Method for preparing liquid fuel with gamma-valerolactone

A technology of liquid fuel and valerolactone, which is applied in the preparation of liquid hydrocarbon mixture, the control/regulation of distillation of biological raw materials and hydrocarbon oil, etc., can solve problems such as harsh reaction conditions, and achieve simple reaction process, convenient operation, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

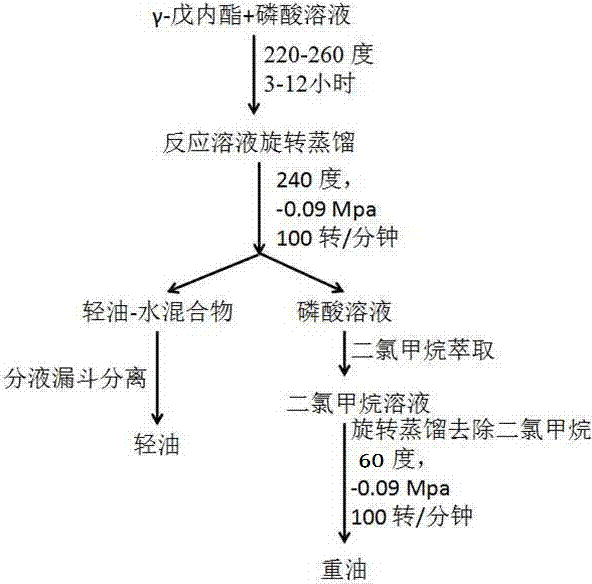

[0026] In this embodiment, the specific steps of preparing liquid fuels by using phosphoric acid to catalyze the conversion of poly-3-hydroxybutyrate are as follows (for the flow chart, see figure 1 ):

[0027] (1) Take 15 g of γ-valerolactone and 60 mL of phosphoric acid solution (112.2 g) into a 100 mL p-polyphenyl reaction tank. The temperature was raised to 240 °C at a rate of 5 °C / min, and kept at a constant temperature of 240 °C for 6 h. After the reaction was completed, it was rapidly cooled to room temperature with cold water. It was found that the γ-valerolactone was basically completely converted by high-performance liquid chromatography, and the γ-valerolactone 49% of the oxygen in the lactone is removed as carbon dioxide, and part of the oxygen is removed as water and carbon monoxide;

[0028] (2) The product after the reaction in the step (1) was rotary evaporated at 240 °C and -0.09 Mpa to obtain an oil-water mixture and a phosphoric acid mixture, and the oil-wa...

Embodiment 2

[0036] Take 15 g of γ-valerolactone and 15 mL of phosphoric acid solution (28 g) into a 100 mL p-polyphenylene reaction tank. The temperature was raised to 260 °C by program, and kept at a constant temperature of 260 °C for 6 h. After the reaction was completed, it was cooled to room temperature, and light oil was obtained by rotary evaporation, and heavy oil was obtained by extraction and distillation with dichloromethane.

Embodiment 3

[0038] Take 1 g of γ-valerolactone and 50 mL of phosphoric acid solution (93.7 g) into a 100 mL p-polyphenylene reaction tank. The temperature was raised to 220 °C at a rate of 8 °C / min, and kept at a constant temperature of 220 °C for 12 h. After the reaction was completed, it was cooled to room temperature, and light oil was obtained by rotary evaporation, and heavy oil was obtained by extraction and distillation with dichloromethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com