A kind of preparation method of high-purity lithium fluoride

A lithium fluoride, high-purity technology, applied in the field of preparation of high-purity lithium fluoride, can solve the problems of lack of lithium fluoride and inaccurate recovery process of harmful gases, so as to reduce the emission of harmful gases, improve the accuracy, and improve the process flow. The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

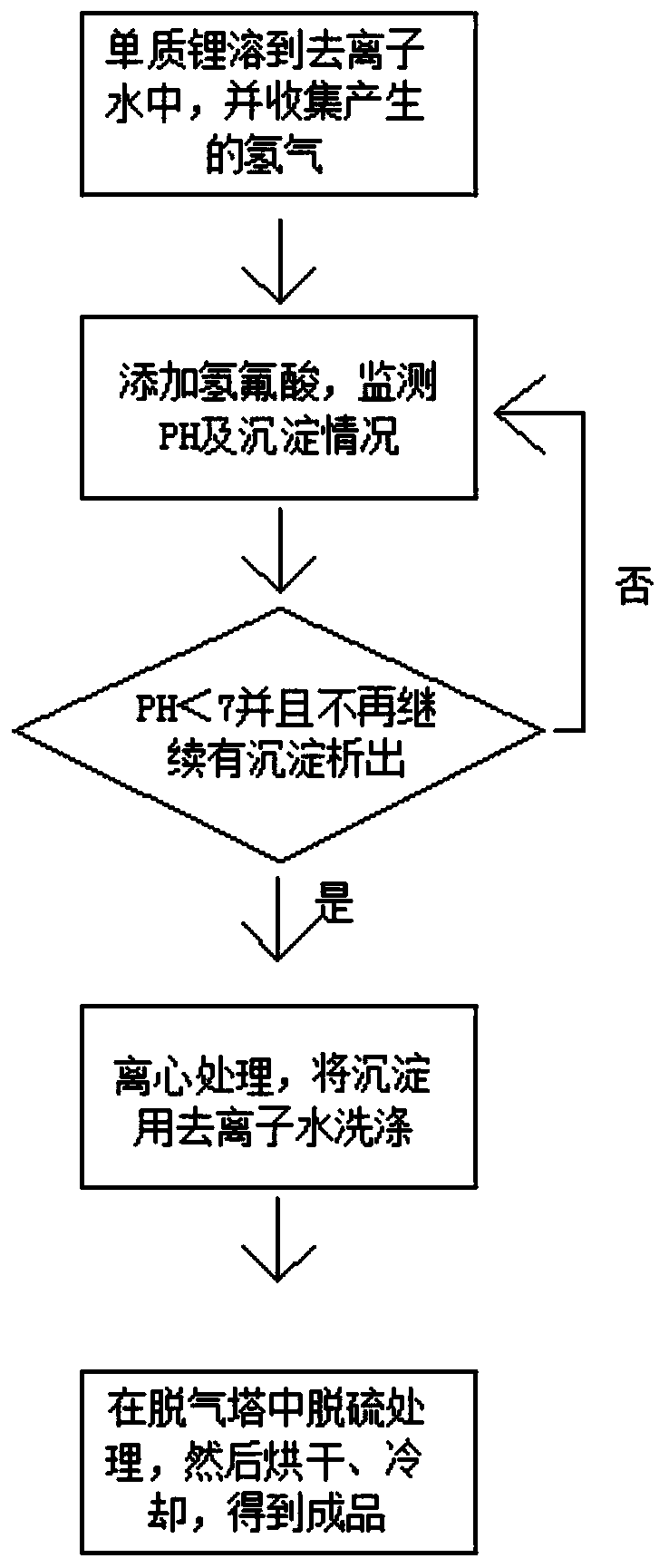

[0030] A preparation method for high-purity lithium fluoride, comprising the following steps:

[0031] S1: Dissolve elemental lithium metal at a ratio of 1:100 in deionized water at a temperature of 2°C. During the dissolving process after placing lithium metal in deionized water, seal the gas collection hood of the gas collection device to the container. On the deionized water container, turn on the vacuum pump on the gas collection device, and pump the generated hydrogen into the gas collection bag connected to the vacuum pump;

[0032] S2: After the metal lithium is completely dissolved, slowly add a hydrofluoric acid solution with a concentration of 99% to the solution and stir to make the lithium fluoride precipitate slowly, and place a pH value detection device in the solution;

[0033] S3: When the pH of the solution is less than 7 and lithium fluoride is no longer precipitated in the solution, stop adding the hydrofluoric acid solution and let stand for 0.5h;

[0034]...

Embodiment 2

[0038] A preparation method for high-purity lithium fluoride, comprising the following steps:

[0039] S1: Dissolve elemental lithium metal in deionized water at a temperature of 5°C at a ratio of 1:100. During the dissolution process after placing lithium metal in deionized water, seal the gas collection hood of the gas collection device to the container. On the deionized water container, turn on the vacuum pump on the gas collection device, and pump the generated hydrogen into the gas collection bag connected to the vacuum pump;

[0040] S2: After the metal lithium is completely dissolved, slowly add a hydrofluoric acid solution with a concentration of 99% to the solution and stir to make the lithium fluoride precipitate slowly, and place a pH value detection device in the solution;

[0041] S3: When the pH of the solution is less than 7 and lithium fluoride is no longer precipitated in the solution, stop adding the hydrofluoric acid solution and let stand for 0.5h;

[0042...

Embodiment 3

[0046] The purity verification experiment of lithium fluoride:

[0047] Experimental method: number the lithium fluoride prepared in Example 1 and Example 2 as A and B; C is a high-purity lithium fluoride sample produced by a traditional lithium fluoride production process. Use the electrode method to detect and analyze the composition of lithium fluoride in A, B and C.

[0048] The experimental results are shown in Table 1:

[0049] Table 1 Lithium fluoride sample composition

[0050] Test sample

[0051] Analysis of experimental results: the purity of lithium fluoride prepared by the preparation method of the present invention is 99.41% and 99.58%, respectively. While the purity of lithium fluoride produced by the traditional lithium fluoride production process is 99.12%, it can be seen that the purity of lithium fluoride produced by the preparation method of the present invention is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com