Method for detecting content of gypsum particles in smoke of desulphuration outlet

A technology of particle content and detection method, which is applied in the field of electric power industry, can solve the problems of inability to reflect the real situation of the flue and inaccurate detection, and achieve the effect of reducing accidental errors and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

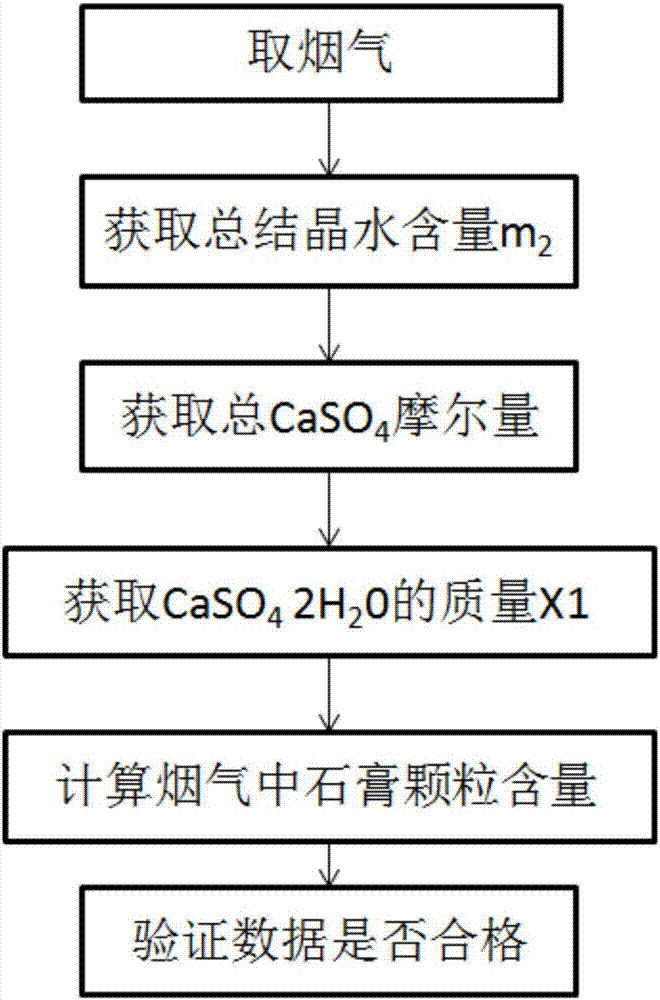

[0040] Such as figure 1 As shown, a method for detecting the content of gypsum particles in the desulfurization outlet flue gas of the present embodiment includes the following steps:

[0041](1) Use two heatable smoke sampling guns with built-in glass fiber filter membranes (the operating temperature is 100°C) to take 1000L of flue gas in the same measuring hole at the desulfurization outlet; the glass fiber filter membrane has a pore size of 0.24 The μm glass fiber filter membrane is made of silica and does not contain calcium ions and sulfate ions;

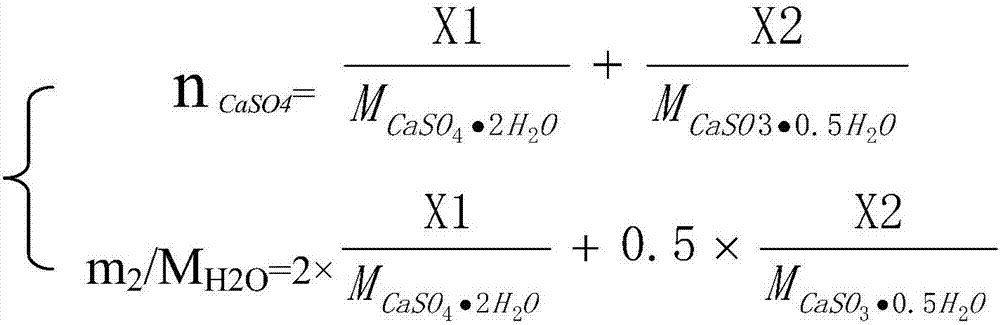

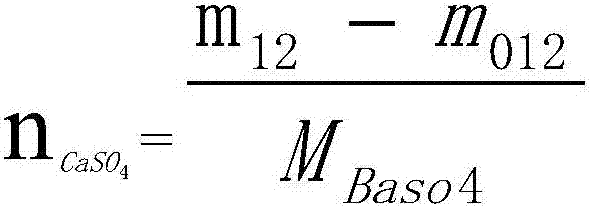

[0042] (2) Take off the glass fiber filter membrane in the smoke sampling gun, weigh the original mass m of the gypsum sample intercepted on the glass fiber filter membrane 0 , and then dry the moisture contained in it at 230°C±5°C to obtain the mass m of the dried sample 1 ; Next, using the formula m 2 =m 1 -m 0 Calculate the total water of crystallization content m in this gypsum sample 2 , CaSO 3 0.5H 2 O, CaSO 4 2H...

Embodiment 2

[0057] Such as figure 1 As shown, a method for detecting the content of gypsum particles in the desulfurization outlet flue gas of the present embodiment includes the following steps:

[0058] (1) Use at least two heatable smoke sampling guns with built-in glass fiber filter membranes (use temperature is 105°C) to take 2000L volume of flue gas from the same measuring hole at the desulfurization outlet; 0.24μm glass fiber filter membrane, made of silica, does not contain calcium ions and sulfate ions;

[0059] (2) Take off the glass fiber filter membrane in the smoke sampling gun, weigh the original mass m of the gypsum sample intercepted on the glass fiber filter membrane 0 , and then dry the moisture contained in it at 230°C±5°C to obtain the mass m of the dried sample 1 ; Next, using the formula m 2 =m 1 -m 0 Calculate the total water of crystallization content m in this gypsum sample 2 , CaSO 3 0.5H 2 O, CaSO 4 2H 2 The sum of the mass of crystallization water car...

Embodiment 3

[0074] Such as figure 1 As shown, a method for detecting the content of gypsum particles in the desulfurization outlet flue gas of the present embodiment includes the following steps:

[0075] (1) Use at least two heatable smoke sampling guns with built-in glass fiber filter membranes (the operating temperature is 110°C) to take 5000L of flue gas in the same measuring hole at the desulfurization outlet; 0.24μm glass fiber filter membrane, made of silica, does not contain calcium ions and sulfate ions;

[0076] (2) Take off the glass fiber filter membrane in the smoke sampling gun, weigh the original mass m of the gypsum sample intercepted on the glass fiber filter membrane 0 , and then dry the moisture contained in it at 230°C±5°C to obtain the mass m of the dried sample 1 ; Next, using the formula m 2 =m 1 -m 0 Calculate the total water of crystallization content m in this gypsum sample 2 , CaSO 3 0.5H 2 O, CaSO 4 2H 2 The sum of the crystal water mass carried by O;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com