Waterborne adhesive for anodized aluminum as well as preparation method and use method of waterborne adhesive

An anodized aluminum, water-based technology, applied in the field of anodized aluminum hot stamping, can solve problems such as difficult to balance performance, poor adhesion, narrow range, etc., achieve wide heat resistance and water resistance, expand the hot stamping temperature range, and bond power-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

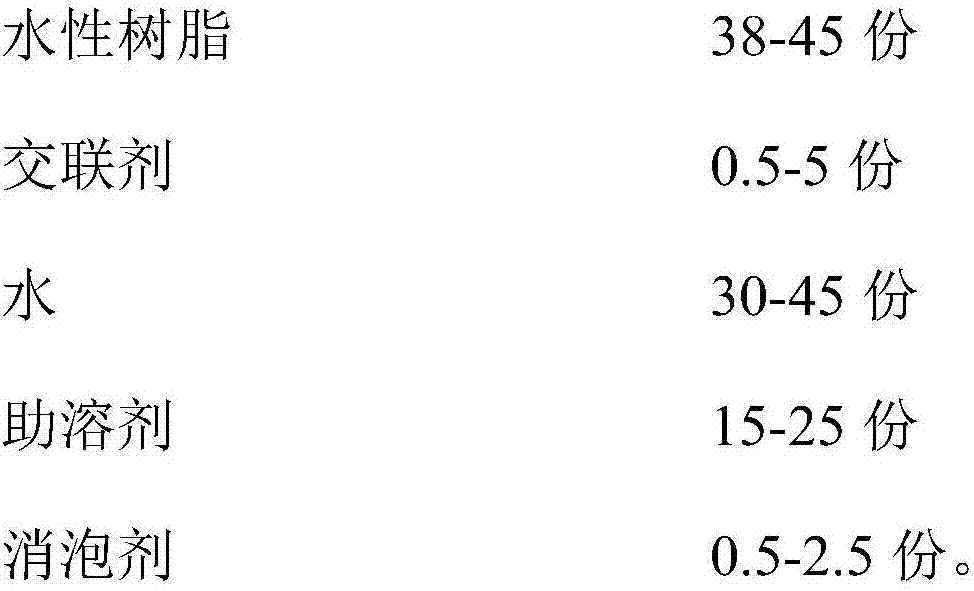

[0043] A water-based adhesive for anodized aluminum, comprising the following components in parts by weight:

[0044]

[0045] Wherein, the water-based resin is composed of water-based acrylic modified polyurethane resin and water-based acrylic resin in a mass ratio of 1:1.

[0046] The preparation method of the above-mentioned anodized aluminum water-based adhesive comprises the following steps:

[0047] (1) Stir and mix the water-based resin and deionized water in the formulated amount at 10°C at a speed of 300r / min;

[0048] (2) join the ethanol of formula quantity in the solution that step (1) obtains, stir and mix under the rotating speed of 300r / min;

[0049] (3) Add the blocked polyisocyanate of formula quantity in the solution that step (2) obtains, stir and mix under the rotating speed of 300r / min;

[0050] (4) Add the formulated amount of polyether defoamer to the solution obtained in step (3), stir and mix at a speed of 300 r / min until no bubbles are generated,...

Embodiment 2

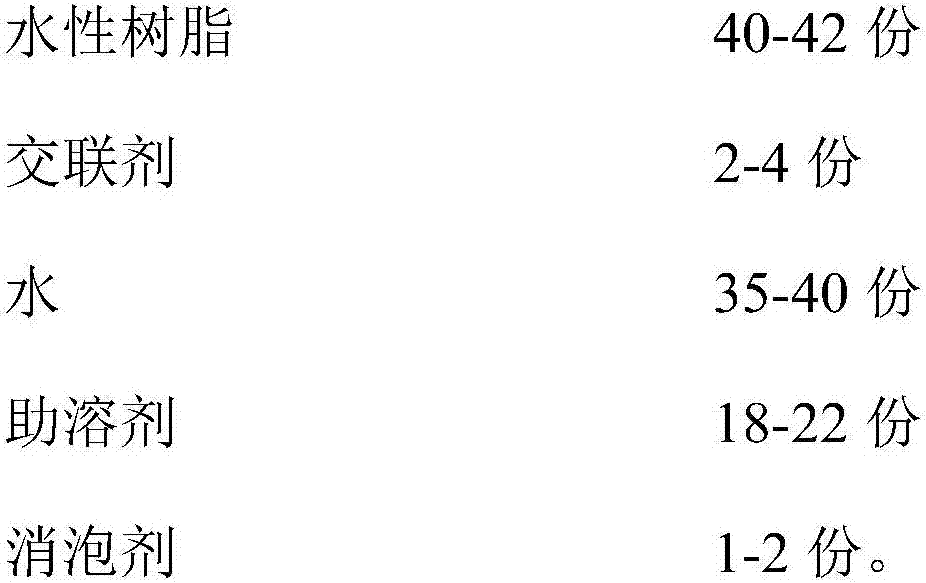

[0053] A water-based adhesive for anodized aluminum, comprising the following components in parts by weight:

[0054]

[0055] Among them, the water-based resin is composed of water-based acrylic resin and water-based saturated polyester resin in a mass ratio of 1:2.

[0056] The preparation method of the above-mentioned anodized aluminum water-based adhesive comprises the following steps:

[0057] (1) Stir and mix the water-based resin and deionized water in the formulated amount at 30°C at a speed of 100r / min;

[0058] (2) The isopropanol of formula quantity is joined in the solution that step (1) obtains, stir and mix under the rotating speed of 100r / min;

[0059] (3) Add the amino resin of formula quantity in the solution that step (2) obtains, stir and mix under the rotating speed of 100r / min;

[0060] (4) Add the formulated amount of high-carbon alcohol defoamer into the solution obtained in step (3), and stir and mix at a speed of 100 r / min until no bubbles are gen...

Embodiment 3

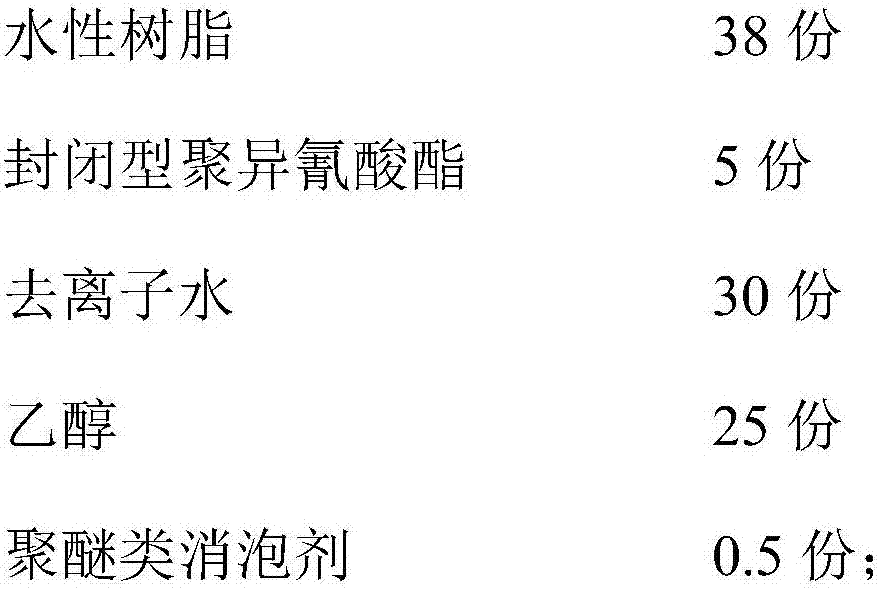

[0063] A water-based adhesive for anodized aluminum, comprising the following components in parts by weight:

[0064]

[0065] Wherein, the water-based resin is composed of water-based acrylic modified polyurethane resin and water-based terpene resin in a mass ratio of 1:3.

[0066] The preparation method of the above-mentioned anodized aluminum water-based adhesive comprises the following steps:

[0067] (1) Stir and mix the water-based resin and deionized water of the formulated amount at 20°C at a speed of 200r / min;

[0068] (2) Add the propylene glycol methyl ether of formula quantity in the solution that step (1) obtains, stir and mix under the rotating speed of 200r / min;

[0069] (3) Add the aluminum acetylacetonate of formula quantity in the solution that step (2) obtains, stir and mix under the rotating speed of 200r / min;

[0070] (4) Add the formulated amount of n-octanol into the solution obtained in step (3), and stir and mix at a rotational speed of 200 r / min ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap