An open "click-radical" one-pot approach using copper thioxanthone carboxylate as photocatalyst and oxygen scavenger

A technology of copper thioxanthone carboxylate and copper xanthone carboxylate is applied in the open "click-radical field" to achieve the effect of saving energy and simplifying the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

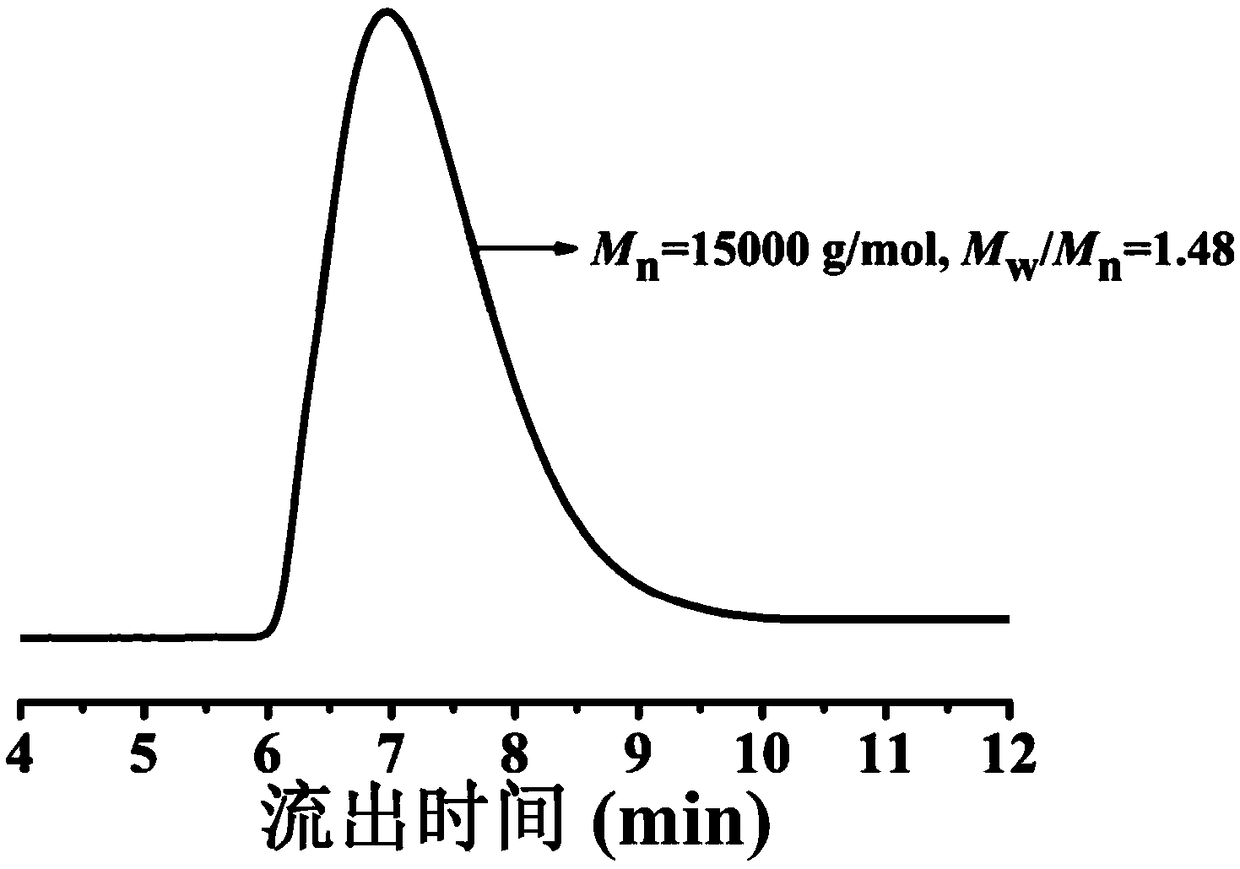

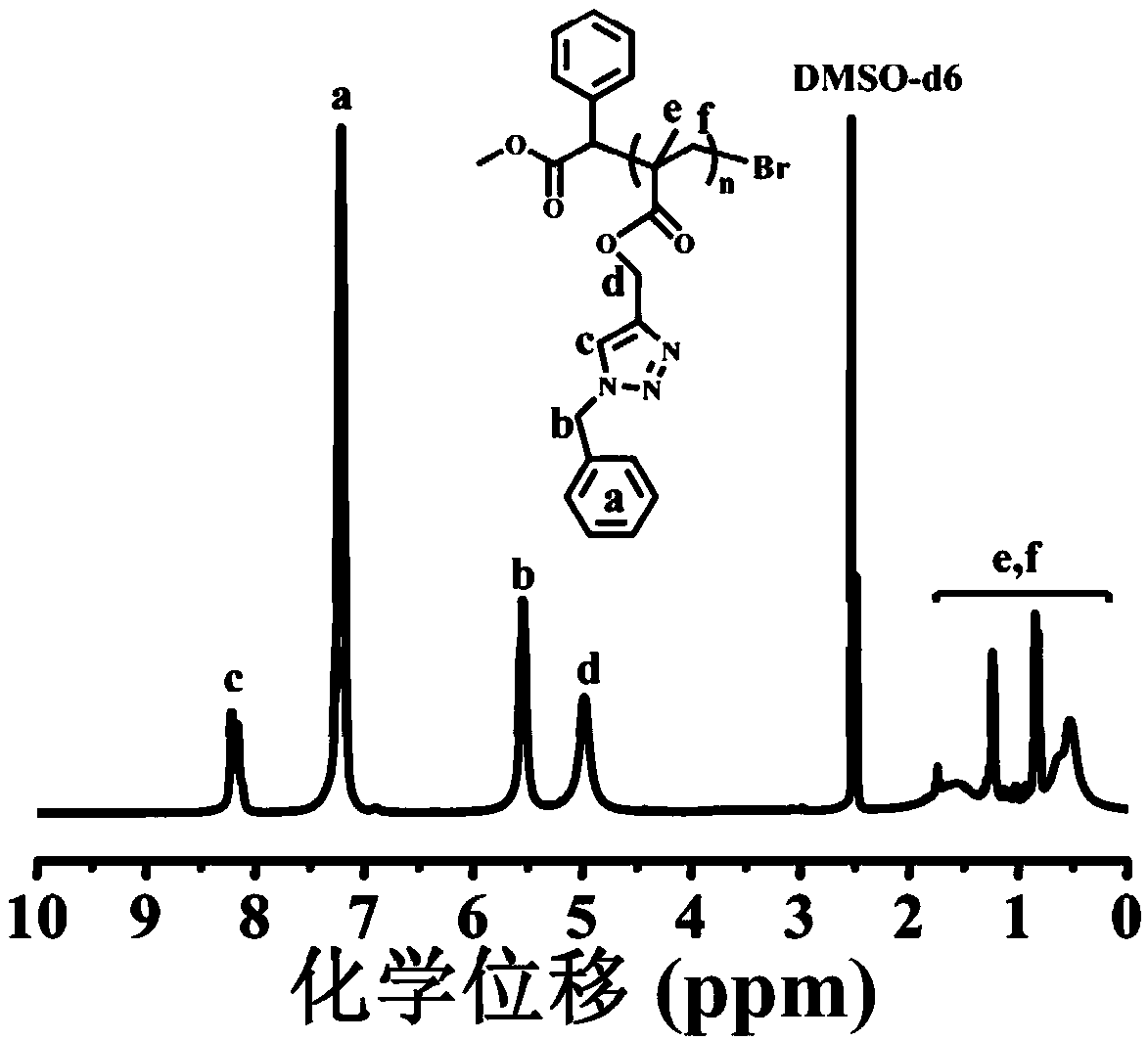

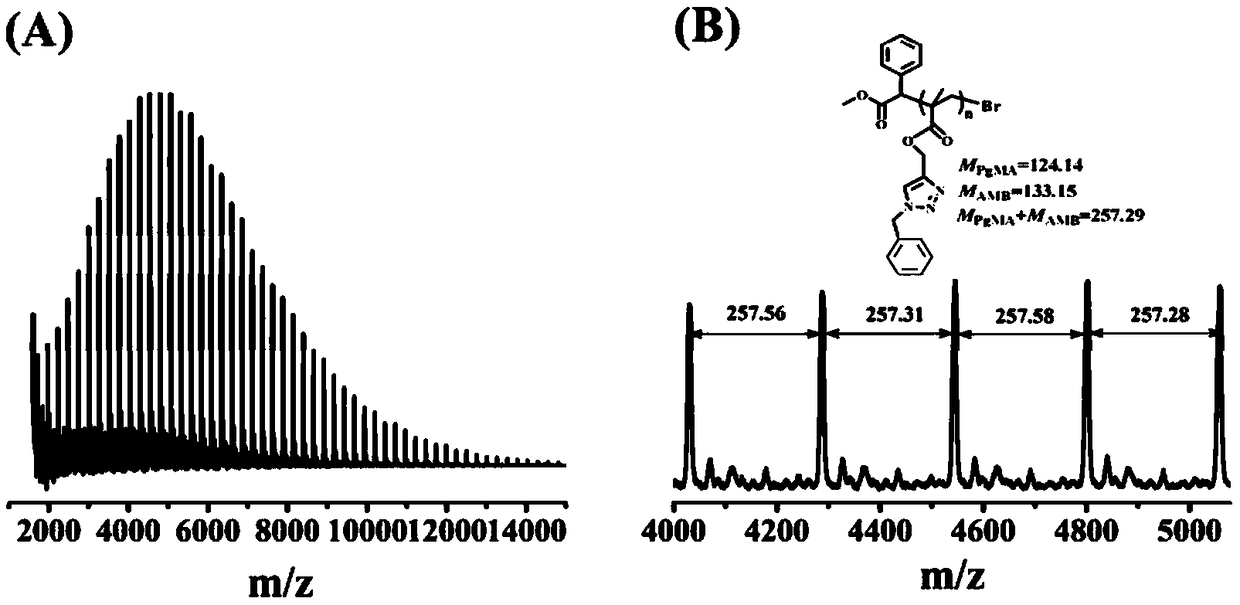

Embodiment 1

[0039] Weigh 0.79mmol of propynyl methacrylate, 0.79mmol of benzyl azide, 0.24mmol of copper thioxanthone carboxylate and 0.079mmol of methyl 2-bromo-2-phenylacetate required for polymerization with an electronic balance , into a 5ml ampere tube, add 0.4mL dimethyl sulfoxide, mix evenly, and place the open ampere tube under sunlight for 18 hours to react. After the polymerization, tetrahydrofuran was added into the ammeter tube to dilute the polymer, and precipitated in methanol, filtered by suction, and dried to obtain 0.179g of solid powder.

[0040] The light control experiment steps are as follows: use an electronic balance to weigh 0.79 mol of propynyl methacrylate, 0.79 mol of benzyl azide, 0.24 mol of copper thioxanthone carboxylate and 0.079 mmol of 2-bromo-2 - Methyl phenylacetate, add in the NMR tube, add 0.4mL deuterated dimethyl sulfoxide, after mixing, the NMR spectrum at the beginning of the test. After irradiating for 30 minutes, NMR was measured, and then oxyg...

Embodiment 2

[0042]Weigh 0.79mmol of propynyl methacrylate, 0.79mmol of benzyl azide, 0.024mmol of copper thioxanthone carboxylate and 0.0079mmol of methyl 2-bromo-2-phenylacetate required for polymerization with an electronic balance , into a 5ml ampere tube, add 0.4mL dimethyl sulfoxide, mix evenly, and place the open ampere tube under sunlight for 17h. After the polymerization, tetrahydrofuran was added into the ampere tube to dilute the polymer, and precipitated in methanol, suction filtered, and dried to obtain 0.175g of solid powder.

[0043] The light control experiment steps are as follows: use an electronic balance to weigh 0.79 mol of propynyl methacrylate, 0.79 mol of benzyl azide, 0.024 mol of copper thioxanthone carboxylate and 0.0079 mmol of 2-bromo-2 - Methyl phenylacetate, add in the NMR tube, add 0.4mL deuterated dimethyl sulfoxide, after mixing, the NMR spectrum at the beginning of the test. After irradiating for 30 minutes, NMR was measured, and then oxygen was injected...

Embodiment 3

[0045] Weigh 0.79mmol of propynyl methacrylate, 0.79mmol of benzyl azide, 0.0024mmol of copper thioxanthone carboxylate and 0.00079mmol of methyl 2-bromo-2-phenylacetate required for polymerization with an electronic balance , into a 20ml ampere tube, add 0.4mL dimethyl sulfoxide, mix well, and place the open ampere tube under sunlight for 16h. After the polymerization, tetrahydrofuran was added into the ampere tube to dilute the polymer, and precipitated in methanol, suction filtered, and dried to obtain 0.172g of solid powder.

[0046] The light control experiment steps are as follows: use an electronic balance to weigh 0.79 mol of propynyl methacrylate, 0.79 mol of benzyl azide, 0.0024 mol of copper thioxanthone carboxylate and 0.00079 mmol of 2-bromo-2 - Methyl phenylacetate, add in the NMR tube, add 0.4mL deuterated dimethyl sulfoxide, after mixing, the NMR spectrum at the beginning of the test. After irradiating for 30 minutes, NMR was measured, and then oxygen was inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com