Efficient backwash method for biofilter

A biological filter and backwashing technology, applied in the direction of separation methods, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of wasting water resources and electric energy, affecting the effect of biochemical treatment, increasing one-time investment, etc., and achieve saving Operating costs, reducing one-time investment, and improving the effect of biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] A kind of biofilter high-efficiency backwashing method of the present invention, biofilter 1 is respectively newly-built biofilter or in-use biofilter; comprises the following steps:

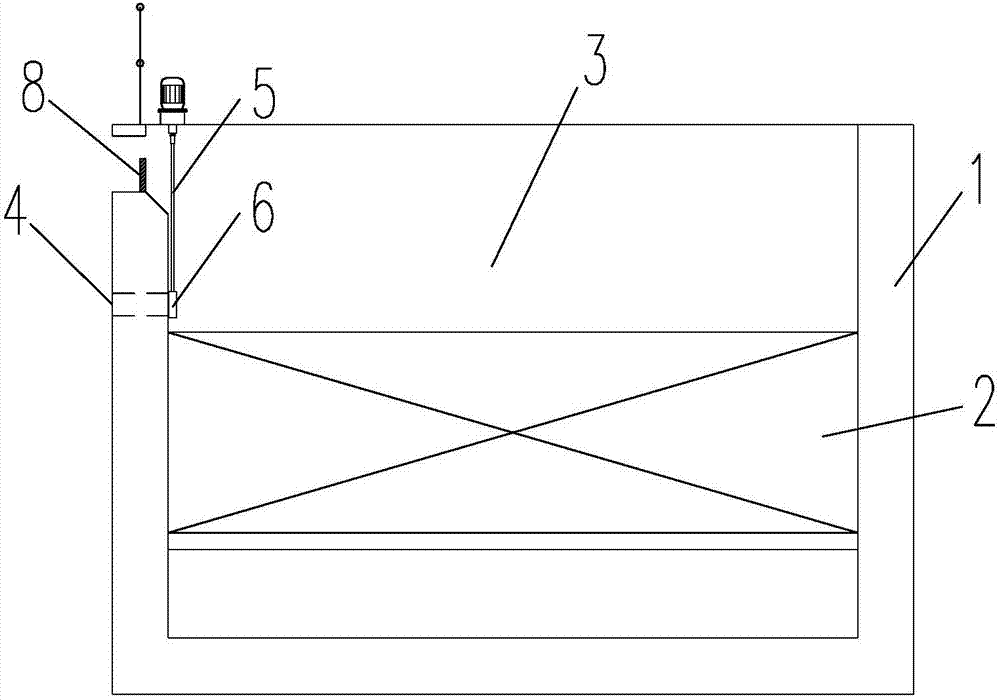

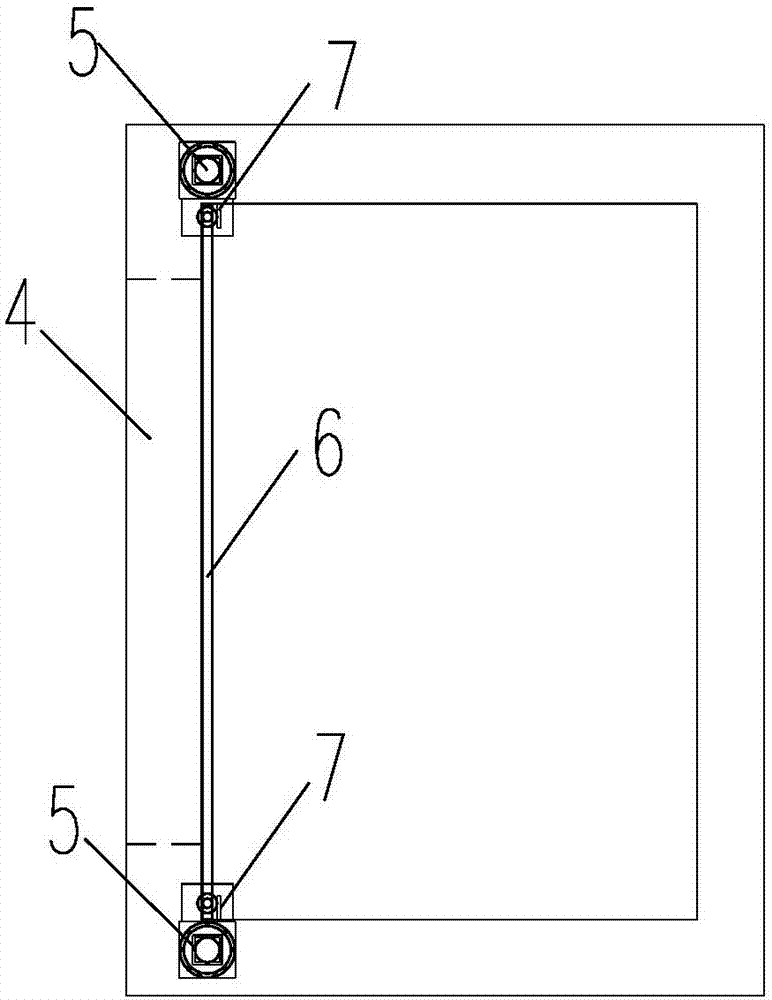

[0029] 1) if figure 1 , figure 2 As shown, for the new biofilter 1, a strip-shaped backwash drain 4 is provided along the length direction on the outlet side pool wall below the backwash outlet weir 8 and above the filter material layer 2, and an electric drainage device is provided; The electric drainage device is provided with a drainage baffle 6, the drainage baffle 6 is attached to the pool wall and covers the backwash drain 4, and the drainage baffle 6 can be lifted and lowered by the drainage driving device to realize backwash drainage Closing or opening of port 4;

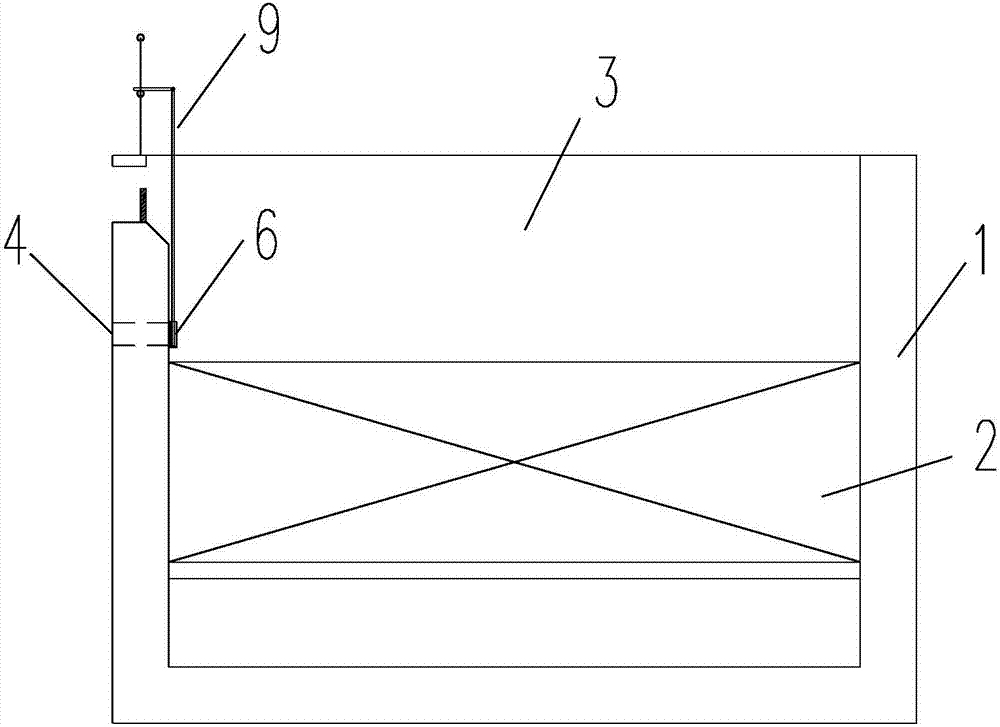

[0030] Such as image 3 , Figure 4 As shown, for the biofilter 1 in use, a recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com