Lifting construction method of plurality of steel galleries between towers

A construction method and technology of steel corridors, which can be used in construction, building construction, etc., can solve the problems of consuming materials, labor and time, safety is not guaranteed, consuming materials, time, etc., and save energy and time. , saving installation measures, reducing the effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described below in conjunction with accompanying drawing and embodiment:

[0039]For multiple steel corridors between the twin towers, it is difficult to assemble such a heavy steel structure on the roof of the basement one by one, then lift it up a certain distance, and then connect it to the towers. The requirements are high, especially the assembly process on the top of the basement roof lasts for a long time, so that the basement roof is under great stress for a long time, its bearing capacity is far from sufficient, it is prone to cracking, and its safety cannot be guaranteed.

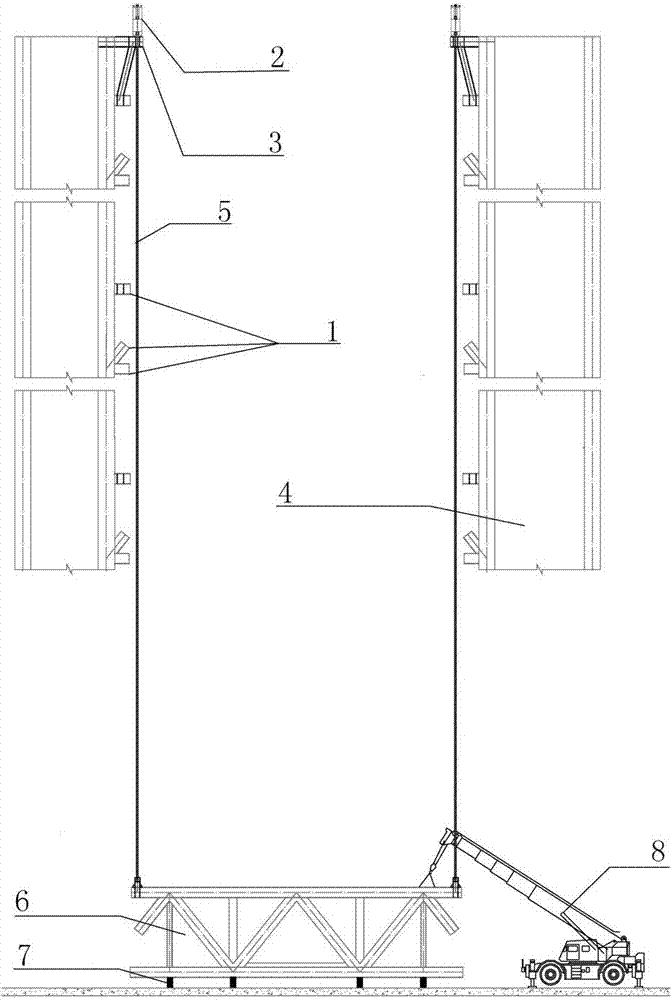

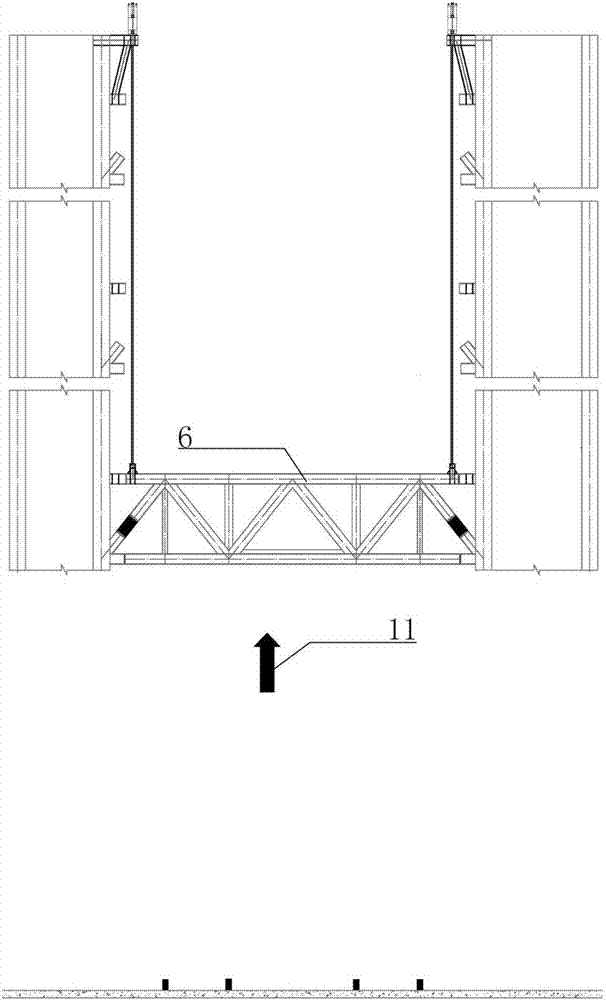

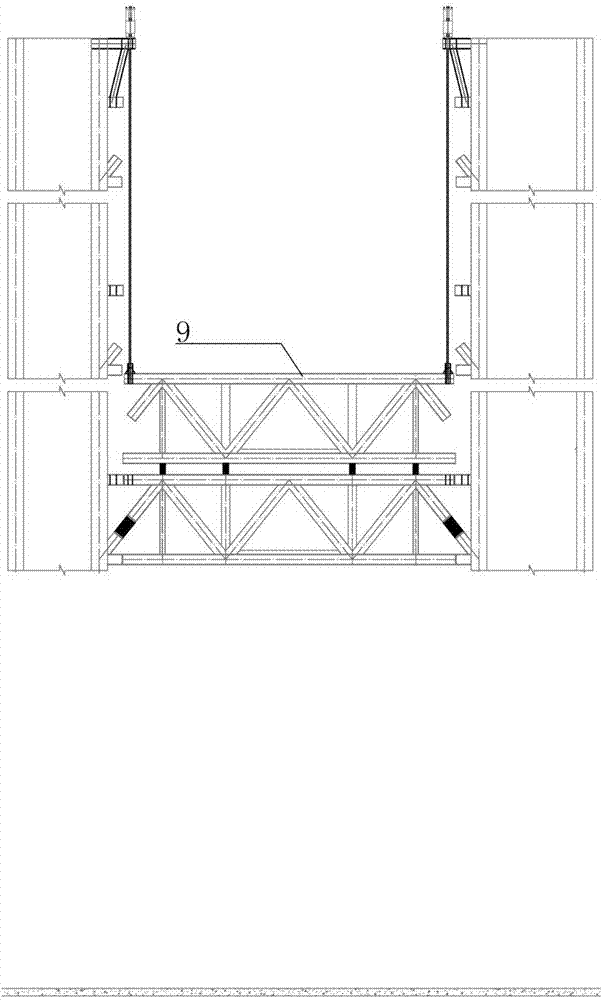

[0040] The present invention is a lifting construction method for a plurality of steel corridors between towers. The plurality of steel corridors are connected between the double towers 4, and the lifting sequence is steel corridor 6 in the low area, steel corridor 9 in the middle area, and steel corridor in the high area. Corridor 10, comprising the steps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com