Formula milk powder for infant of one to three years old

A technology for formula milk powder and infants, applied in the field of formula milk powder and three-year-old infant formula milk powder, can solve the problems of allergies, prone to milk, imperfection, etc., to support growth and development, reduce the risk of infant milk protein allergy, and reduce the risk of infant milk protein allergy. Effects of protein allergy risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

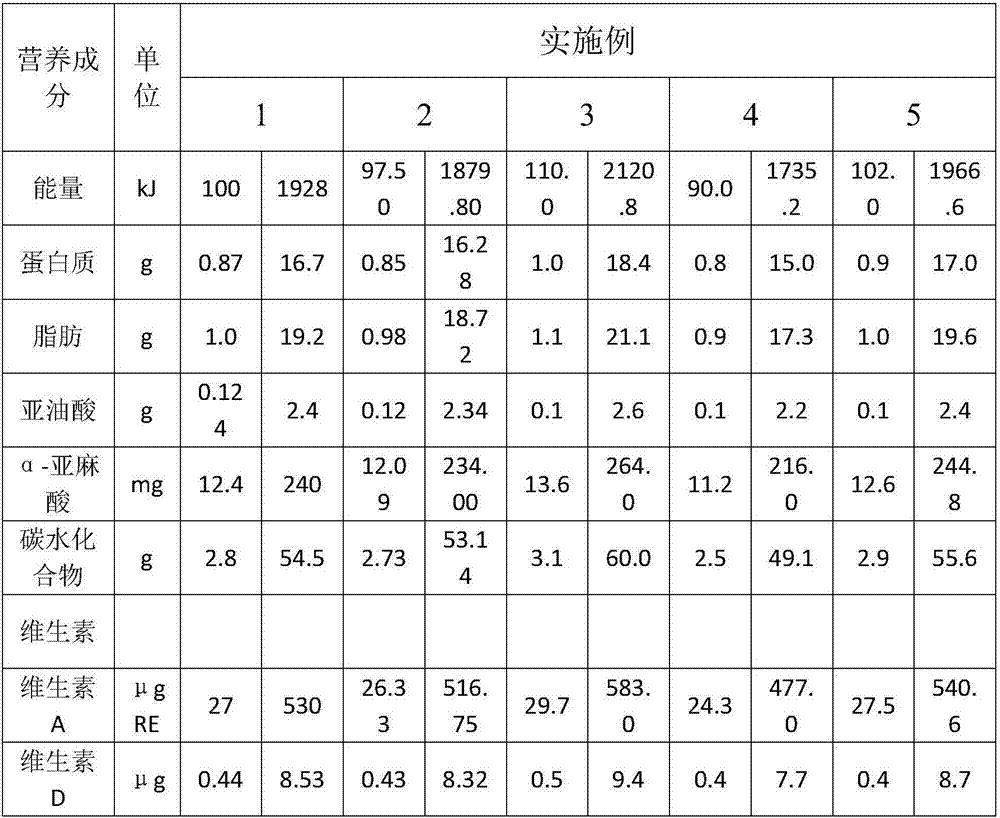

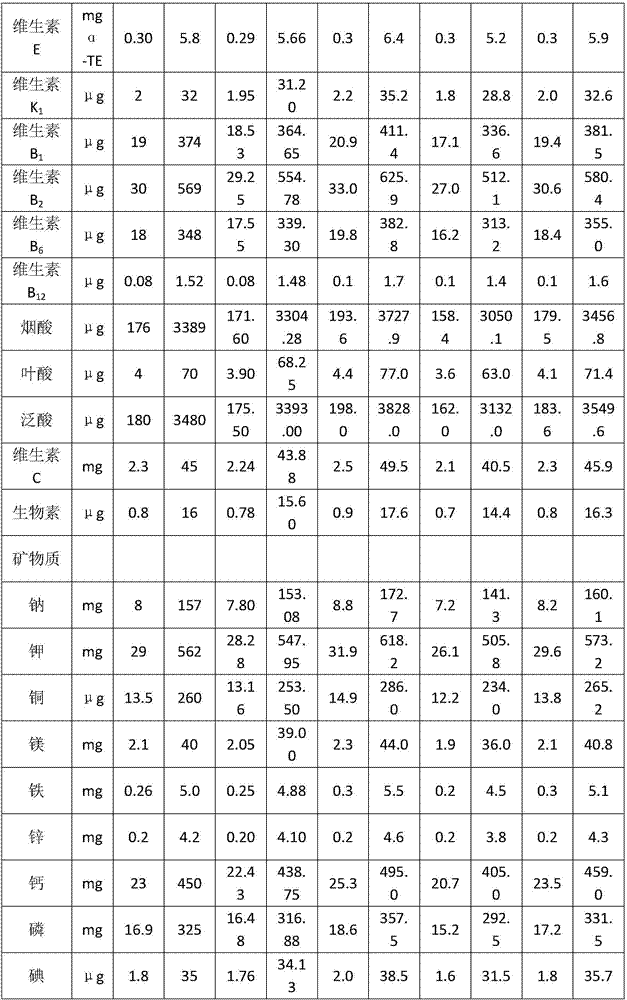

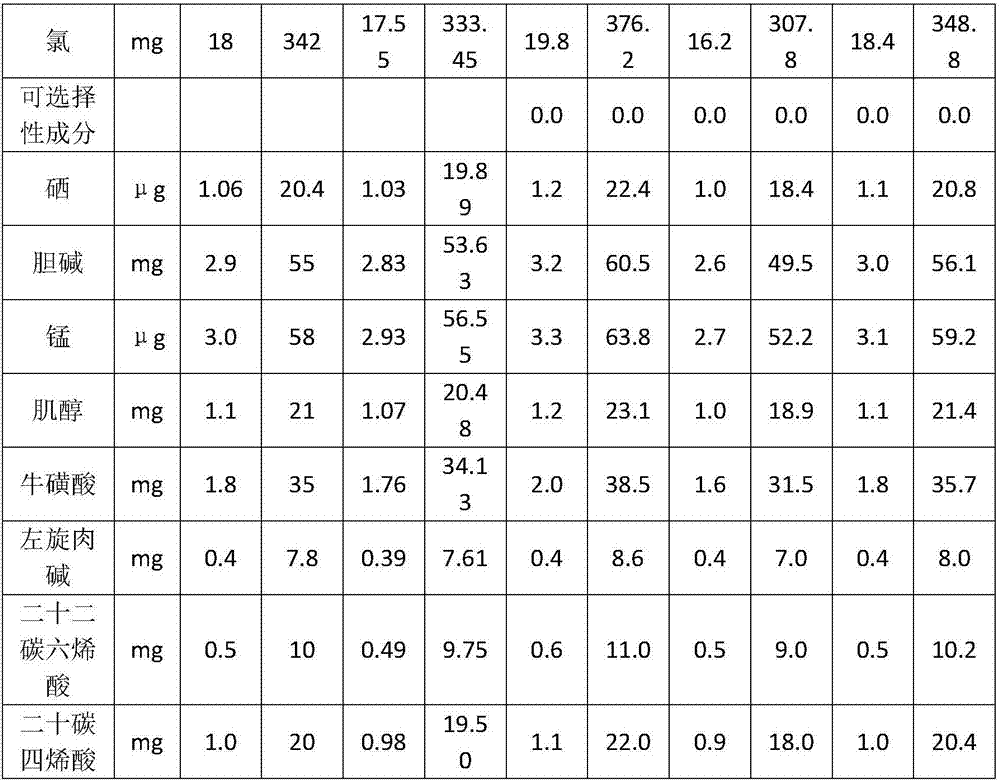

Examples

Embodiment 1

[0036] Prepare a kind of infant formula milk powder of one to three years old, this infant formula milk powder, by every 1000kg finished milk powder, described milk powder raw material consists of:

[0037] Base powder 599.85kg, desalted whey powder 187.45kg, skimmed milk powder 137.47kg, whole milk powder 24.99kg, concentrated whey protein powder 20.00kg, hydrolyzed whey protein powder 16.25kg, eicosatetraenoic acid 2.25kg, Docosahexaenoic acid 1.75kg, multivitamins 1.00kg and multiminerals 9.00kg.

[0038] In this preferred embodiment, the raw material composition of the base powder is set as 48% desalted whey powder, 30% vegetable oil, 18% skimmed milk powder, 2.2% lactose, and 1.8% balance . The composition of the vegetable oil includes by percentage: 35% palm oil, 32% rapeseed oil, 21% palm kernel oil and 12% sunflower oil.

[0039] The remaining raw materials are sodium citrate, tricalcium phosphate, potassium chloride, calcium carbonate, magnesium chloride, calcium ch...

Embodiment 2

[0043] Prepare a kind of infant formula milk powder of one to three years old, and this preferred embodiment 2 is compared with embodiment 1, only the base formula ratio is different, and wherein base powder, multivitamin and the raw material composition and percentage content are the same.

[0044] The content of the composite minerals is 7kg per 1000kg of finished milk powder, and the raw material composition of the composite minerals is the same as in Example 1.

[0045]The formula milk powder for infants is based on every 1000kg of finished milk powder. The raw materials of the milk powder are: 585kg of base powder, 198kg of desalted whey powder, 142.2kg of skimmed milk powder, 22kg of whole milk powder, 18.5kg of concentrated whey protein powder, hydrolyzed Whey protein powder 18kg, eicosatetraenoic acid 1.8kg, docosahexaenoic acid 2kg, multivitamins 1.5kg and multiminerals 11kg.

Embodiment 3

[0047] To prepare a formula milk powder for one to three-year-old infants, this preferred embodiment 3 is compared with embodiment 1, only the proportion of the basic formula is different, and the raw material composition and percentage content of the base powder and compound minerals are the same.

[0048] The content of the multivitamin per 1000kg of finished milk powder is 0.7kg, and the raw material composition of the multivitamin is the same as in Example 1.

[0049] The formula milk powder for infants is calculated on the basis of every 1000kg of finished milk powder. The raw materials of the milk powder are: 610kg of base powder, 188.3kg of desalted whey powder, 128kg of skimmed milk powder, 27kg of whole milk powder, 21kg of concentrated whey protein powder, hydrolyzed milk Albumin powder 14.5kg, eicosatraenoic acid 2kg, docosahexaenoic acid 1.5kg, multivitamins 0.7kg and multiminerals 7kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com