Pixel structure and preparation method thereof and display device

A pixel structure and pixel technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reducing product yield, limitation, high resolution and maximum pixel aperture ratio, and it is difficult to achieve the best of both worlds, reducing the number of openings, Reduce the difficulty of production and display the effect of good chromaticity uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a pixel structure, which is formed by using FMM for the pixel structure of AMOLED. Due to the bottleneck of FMM in the manufacturing process, OLED display devices have defects such as color mixing. By changing the shape and arrangement of sub-pixels (Arrangement of RGB pixel), high-resolution products can be prepared without making a huge number of openings on the metal mask, which makes the chromaticity uniformity of the display device better.

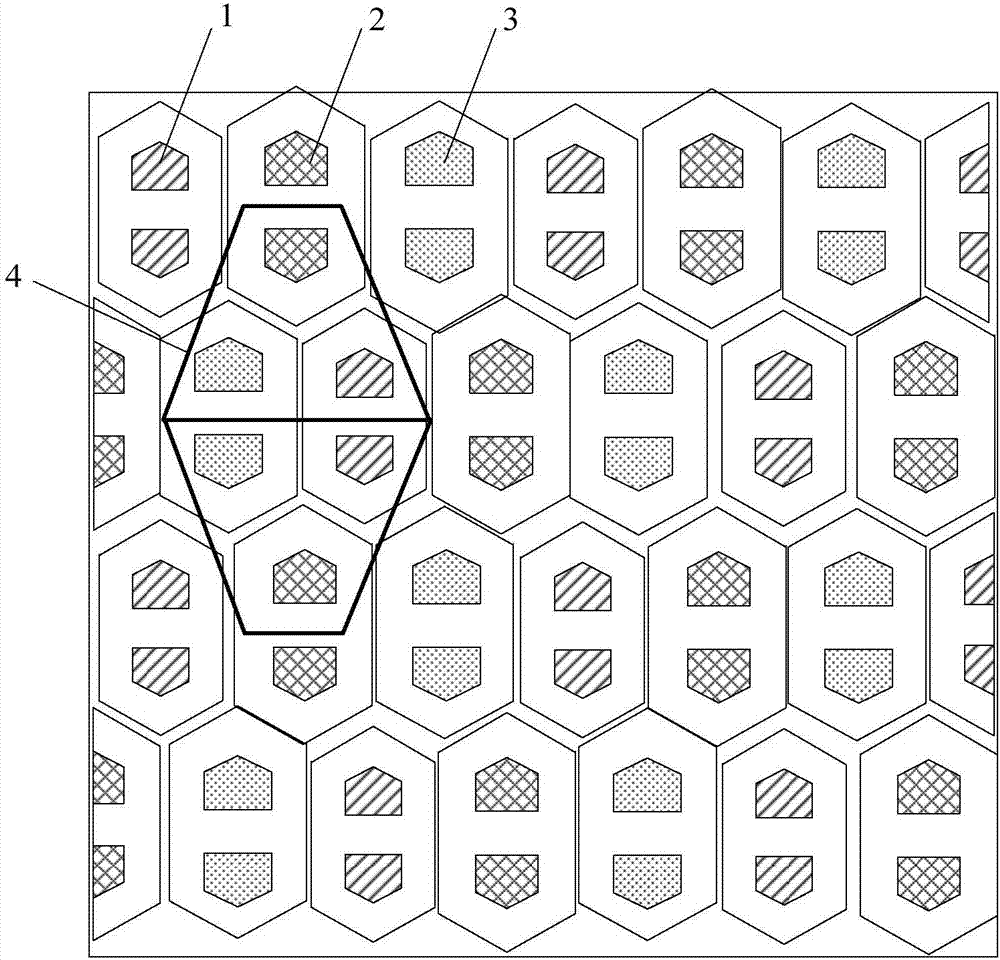

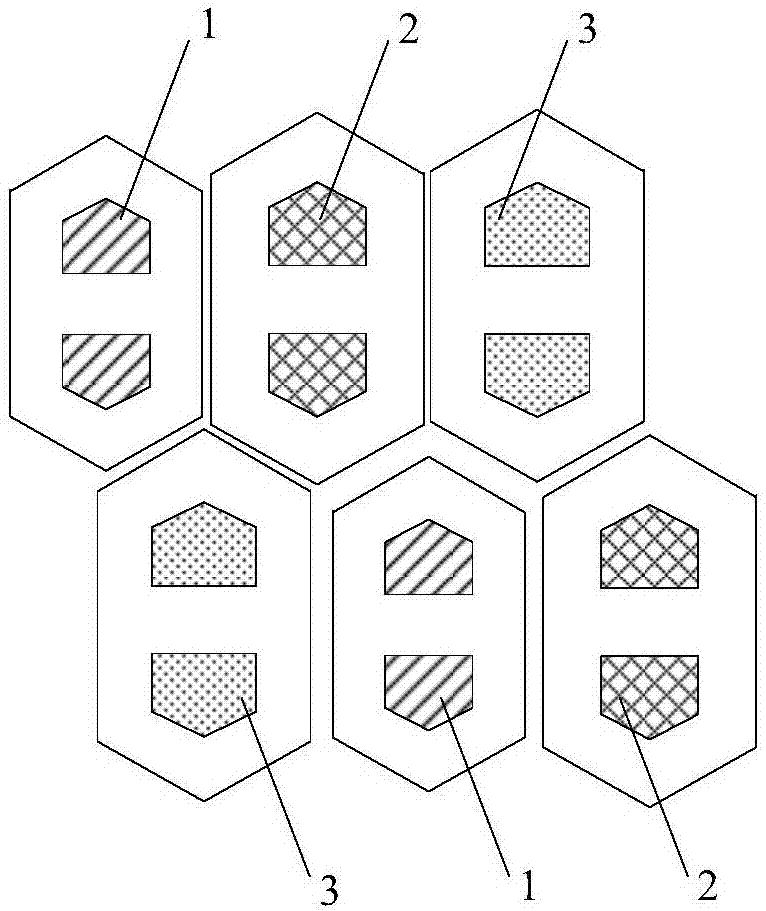

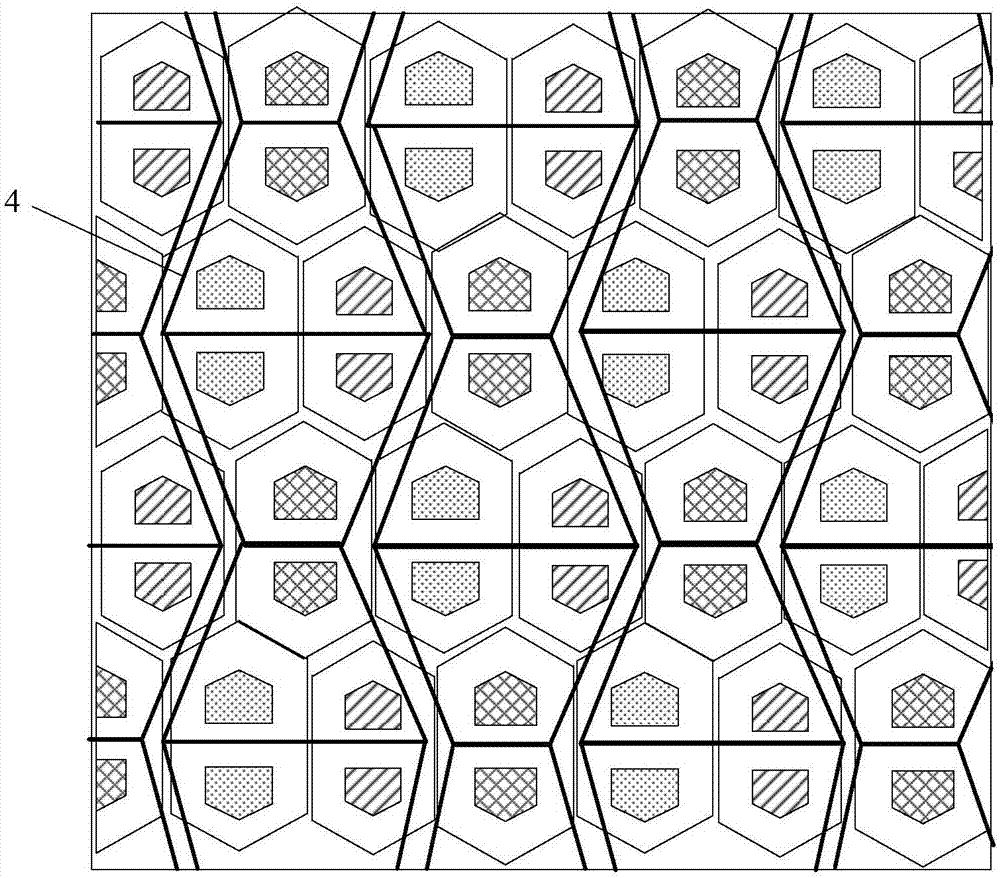

[0035] Such as figure 1 As shown, the pixel structure includes a first sub-pixel 1, a second sub-pixel 2 and a third sub-pixel 3, wherein the first sub-pixel 1, the second sub-pixel 2 and the third sub-pixel 3 are arranged circularly in sequence in the row direction , the same sub-pixels in every two adjacent rows are arranged at intervals in the column direction, and the same sub-pixels in adjacent rows are mirror-symmetrically arranged in the column direction; the second sub-pixel 2 is located in a su...

Embodiment 2

[0057] This embodiment provides a display device, which includes the pixel structure in Embodiment 1.

[0058] The display device can be any product or component with a display function such as electronic paper, OLED panel, mobile phone, tablet computer, television, monitor, notebook computer, digital photo frame, navigator, etc.

[0059] In the display device, since the pixel structure has a better vapor deposition process, it has a higher yield rate and a better display effect.

[0060] The present invention provides a new type of pixel structure. By optimizing the arrangement of RGB sub-pixels, the pixel structure can achieve higher resolution under the same FMM process precision, and improve the aperture ratio of the pixel, which solves the problem of the organic pixel in the prior art. Due to the problem that the resolution of light-emitting display devices is difficult to improve due to process reasons, it has achieved great advantages between high-resolution and high-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com