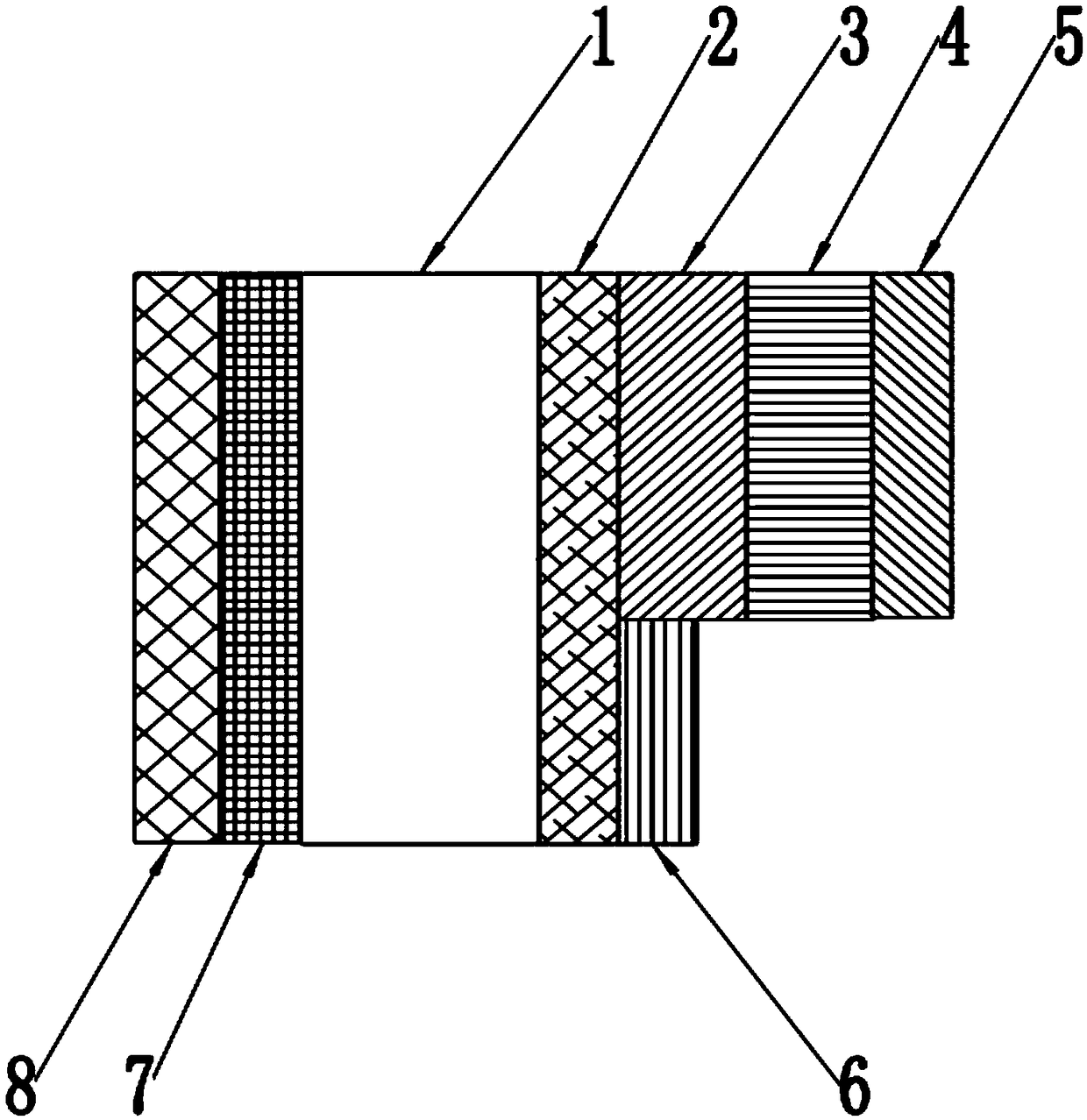

A thin half-covered TV metal backplane

A technology for metal backplanes and TV sets, applied in metal layered products, coatings, chemical instruments and methods, etc., can solve problems such as insufficient hardness, overall thickness of TV sets, and raised wings at both ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0043] Embodiment 1~Example 3 The specific preparation method of the metal backboard of the thin half-coated TV set is as follows:

[0044]Unwinding and unwinding, after cleaning, correcting the deviation through a deviation correcting device; using a chromate chemical pretreatment solution with a concentration of 20wt% to passivate the front and rear sides of the galvanized steel sheet substrate (thickness 0.8mm), and dry to obtain a chemical coating; Roll-coat the anti-corrosion and stain-resistant coating on the lower part of the chemical coating on the back side and the chemical coating on the front side, with a thickness of 15 μm, and dry it with hot air at 75 ° C to obtain an anti-corrosion and stain-resistant coating; coat the upper part of the chemical coating on the rear side Coated with polyurethane glue, the wet film thickness is 25 μm, cured at 220 ° C to obtain a polyurethane adhesive layer; at 220 ° C, a PET film was attached on the adhesive layer, with a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com