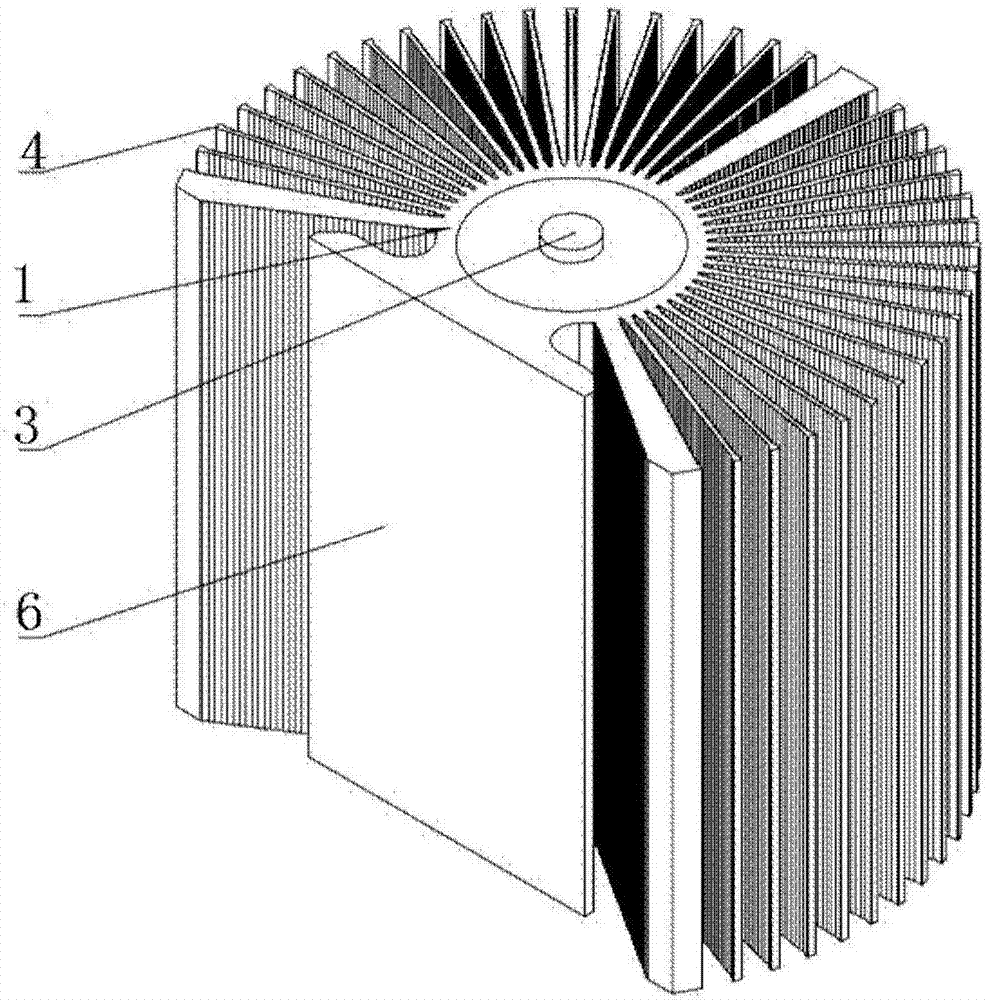

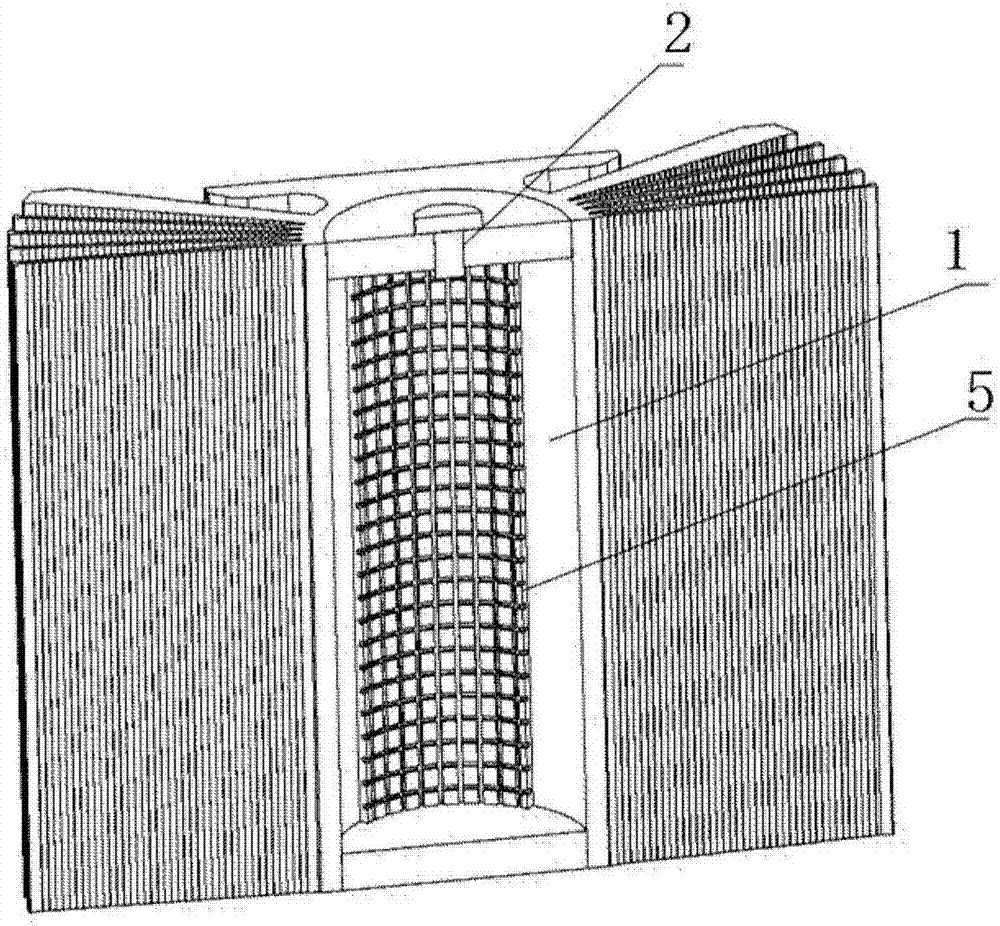

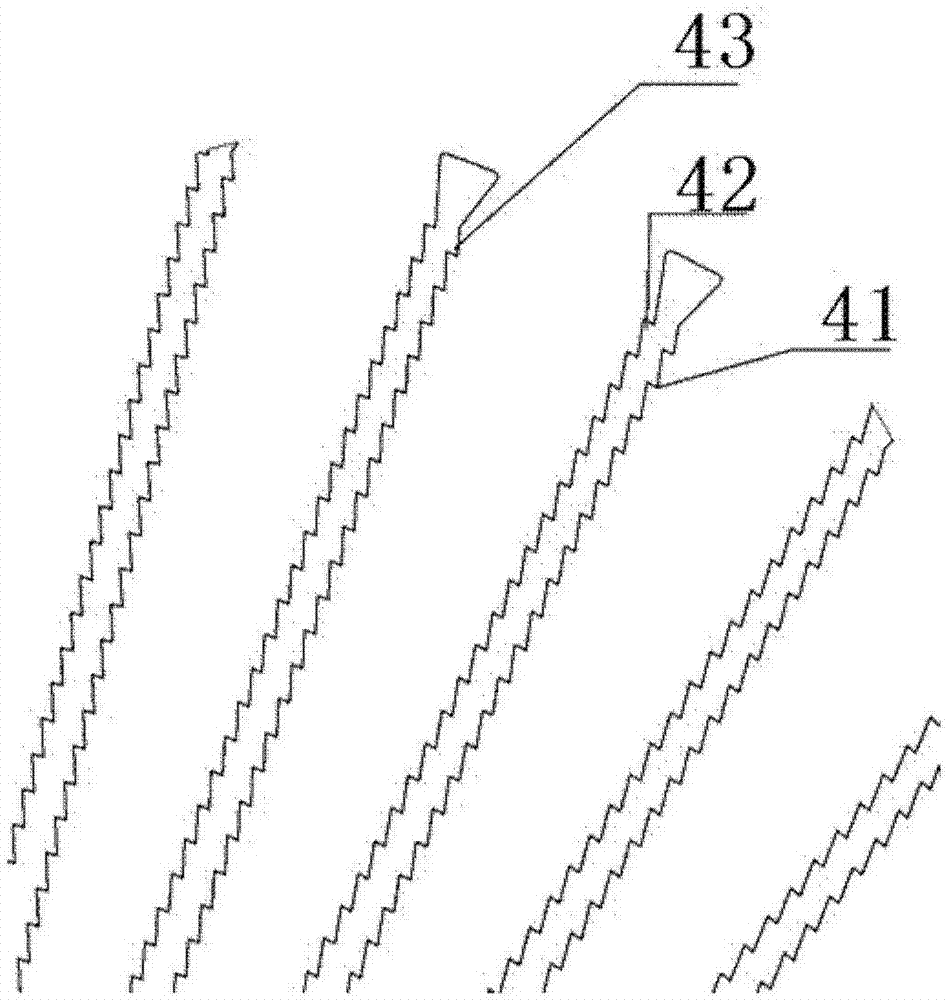

LED radiator

A technology of LED radiator and phase change heat conduction, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. rate reduction and other issues, to achieve the effects of light weight, low overall thermal resistance, and reduced contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the prior art, when the metal radiator conducts heat, a temperature gradient will be generated with the distance from the LED, and the temperature will be uneven. In order to solve this problem and achieve a certain amount of heat transfer, it is necessary to increase the heat transfer area to compensate. In addition, most LED radiators avoid forced convection, and use natural convection with no maintenance, high reliability and no power consumption. However, the disadvantage of natural convection is that the convective heat transfer coefficient is low. In order to achieve a certain amount of heat transfer, a larger heat transfer area is required. Therefore, in the prior art, it is commonly used to solve the above technical problems by increasing the heat exchange area, but this will cause the problems of increased cost, increased weight and reduced space utilization of LED lamps.

[0033] In order to solve the above-mentioned technical problems, the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com