Handheld laser cleaning machine and control method

A laser cleaning, hand-held technology, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems affecting work efficiency, prone to safety accidents, inflexibility, etc., to avoid safety Accidents, high-speed effective removal, and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiments and drawings.

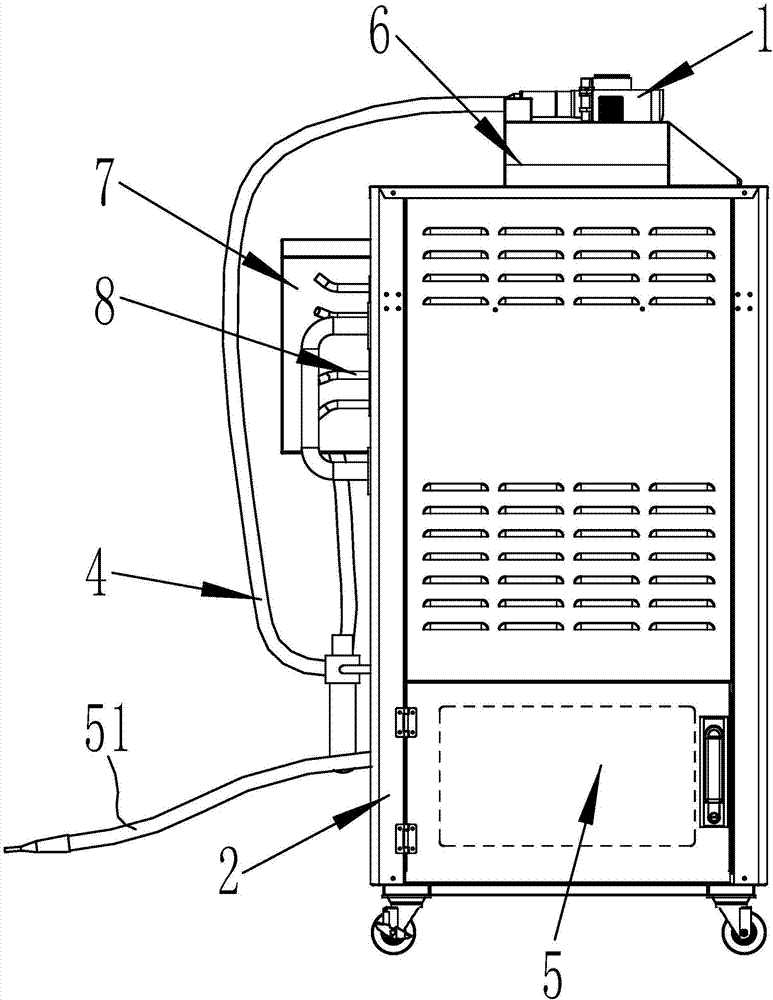

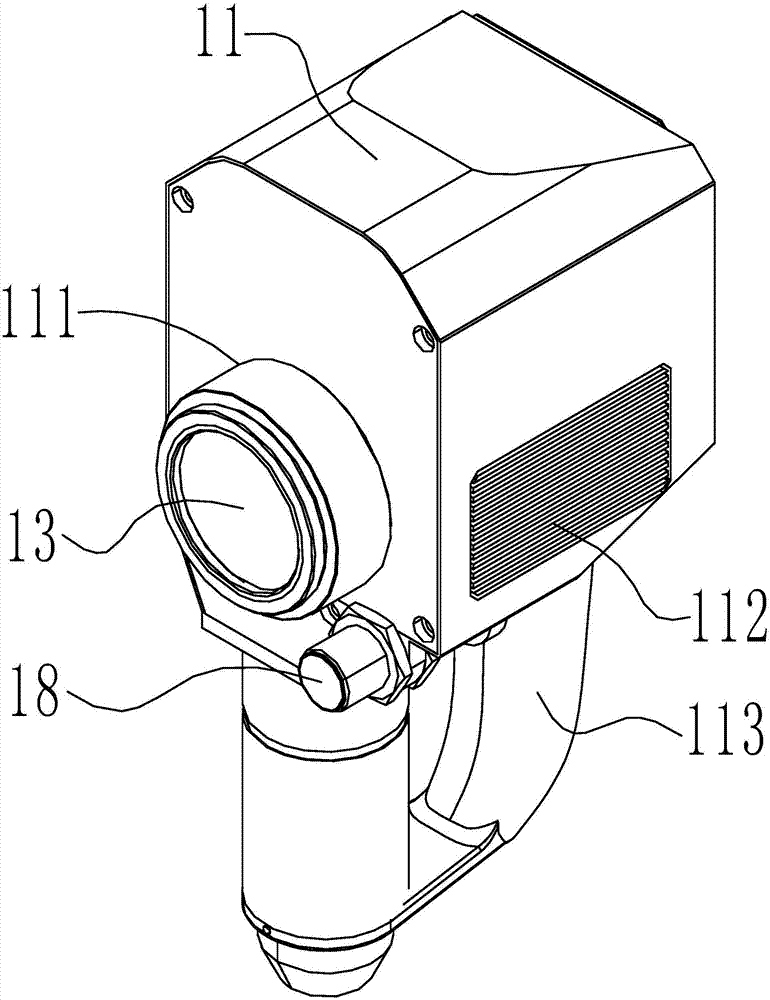

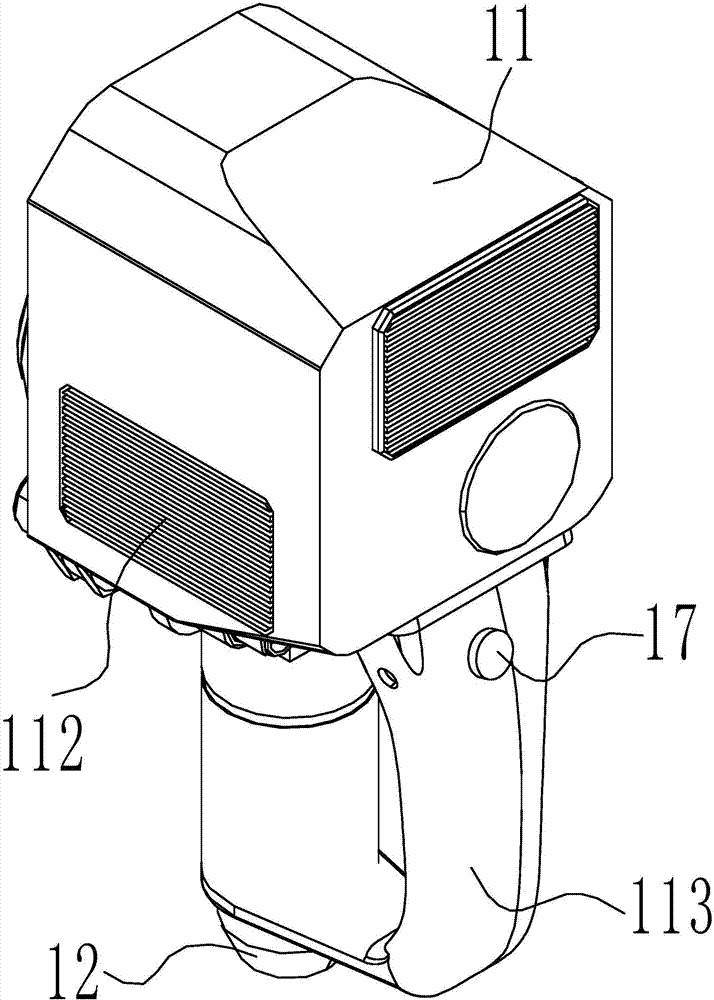

[0035] Such as figure 1 , Image 6 with Figure 7 As shown, a hand-held laser cleaning machine includes a laser emitting gun 1 and a mobile cabinet 2. A laser 3 and a vacuum cleaner 5 are provided in the mobile cabinet 2, and the laser 3 and the laser emitting gun 1 are connected by a wire harness 4. The wire harness 4 includes optical fibers, wires, data transmission lines, and the like. The outer wall of the mobile cabinet 2 is provided with a junction box 7 and a winding reel 8. The two ends of the wiring harness 4 are respectively connected to the junction box 7 and the junction pipe 12, and the wiring harness 4 can be wound on the winding reel. 8, play the role of regularizing the wiring harness 4. The outer wall of the mobile cabinet 2 has an air outlet 25 and a duct opening 26. The air outlet 25 is used to discharge the wind generated by the vacuum cleaner 5. The d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap