Low-temperature-resistant lithium-ion battery long in service life

A lithium-ion battery, low-temperature-resistant technology, applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of poor charge and discharge performance, short cycle life, low energy density, etc., to achieve high and low temperature cycle performance, Excellent performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

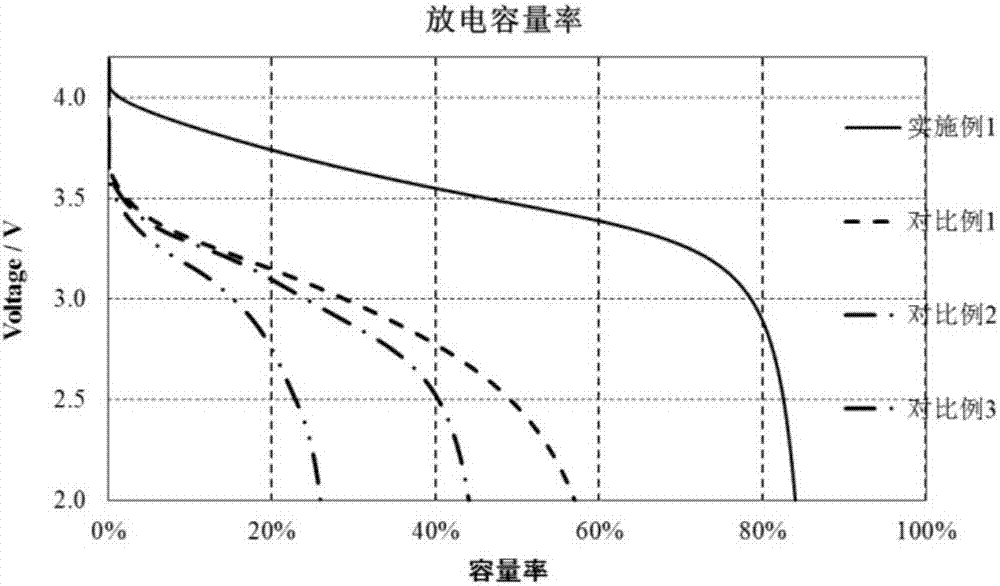

Embodiment 1

[0027] Example 1: LiNi with D50 of 8 μm is selected 0.5 co 0.2 mn 0.3 o 3 (hereinafter referred to as NCM523) as the cathode material. First mix the positive electrode material NCM523 and the conductive agent acetylene black (hereinafter referred to as HS-100), then add the binder PVDF and the solvent N-methylpyrrolidone (hereinafter referred to as NMP), and stir to prepare the positive electrode slurry. The distribution ratio of positive electrode material, conductive agent and binder is in accordance with NCM523:HS-100:PVDF=95:3:2. The slurry is coated, rolled, cut and dried to obtain a positive electrode sheet.

[0028] Modified natural graphite was selected as the negative electrode material. First mix natural graphite C, conductive agent carbon black (hereinafter referred to as SPC), and carboxymethyl cellulose (hereinafter referred to as CMC), then add solvent water and styrene-butadiene rubber (hereinafter referred to as SBR), and stir to prepare negative electrode...

Embodiment 2

[0030] Example 2: NCM523 with a D50 of 8 μm is selected as the positive electrode material. First mix the positive electrode material NCM523 and the conductive agent HS-100, then add the binder PVDF and the solvent NMP, and stir to prepare the positive electrode slurry. The distribution ratio of each component is in accordance with NCM523:HS-100:PVDF=94:3:3. The slurry is coated, rolled, cut and dried to obtain a positive electrode sheet.

[0031] Modified natural graphite was selected as the negative electrode material. First mix natural graphite C, conductive agent SPC, and CMC, then add solvent water and SBR, and stir to prepare negative electrode slurry. The distribution ratio of each component is in accordance with C:SPC:CMC:SBR=95:2:1:2. The slurry is coated, rolled, cut and dried to obtain a negative electrode sheet.

[0032] The positive electrode sheet, the negative electrode sheet, and the diaphragm are wound and hot pressed to obtain a core. The battery is inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com