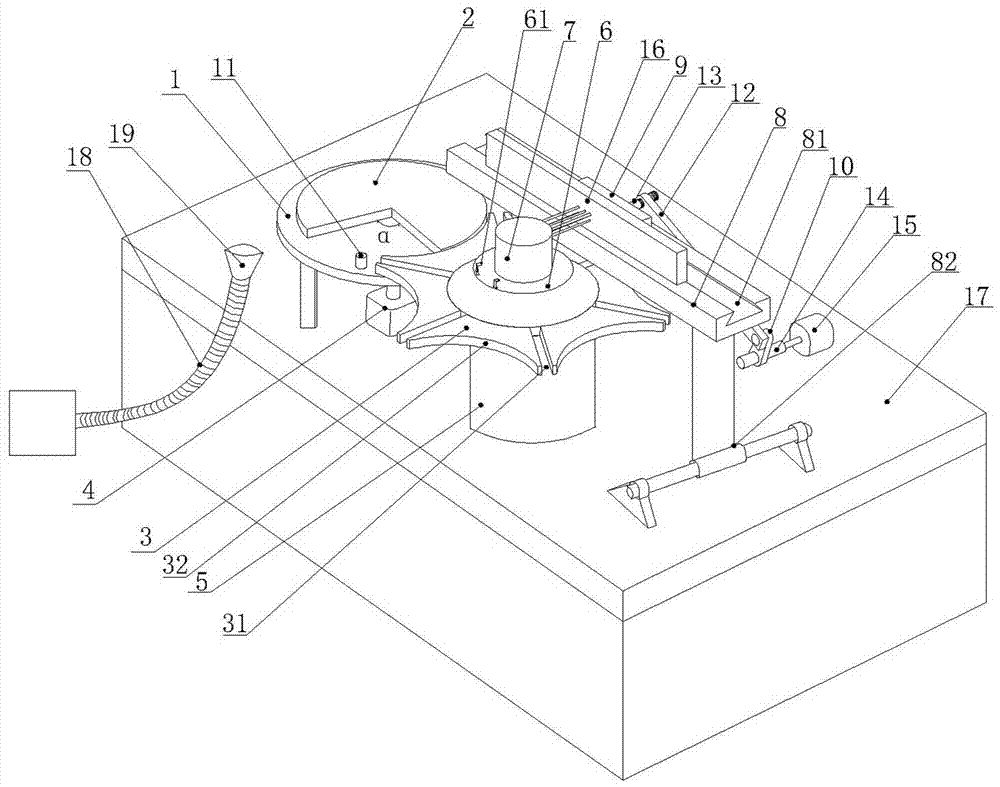

[0016] In order to enable those skilled in the art to better understand, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] like figure 1 The wooden handicraft polishing machine shown includes a power system, a sheave mechanism, a crank and rocker mechanism and a polishing brush body. The crank and rocker mechanism is located on the right side of the sheave mechanism, and the sheave mechanism includes a chassis 1. The driving dial 2 and the sheave 3 located above the chassis 1. The driving dial 2 is a convex locking arc with an arc length of 300°. The remaining 60° half of the convex locking arc is removed from the driving dial 2. The arc position α is provided with a cylindrical pin 11 fixed on the chassis 1, the center of the chassis 1 is fixed with a sheave mechanism motor 4 placed below the chassis 1, and the sheave 3 is fixed on the base 5 below through a rotating shaft. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap