Dehumidification rotating wheel and preparation method thereof

A runner and runner body technology, applied in separation methods, chemical instruments and methods, silicates, etc., can solve the problems of limited adsorption capacity of molecular sieves, and the adsorption properties are not as stable as molecular sieves, and achieve high stability, firm adsorption, and high stability. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The water glass solution used in this embodiment has a Baume degree of 47 and a modulus of 2.6.

[0041] A method for preparing a dehumidification runner includes the following steps:

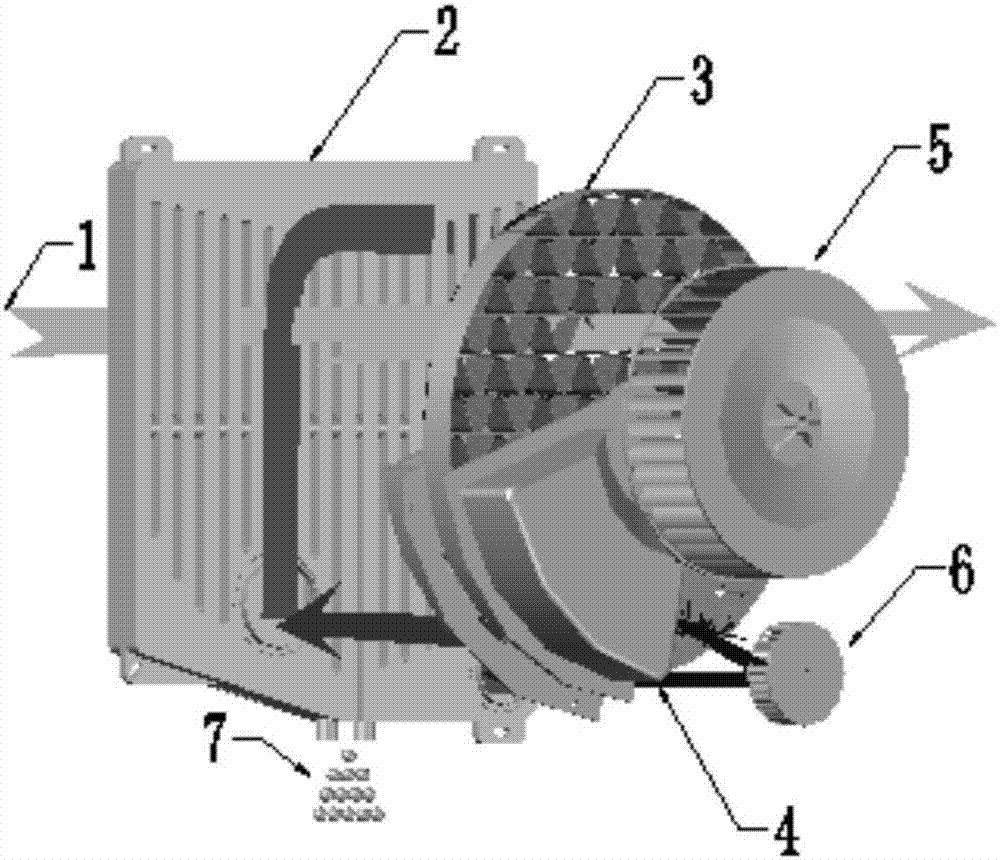

[0042] 1) Preparation of the runner body: spray styling glue on ceramic fiber paper with a thickness of 0.3mm and a width of 200mm, and press it into a corrugated shape with a corrugation height of 2mm and a corrugation pitch of 3.5mm; the ceramic fiber paper after pressing Coat the water glass solution on one side of the pressed ceramic fiber paper and bond and compact the uncompressed ceramic fiber paper with a thickness of 0.3mm; coat the water glass solution on the other side of the pressed molded fiber paper, Rolled into a wheel-shaped honeycomb with a diameter of 300mm and a thickness of 200mm;

[0043] 2) Preparation of the gel layer: the honeycomb runner body obtained in step 1) is immersed in a water glass solution, and dried at 115°C for 105 minutes to form a gel layer on the inner s...

Embodiment 2

[0048] The water glass solution used in this embodiment has a Baume degree of 45 and a modulus of 2.6.

[0049] A method for preparing a dehumidification runner includes the following steps:

[0050] 1) Preparation of the runner body: spray setting glue on carbon fiber paper with a thickness of 0.2mm and a width of 200mm, and press it to form a corrugated shape with a corrugation height of 2mm and a corrugation pitch of 3.5mm after pressing; Coat the water glass solution on the side, and bond the pressed carbon fiber paper with another uncompressed carbon fiber paper with a thickness of 0.2mm; coat the water glass solution on the other side of the pressed molded fiber paper and wind it up A wheel-shaped honeycomb body with a diameter of 200mm and a thickness of 200mm;

[0051] 2) Preparation of the gel layer: the honeycomb runner body obtained in step 1) is immersed in a water glass solution and dried at 110°C for 120 minutes to form a gel layer on the inner side wall of the honeyco...

Embodiment 3

[0055] The water glass solution used in this embodiment has a Baume degree of 48 and a modulus of 2.8.

[0056] A method for preparing a dehumidification runner includes the following steps:

[0057] 1) Preparation of runner body: spray setting glue on alumina fiber paper with a thickness of 0.1mm and a width of 200mm, and press it to form a corrugated shape with a corrugation height of 2mm and a corrugation pitch of 3.5mm; the alumina after pressing One side of the fiber paper is coated with water glass solution, and the pressed alumina fiber paper is bonded and compacted with another uncompressed alumina fiber paper with a thickness of 0.1 mm; the other side of the pressed fiber paper is coated The water-coated glass solution is rolled into a wheel-shaped honeycomb with a diameter of 250mm and a thickness of 200mm;

[0058] 2) Preparation of the gel layer: the honeycomb runner body obtained in step 1) is immersed in a water glass solution and dried at 110°C for 120 minutes to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com