Polyvinylidene fluoride composite oriented dielectric film with high beta-crystal content and preparation method of dielectric film

A technology of polyvinylidene fluoride and crystal content, applied in high β-phase polyvinylidene fluoride oriented film, polyvinylidene fluoride composite oriented dielectric film with high β crystal content and its preparation, can solve the problem of low β-phase crystal content of PVDF film , unfavorable standardized production and industrial application, etc., to achieve a wide range of market application prospects, simple preparation methods and process flow, and the effect of increased dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

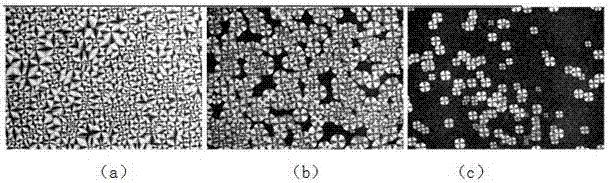

Image

Examples

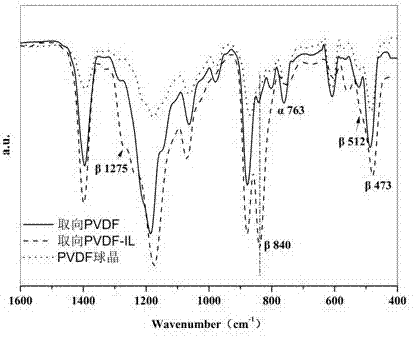

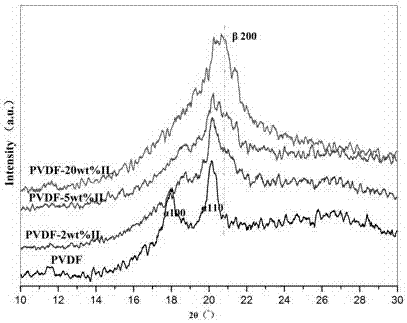

Embodiment 1

[0025] A polyvinylidene fluoride composite oriented dielectric film with a hydrophilic and high β crystal content, composed of polyvinylidene fluoride and an ionic liquid with a mass ratio of 100:1 by mass percentage; the concentration of polyvinylidene fluoride solution is 1wt% %; The thickness of the polyvinylidene fluoride oriented film is not more than 30 μm; the drawing rate of the uniaxial stretching is 2 cm / s, and the temperature of the constant temperature heating table is 140 ° C when the uniaxial stretching is applied.

Embodiment 2

[0027] A polyvinylidene fluoride composite oriented dielectric film with a hydrophilic and high β crystal content, composed of polyvinylidene fluoride and an ionic liquid with a mass ratio of 100:20 by mass percentage; the concentration of polyvinylidene fluoride solution is 10wt% ; The thickness of the polyvinylidene fluoride oriented film is not more than 25 μm; the drawing rate of the uniaxial stretching is 4 cm / s, and the temperature of the constant temperature heating stage is 150 ° C when the uniaxial stretching is applied.

Embodiment 3

[0029] A polyvinylidene fluoride composite oriented dielectric film with a hydrophilic and high β crystal content, composed of polyvinylidene fluoride and an ionic liquid with a mass ratio of 100:30 by mass percentage; the concentration of polyvinylidene fluoride solution is 20wt% ; The thickness of the polyvinylidene fluoride oriented film is not more than 29 μm; the drawing rate of the uniaxial stretching is 5 cm / s, and the temperature of the constant temperature heating stage is 160 ° C when the uniaxial stretching is applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com