Iron-nickel binary oxide-foam nickel composite electrode material and preparation method thereof

A binary oxide, composite electrode technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of limited application in a wide range, not very ideal, low conductivity, etc., and achieve excellent electrochemical performance. , the narrow band gap, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

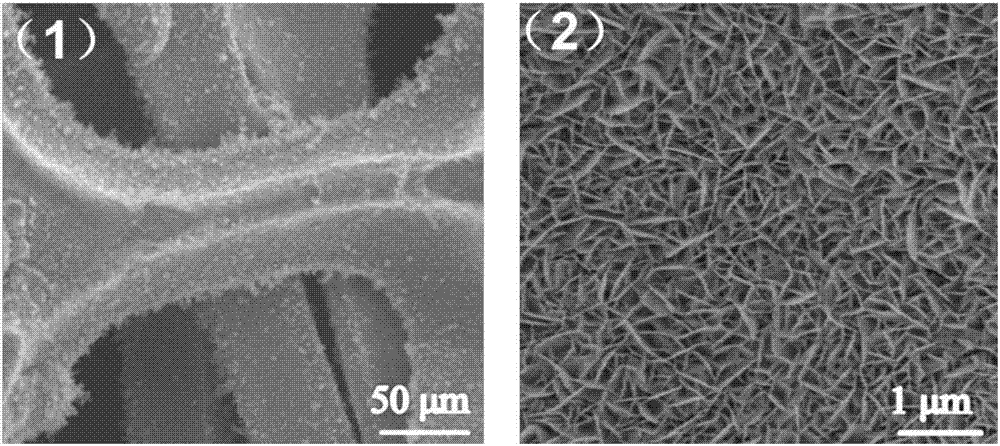

[0033] 1) Pretreatment of foamed nickel: Cut the foamed nickel into 2×4cm rectangular pieces, then place them in acetone, 1mol / L dilute hydrochloric acid solution and deionized water in sequence, and ultrasonically clean them for 15 minutes in an ultrasonic cleaner, and finally Dry overnight at 60°C in a drying oven.

[0034] 2) Preparation of nickel foam with iron ions and nickel ions on the surface: the nickel foam obtained in step 1) is put into the mixed aqueous solution of iron salt and nickel salt, wherein the concentration of iron ion is 11mmol / L, and the concentration of nickel ion is 33mmol / L, the solution volume is 30mL, and stirred for 20min, so that the surface of nickel foam is loaded with enough iron ions and nickel ions.

[0035] 3) Preparation of iron-nickel binary hydroxide-nickel foam composite electrode material: Weigh a certain amount of urea and add it to the beaker of step 2), the concentration of urea is 99mmol / L, stir and mix well, and move it i...

Embodiment 2

[0044] 1) Pretreatment of foamed nickel: Cut the foamed nickel into 2×4cm rectangular pieces, then place them in acetone, 1mol / L dilute hydrochloric acid solution and deionized water in sequence, and ultrasonically clean them for 15 minutes in an ultrasonic cleaner, and finally Dry overnight at 60°C in a drying oven.

[0045] 2) Preparation of nickel foam with iron ions and nickel ions on the surface: the nickel foam obtained in step 1) is put into the mixed aqueous solution of iron salt and nickel salt, wherein the concentration of iron ion is 15mmol / L, and the concentration of nickel ion is 30mmol / L, the solution volume is 30mL, and stirred for 20min, so that the surface of nickel foam is loaded with enough iron ions and nickel ions.

[0046] 3) Preparation of iron-nickel binary hydroxide-nickel foam composite electrode material: Weigh a certain amount of urea and add it to the beaker of step 2), the concentration of urea is 99mmol / L, stir and mix well, and move it i...

Embodiment 3

[0050] 1) Pretreatment of foamed nickel: Cut the foamed nickel into 2×4cm rectangular pieces, then place them in acetone, 1mol / L dilute hydrochloric acid solution and deionized water in sequence, and ultrasonically clean them for 15 minutes in an ultrasonic cleaner, and finally Dry overnight at 60°C in a drying oven.

[0051] 2) Preparation of nickel foam with iron ions and nickel ions on the surface: the nickel foam obtained in step 1) is put into the mixed aqueous solution of iron salt and nickel salt, wherein the concentration of iron ion is 22mmol / L, and the concentration of nickel ion is 22mmol / L, the solution volume is 30mL, and stirred for 20min, so that the surface of nickel foam is loaded with enough iron ions and nickel ions.

[0052] 3) Preparation of iron-nickel binary hydroxide-nickel foam composite electrode material: Weigh a certain amount of urea and add it to the beaker of step 2), the concentration of urea is 99mmol / L, stir and mix well, and move it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com