Brewing method of fruit aroma litchi wine

A lychee wine, fruit-flavored technology, applied in microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problem of decreased ester content, uncontrollable fermentation process, and weak fruit flavor of lychee wine. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

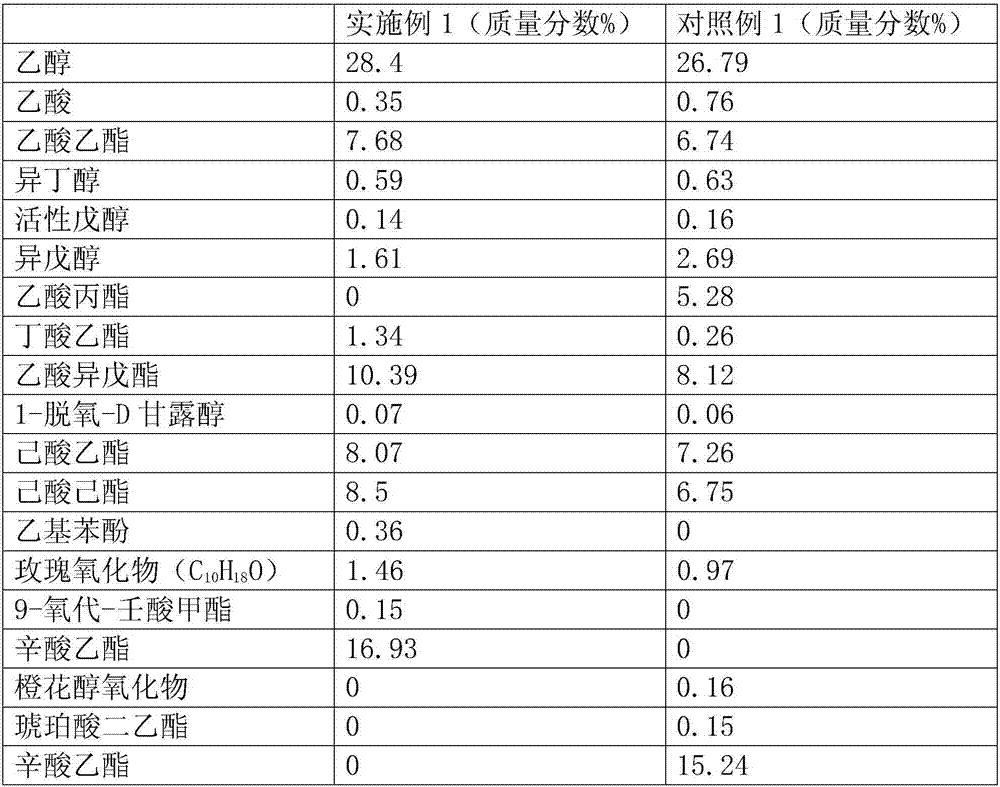

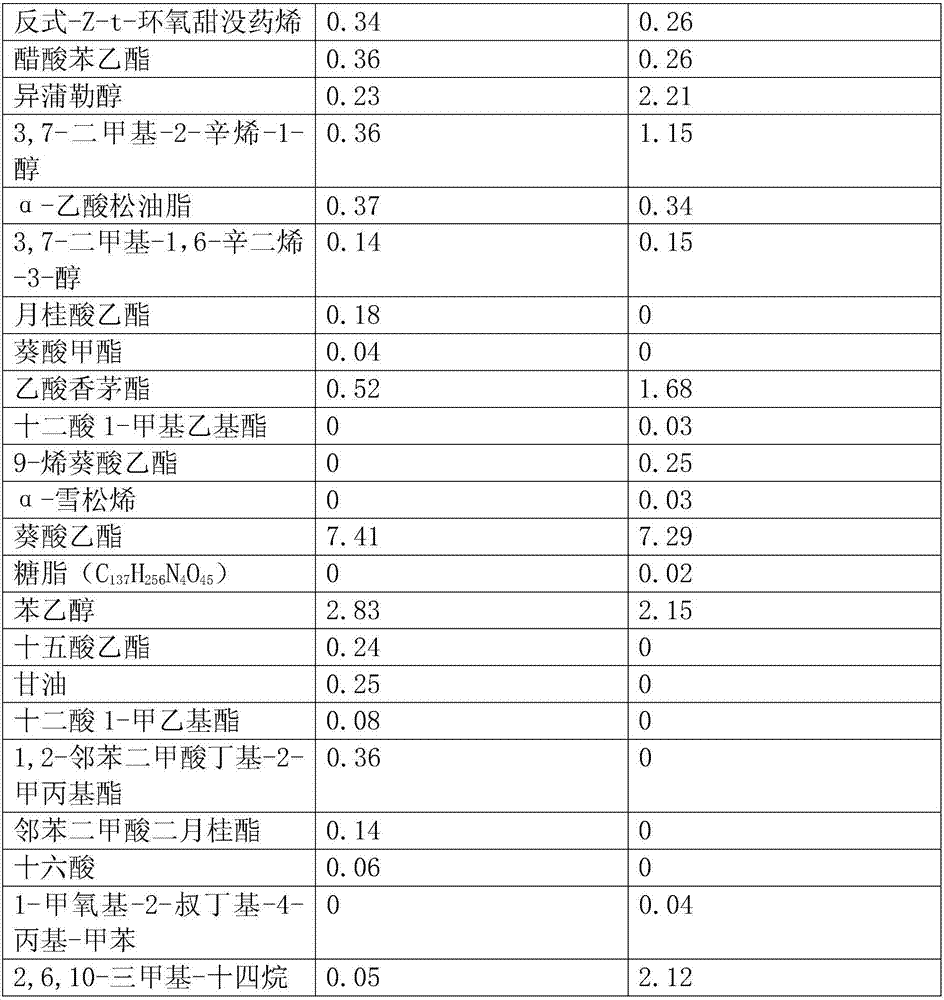

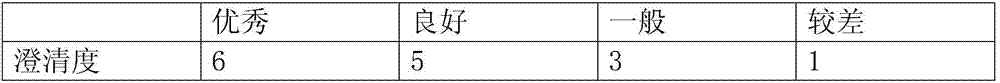

Examples

Embodiment 1

[0019] 1) Peel the lychee, remove the core, take the lychee pulp and add water to make a pulp. The weight ratio of the pulp to water is 1:1. 200mg / L lychee pulp, pectinase activity 27000U / g, enzymatic hydrolysis at 40°C for 20min, inactivate the enzymolysis solution, filter, and the filtrate is lychee juice;

[0020] 2) Add water to the pineapple pulp, the weight ratio of pulp to water is 1:1, adjust the pH value of pineapple pulp to 4.0, add pectinase for enzymatic hydrolysis, the amount of pectinase added is 200mg / L pineapple pulp, pectin Enzyme activity is 27000U / g; enzymolyze at 40°C for 20min, inactivate the enzymolyzate, filter, and the filtrate is pineapple juice;

[0021] 3) Mix lychee juice and pineapple juice in a weight ratio of 10:0.1, adjust the sugar content of the mixed juice to 16%, inoculate active dry yeast with a weight of 0.01% of the mixed juice, and ferment at 20°C for 15 days to obtain raw wine;

[0022] 4) Centrifuge the original wine, and age the filt...

Embodiment 2

[0028] 1) Peel and pit the lychee, take the lychee pulp and add water to make a pulp, the weight ratio of the pulp to water is 1:3, adjust the pH value of the lychee pulp to 5.0, add pectinase for enzymatic hydrolysis, and the amount of pectinase added is 220mg / L lychee pulp, pectinase activity 35000U / g, enzymatically hydrolyze at 50°C for 30min, inactivate the enzymatic hydrolyzate, filter, and the filtrate is lychee juice;

[0029] 2) Add water to the pineapple pulp, the weight ratio of pulp to water is 1:3, adjust the pH value of pineapple pulp to 5.0, add pectinase for enzymatic hydrolysis, and the amount of pectinase added is 220mg / L pineapple pulp, pectin Enzyme activity is 35000U / g; enzymolysis at 50°C for 30 minutes, inactivation of the enzymolysis solution, filtration, and the filtrate is pineapple juice;

[0030] 3) mix lychee juice and pineapple juice at a weight ratio of 10:0.15, adjust the sugar content of the mixed juice to 18%, inoculate active dry yeast with a ...

Embodiment 3

[0033] 1) Peel and pit the lychee, take the lychee pulp and add water to make a pulp, the weight ratio of the pulp to water is 1:2, adjust the pH value of the lychee pulp to 4.5, add pectinase for enzymatic hydrolysis, and the amount of pectinase added is 210mg / L lychee pulp, pectinase activity 30000U / g, enzymolysis at 45°C for 25min, inactivate the enzymolysis solution, filter, the filtrate is lychee juice;

[0034] 2) Add water to the pineapple pulp, the weight ratio of pulp to water is 1:2, adjust the pH value of pineapple pulp to 4.5, add pectinase for enzymatic hydrolysis, and the amount of pectinase added is 210mg / L pineapple pulp, pectin Enzyme activity is 30000U / g; enzymolysis at 45°C for 25 minutes, inactivation of the enzymolysis solution, filtration, and the filtrate is pineapple juice;

[0035] 3) mix lychee juice and pineapple juice at a weight ratio of 10:0.13, adjust the sugar content of the mixed juice to 17%, inoculate active dry yeast with a weight of 0.015% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com