Heat network grading heating system using small steam turbine and adjusting method thereof

A technology of hierarchical heating and heating network heaters, applied in heating methods, heating systems, hot water central heating systems, etc., can solve problems such as loss of available energy, reduce irreversible losses, good energy-saving benefits and promotion value, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

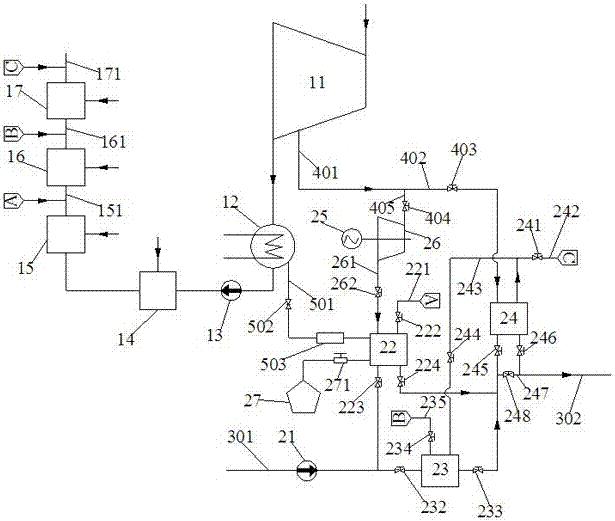

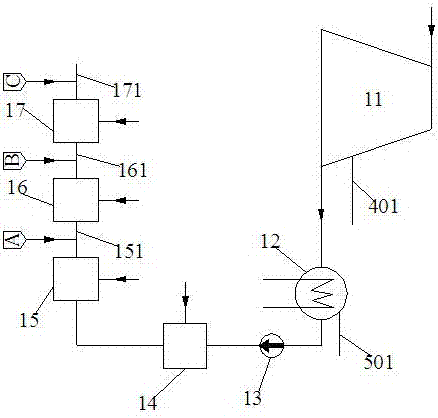

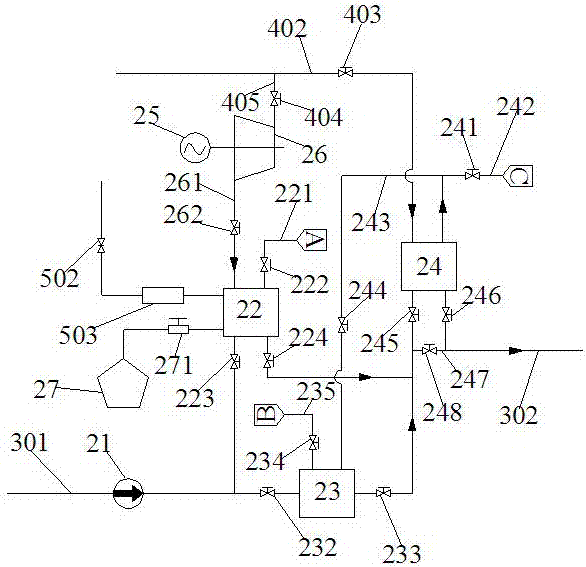

[0031] see Figure 1 ~ Figure 3 In this embodiment, the heat network staged heating system using small steam turbines includes a thermoelectric unit system and a heating system.

[0032] The thermoelectric unit system includes extraction condensing turbine 11, main condenser 12, condensate pump 13, eight-stage low-intensity heater 14, seven-stage low-increase heater 15, six-stage low-increase heater 16, and five-stage low-increase heater 17 , the extraction condensing turbine 11, the main condenser 12, the condensate pump 13, the eight-stage low-plus heater 14, the seven-stage low-plus heater 15, the six-stage low-plus heater 16, and the five-stage low-plus heater 17 are connected in sequence.

[0033] The extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com