Device and method for recycling spray cooling cutting fluid

A technology of spray cooling and cutting fluid, applied in metal processing equipment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of manpower and material resources, increased processing costs, waste of resources, etc. achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

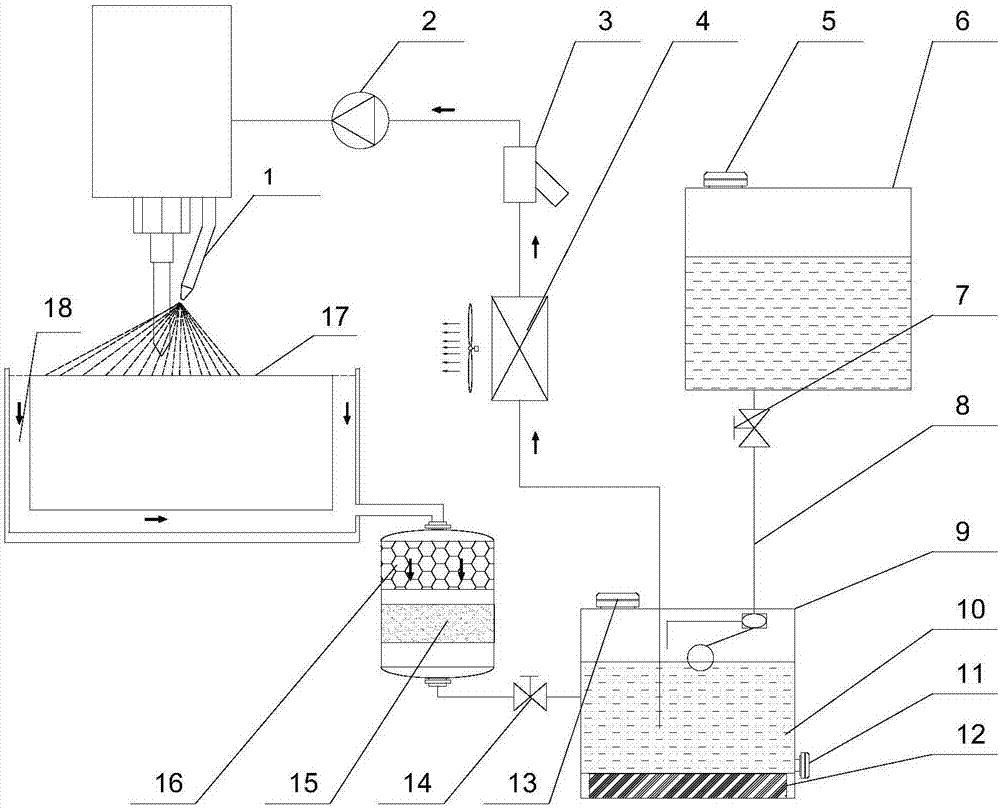

[0011] Such as figure 1 As shown, a kind of equipment and method for recycling working fluid of the present invention comprises an atomizing nozzle (1), a high-pressure water pump (2), a Y-type filter (3), an air-cooled cooler (4), and a liquid replenishing Port (5), replenishment tank (6), stop valve 1 (7), float valve (8), liquid storage tank (9), recovery fluid (10), sewage outlet (11), magnet (12), cleaning port (13), cut-off valve 2 (14), secondary filter (15), primary filter (16), stand (17), cutting fluid recovery channel (18) forms.

[0012] The specific implementation process is:

[0013] When the system starts to work, the cutting fluid is pumped out from the liquid storage tank (9) by the high-pressure water pump (2). The cutting fluid first passes through the air-cooled cooler (4) to cool down, and then passes through the Y-type filter (3) to remove impurities. Filter, and then flow to the atomizing nozzle (1) through the pressurized pressure of the high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com