High-quality milk pasteurizing equipment valve response time measuring method

A technology of response time and sterilization equipment, applied in the direction of measuring device, measuring heat, testing of mechanical parts, etc., can solve the problem of insufficient control accuracy of pasteurized milk sterilization intensity, achieve optimization of closing time, optimization of fluid temperature change, measurement of simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Valve Response Time Test

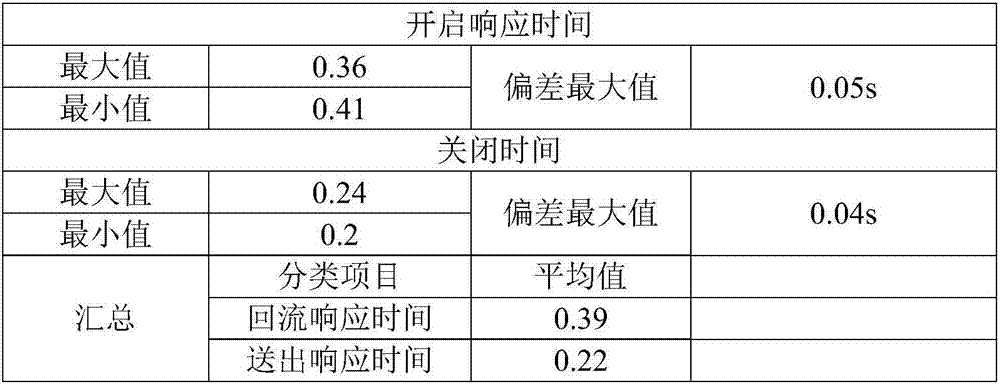

[0041] Test process: 10.1 tons of soft water was used to simulate pasteurized fresh milk sterilization process, and the temperature was 85±2°C. Detect and analyze the working principle of the temperature sensor, connect an analog temperature resistor in parallel, and realize the valve opening and closing trigger through switch simulation. Select the V104 valve for testing: Manually set the sterilization temperature lower than the safe temperature. After the sensor receives the temperature change, press the stopwatch immediately. After seeing the V104 valve starts to move, press the stopwatch again. This time is the response time for the valve to close. Use a stopwatch Record the response time of return and send. And the specific numerical data are shown in Table 1-2.

[0042] Table 1: Valve Response Times

[0043] Valve status Response time (s) Function open 0.38 reflow close 0.24 send out open 0.40 re...

Embodiment 2

[0048] Optimization of valve response time for high-quality milk pasteurization equipment

[0049] (1) According to the response time of the valve opening or closing measured in embodiment 1, T 开0 =0.41,T 关0 =0.24, the maximum deviation is 0.05 seconds.

[0050] (2) Determination of the fluid flow rate in the pasteurization equipment: according to the conventional pasteurization process, input milk, time the time from the milk flow out of the outlet to the reception of 40L milk, milk flow time (S): 14.08s, 13.98s , 14.04s, 13.93s, 13.85s, 13.87s, with an average of 13.96s. Volume flow Q = received milk volume V / reception time T.

[0051] Calculate the distance from the outlet of the insulation pipe of the pasteurization equipment to the valve, and calculate the position from the outlet of the insulation pipe to the valve based on the inner diameter of the pipe, and calculate the internal volume V of the pipe 0 , V 0 =0.00314 cubic meters. Calculate the flow time T of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com