Drying device for coking desulfurized sulfur foam and desulfurized effluent

A technology for desulfurization waste liquid and drying device, which is applied to combined devices, inorganic chemistry, sulfur compounds, etc., can solve the problems of high operating cost and environmental pollution, and achieve the effect of solving high operating cost, solving environmental pollution and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

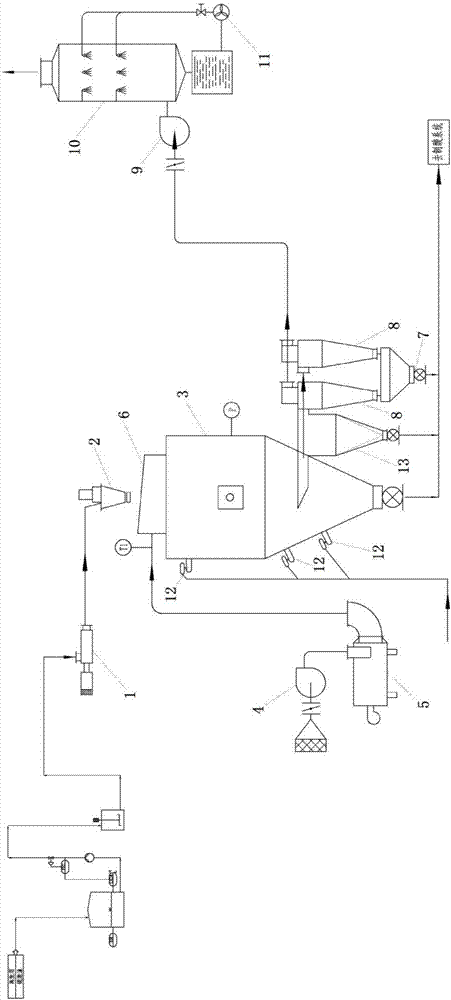

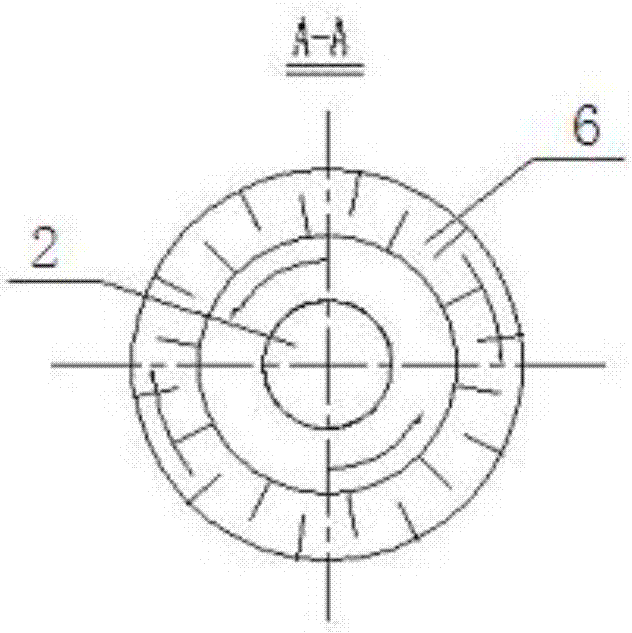

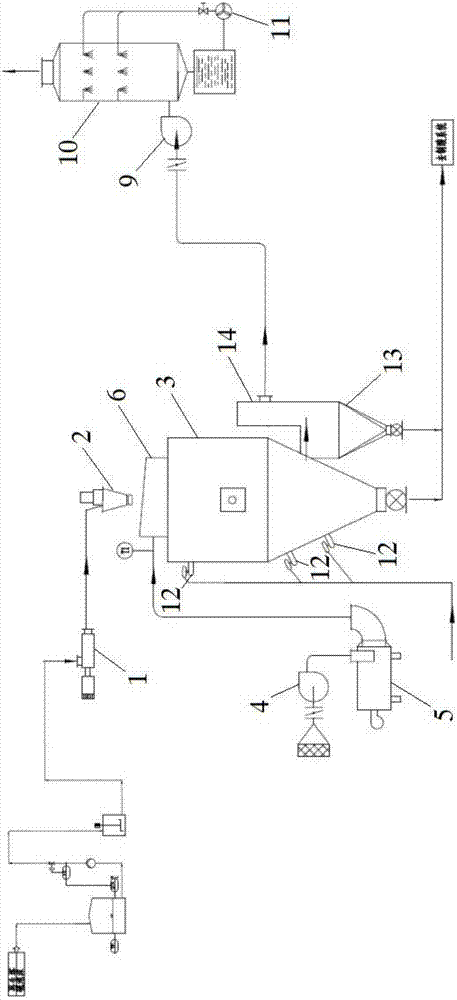

[0023] Such as figure 1 As shown, the coking desulfurization sulfur foam and desulfurization waste liquid drying device of the present invention comprises coking desulfurization sulfur foam and desulfurization waste liquid conveying equipment screw pump 1, concentration equipment centrifugal atomizer 2, drying equipment drying tower 3 and tail gas The treatment equipment is a cyclone separator 8, and the tail gas treatment equipment adopts two cyclone separators 8 connected in series. Among them, a settling device settling tank 13 is arranged between the drying tower 3 of the drying equipment and the cyclone separator 8 of the tail gas equipment to settle the particles in the dry tail gas discharged from the drying tower 3 of the drying equipment, so as to prevent the particles in the dry tail gas from entering the tail gas treatment In the cyclone s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com