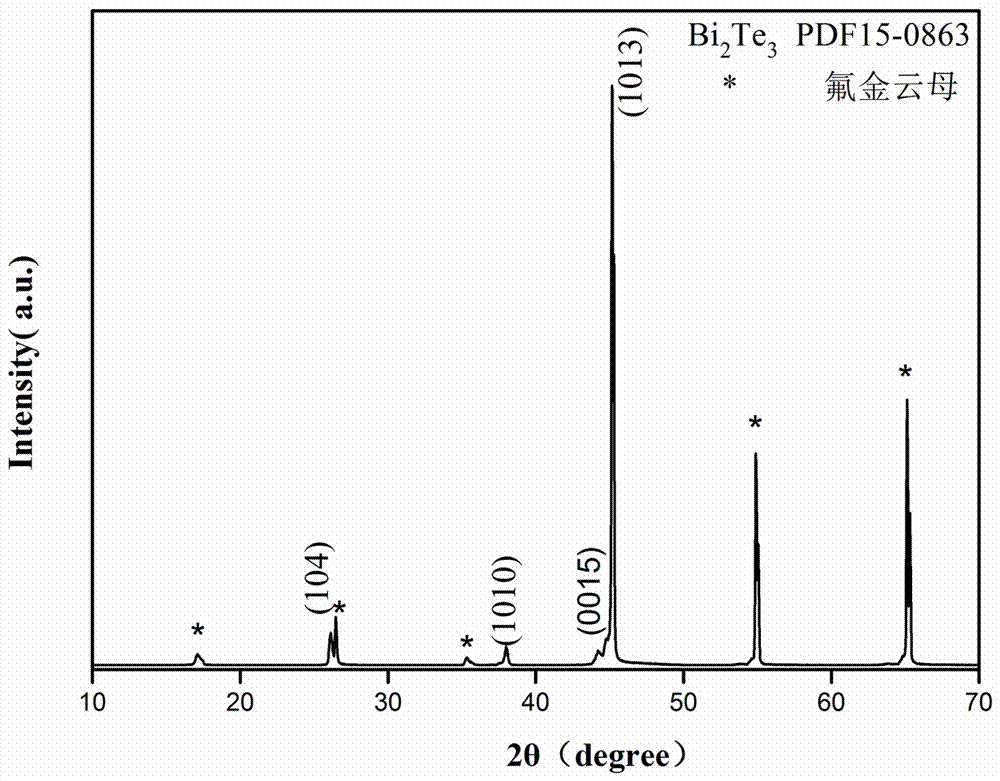

Bismuth telluride nanosheet film of spiral structure and preparing method of bismuth telluride nanosheet film

A helical structure, bismuth telluride technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of complex bismuth telluride nanostructure process, time-consuming, high cost, easy operation and high cost. The effect of promotion, less environmental pollution, and broad research value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

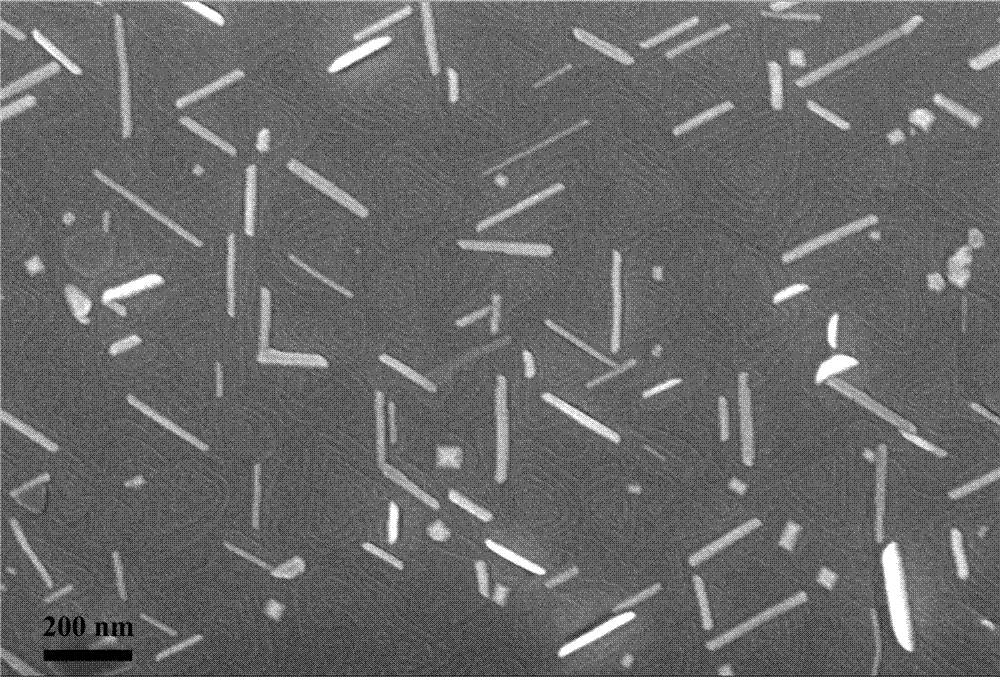

Embodiment 1

[0017] Before the experiment, put the fluorophlogopite in absolute ethanol for ultrasonic cleaning, then put it in a plasma cleaner and blow it with nitrogen to clean it and dry it. In the crucible, add 2.5mmol of Bi 2 Te 3 High-purity powder, placed in the heating tank of the evaporation source of the instrument. Fix the cleaned fluorphlogopite on the sample stage. Place the sample stage on the area above the evaporation source where the sample stage can be fixed, and adjust the distance between the substrate sample stage and the evaporation source to 10cm. Turn on the compound molecular pump unit to evacuate to 9*10 -5 Pa, the substrate was heated to 380 °C. After the substrate temperature is stable, heat the evaporation source to 360°C, and wait for the instrument to be vacuumed to 5*10 -5 Pa, open the baffle under the substrate and start coating. React at this temperature for 10 minutes, close the evaporation source and substrate baffle, adjust the evaporation source...

Embodiment 2

[0019] Before the experiment, put the fluorophlogopite in absolute ethanol for ultrasonic cleaning, then put it in a plasma cleaner and blow it with nitrogen to clean it and dry it. In the crucible, add 2.5mmol of Bi 2 Te 3 High-purity powder, placed in the heating tank of the evaporation source of the instrument. Fix the cleaned fluorphlogopite on the sample stage. Place the sample stage on the area above the evaporation source where the sample stage can be fixed, and adjust the distance between the substrate sample stage and the evaporation source to 10cm. Turn on the compound molecular pump unit to evacuate to 9*10 -5 Pa, the substrate was heated to 380 °C. After the substrate temperature is stable, heat the evaporation source to 360°C, and wait for the instrument to be vacuumed to 5*10 -5 Pa, open the baffle under the substrate and start coating. React at this temperature for 30 minutes, close the evaporation source and substrate baffle, adjust the evaporation source...

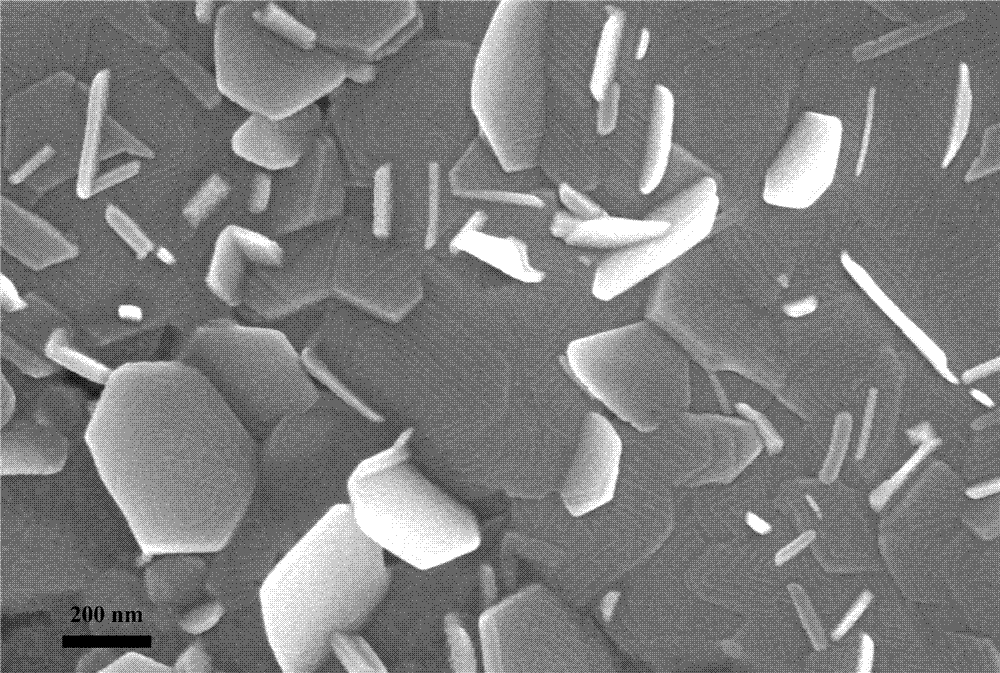

Embodiment 3

[0021] Before the experiment, put the fluorophlogopite in absolute ethanol for ultrasonic cleaning, then put it in a plasma cleaner and blow it with nitrogen to clean it and dry it. In the crucible, add 2.5mmol of Bi 2 Te 3 High-purity powder, placed in the heating tank of the evaporation source of the instrument. Fix the cleaned fluorphlogopite on the sample stage. Place the sample stage on the area above the evaporation source where the sample stage can be fixed, and adjust the distance between the substrate sample stage and the evaporation source to 10cm. Turn on the compound molecular pump unit to evacuate to 9*10 -5 Pa, the substrate was heated to 380 °C. After the substrate temperature is stable, heat the evaporation source to 340°C, and wait for the instrument to be vacuumed to 5*10 -5 Pa, open the baffle under the substrate and start coating. React at this temperature for 10 minutes, close the evaporation source and substrate baffle, adjust the evaporation source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com