Carbon dioxide electric arc welding sprayer based on thermal infrared radiation

A thermal infrared and arc welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as nozzle blockage and porosity, and achieve the effect of reducing the production of CO2 gas, promoting decomposition, and increasing the melting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

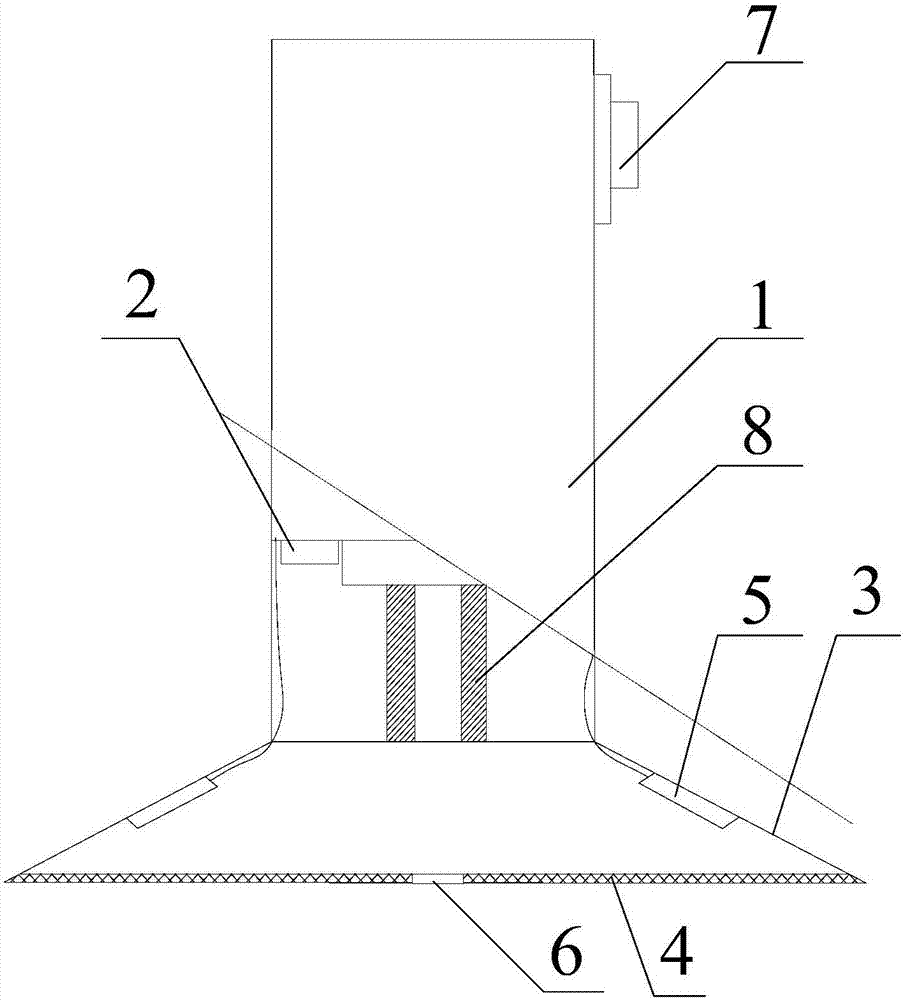

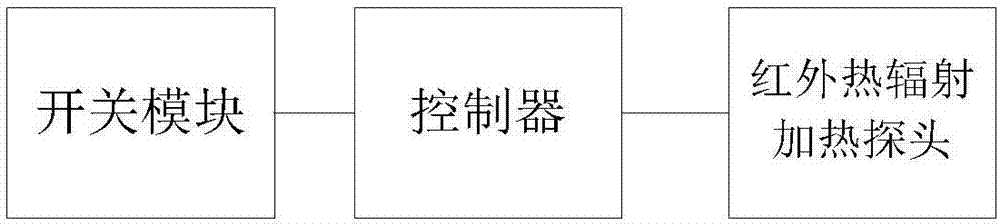

[0023] Such as figure 1 , 2 As shown, the present invention is based on thermal infrared radiation of CO 2 The arc welding spray head includes a spray tube 1, and CO is arranged in the spray tube 1 2 The gas nozzle 2 is also provided with a protective cover 3 at the bottom of the spray tube 1, the center line of the protective cover 3 coincides with the axis of the spray tube 1, one end of the protective cover 3 is sealed with the end face of the spray tube 1, and the other end is provided with a A mesh cover 4, the inner cavity of the protective cover 3 is connected with CO 2 The gas nozzle 2 communicates, and the inner diameter of the protective cover 3 increases linearly along the direction of the spray tube 1 pointing to the net cover 4; at least one infrared thermal radiation heating probe 5 is also installed on the inner wall of the protective cover 3, A controller and a switch module 7 are also provided, and the infrared heat radiation heating probe 5 and the switch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com