A kind of purification method of anhydrous hydrofluoric acid

A technology of anhydrous hydrofluoric acid and a purification method, which is applied in the field of preparation of anhydrous hydrofluoric acid, can solve the problems of large energy consumption, large load of rectification tower, and large energy consumption, so as to reduce load, ensure product quality, and avoid The effect of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

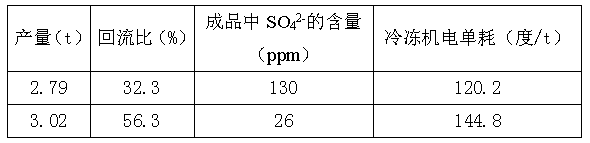

Embodiment 1

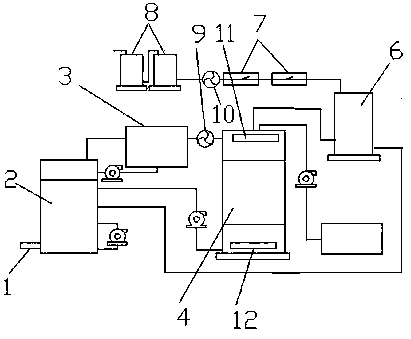

[0028] Such as figure 1 The purification device of a kind of anhydrous hydrofluoric acid shown comprises the washing tower 2, primary condenser 3 and purification tower 4 connected successively by gas phase pipeline, and described washing tower 2 is connected with crude hydrogen fluoride gas guide pipe 1; A primary fan 9 is connected between the primary condenser 3 and the purification tower 4; the top exhaust port of the purification tower 4 is connected to the sulfuric acid absorption tower 6, and the purification tower 4 is provided with a return pipe; the washing tower 2 is from top to bottom A plurality of acid inlets connected with the acid discharge port of the primary condenser, the acid discharge port of the purification tower, and the acid discharge port of the sulfuric acid absorption tower are successively arranged, and the washing acid circulation inlet of the washing tower 2 is arranged at the lower part of the acid inlet; the purification tower 4 top is provided...

Embodiment 2

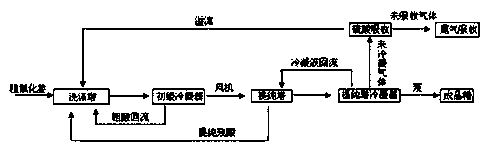

[0030] Such as figure 2 Shown, a kind of purification method of anhydrous hydrofluoric acid is carried out in the purification device of embodiment 1, and concrete operation comprises the following steps:

[0031] 1. Scrubber washing

[0032] Under the action of the first-stage fan, the crude hydrogen fluoride gas generated in the reaction furnace enters the washing tower through the air duct. The packing in the washing tower is Φ50×60 polytetrafluoroethylene Raschig ring, the height is 20m, and the washing acid is from top to bottom They are: the crude acid returned by the primary condenser, the residual acid returned by the purification tower, the overflow sulfuric acid returned by the sulfuric acid absorption tower, and the mixed acid of the washing tower.

[0033] 2. Primary condensation

[0034] The washed hydrogen fluoride gas enters the primary condenser, the temperature of the condensed water is -2°C, and the condensation volume is controlled at 40%. The condensate ...

Embodiment 3

[0040] Such as figure 2 Shown, a kind of purification method of anhydrous hydrofluoric acid is carried out in the purification device of embodiment 1, and concrete operation comprises the following steps:

[0041] 1. Scrubber washing

[0042] Under the action of the first-stage fan, the crude hydrogen fluoride gas generated in the reaction furnace enters the washing tower through the air duct. The packing in the washing tower is Φ50×60 polytetrafluoroethylene Raschig ring, the height is 20m, and the washing acid is from top to bottom They are: the crude acid returned by the primary condenser, the residual acid returned by the purification tower, the overflow sulfuric acid returned by the sulfuric acid absorption tower, and the mixed acid of the washing tower.

[0043] 2. Primary condensation

[0044] The washed hydrogen fluoride gas enters the primary condenser, the temperature of the condensed water is -2°C, and the condensation volume is controlled at 50%. The condensate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com