Thermal Energy Harvester Based on Magnetic Phase Change Alloy-Pyroelectric Material

A heat energy collection and pyroelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problems of low conversion efficiency and achieve high conversion efficiency, Convenient preparation, energy-saving and high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

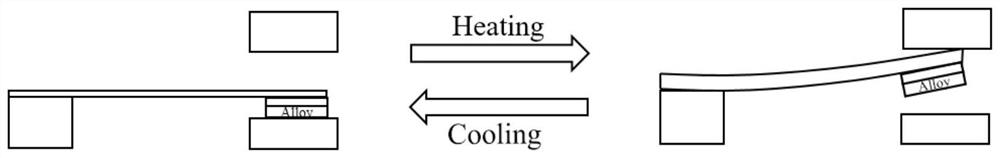

[0041] The invention relates to the antiferromagnetic-ferromagnetic phase change alloy used in the thermal energy collector is a Heusler (Heusler) type NiMnInCo alloy, and the composition is Ni 45 mn 36.91 In 13.09 co 5 . The antiferromagnetic-ferromagnetic phase change alloy uses high-purity metal elements Ni, Co, Mn and In as raw materials, and accurately proportions the metal elements according to the alloy expression, and is prepared by arc melting; smelted in high-purity argon gas It is carried out under the protection of atmosphere; the melted alloy is annealed at 850°C for 72 hours, then quenched and sized by wire cutting; finally, the energy harvester is built according to the design drawing. The prepared thermal energy collector can realize thermal energy collection for a constant heat source at 80°C.

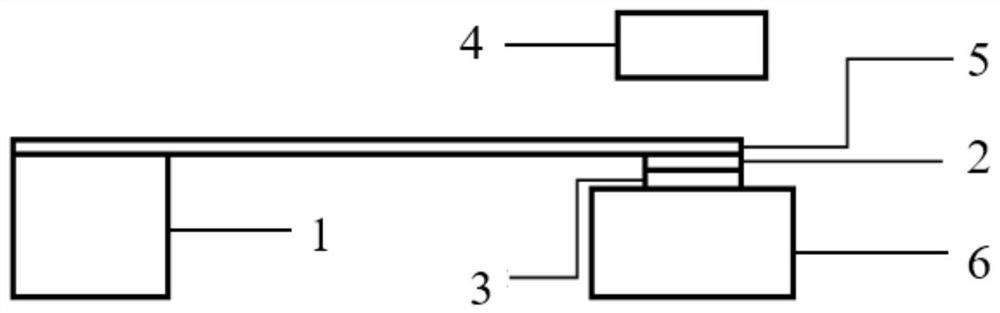

[0042] Such as figure 1 Shown is a schematic structural diagram of a thermal energy collector based on a magnetic phase change alloy / pyroelectric material. Such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com