Compound feed used for polyculture of bighead silver carps and herrings and preparation method thereof

A technology of compound feed and silver carp and bighead carp, which is applied in the field of fish farming, can solve the problems such as the increase of bacteria in the water body and the increased disease probability of silver carp and bighead carp, and achieve the effects of avoiding nutrient waste, improving disease resistance and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

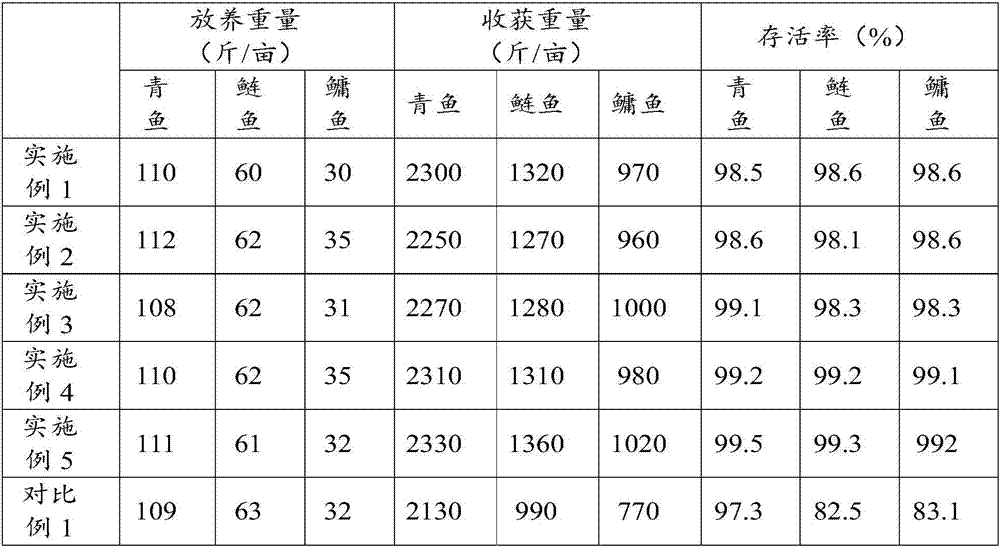

Examples

preparation example Construction

[0031] A method for preparing the above-mentioned compound feed for mixed culture of silver carp, bighead carp and herring comprises a sinking feed preparation step and a floating feed preparation step.

[0032] Among them, the sinking feed preparation steps include: 10-20 parts of fish meal, 10-20 parts of green shrimp powder, 10-20 parts of sweet potato powder, 5-10 parts of loach powder, 10-20 parts of silkworm chrysalis powder, 10-20 parts of bean cake powder 10-20 parts of snail powder, 1-2 parts of calcium dihydrogen phosphate, 1-5 parts of linolenic acid, 1-5 parts of linoleic acid, 0.5-1 part of vitamin premix, 0.5-1 part of amino acid premix , and 0.5 to 1 part of the mineral premix are mixed, crushed into powder, and granulated. Preferably, the raw materials are mixed and pulverized into powders of 10-50 meshes, and aged at 50-60°C. The aging temperature should not be too high to avoid vitamin damage. After aging, it is processed into columnar particles with a diame...

Embodiment 1

[0037] The invention provides a compound feed for mixed culture of silver carp, bighead carp and herring, which is prepared by mixing sinking feed and floating feed at a ratio of 1:1.

[0038] Wherein, the raw material of sinking feed is calculated in parts by weight, including: 10 parts of fish meal, 10 parts of green shrimp meal, 10 parts of sweet potato meal, 5 parts of loach meal, 10 parts of silkworm chrysalis meal, 10 parts of bean cake meal, 10 parts of snail meal, 1 part of calcium dihydrogen phosphate, 1 part of linolenic acid, 3 parts of linoleic acid, 0.5 part of vitamin premix, 0.5 part of amino acid premix, and 0.5 part of mineral premix.

[0039] The raw materials of the floating feed are counted in parts by weight, including: 5 parts of soybean meal, 5 parts of rapeseed meal, 5 parts of cotton meal, 3 parts of silkworm chrysalis powder, 1 part of linolenic acid, 1 part of linoleic acid, 2 parts of yeast powder, ginkgo 2 parts of leaves, 2 parts of Houttuynia cor...

Embodiment 2

[0045] The invention provides a compound feed for mixed culture of silver carp, bighead carp and herring, which is prepared by mixing sinking feed and floating feed at a ratio of 1:1.

[0046] Wherein, the raw material of sinking feed is calculated in parts by weight, including: 20 parts of fish meal, 20 parts of green shrimp meal, 20 parts of sweet potato meal, 10 parts of loach meal, 20 parts of silkworm chrysalis meal, 20 parts of bean cake meal, 10 parts of snail meal, 2 parts of calcium dihydrogen phosphate, 5 parts of linolenic acid, 1 part of linoleic acid, 1 part of vitamin premix, 0.5 part of amino acid premix, and 0.5 part of mineral premix.

[0047] The raw materials of the floating feed are calculated in parts by weight, including: 10 parts of soybean meal, 10 parts of rapeseed meal, 10 parts of cotton meal, 8 parts of silkworm chrysalis powder, 1 part of linolenic acid, 1 part of linoleic acid, 2 parts of yeast powder, ginkgo 2 parts of leaves, 2 parts of Houttuyn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com