Fiber-enhanced aerogel-metal composite material and preparation method thereof

A technology of metal composite materials and composite materials, which is applied in the field of preparation of metal matrix composite materials, can solve the problems of high brittleness, limitation, low resistance to mechanical shock and thermal shock, etc., and achieve strong bonding, promotion of upgrades, and good compression resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

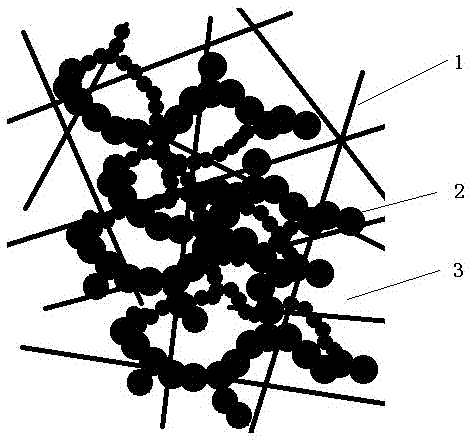

Image

Examples

Embodiment 1

[0039] According to the method of patent CN2014102703529, the quartz fiber felt reinforced silica airgel plate is prepared, the size of the silica airgel plate is 300mm*300mm*10mm, the density of the silica airgel is 110kg / m3, and the average pore diameter is 37nm , the porosity is 91%. Aluminum is used as the metal, and aluminum liquid is prepared by heating the metal aluminum to 780°C, and 1%wt metal chromium is added as a permeation aid solvent. The composite process adopts extrusion impregnation technology, pre-lays the glass fiber reinforced silica airgel plate in the closed cavity, locks the mold, injects aluminum liquid, slowly pressurizes to 85MPa, and the extrusion speed is 1cm / s , hold the pressure for 20 minutes, soak the reinforced material, cool and solidify, and then demould to form a composite material.

Embodiment 2

[0041] According to the method of patent CN2015102953891, the carbon fiber unidirectional cloth reinforced silica-titania airgel cloth is prepared, the size of the silica-titania airgel cloth is 300mm*300mm*2mm, and the density of the silica airgel is 80kg / m3, the average pore diameter is 45nm, and the porosity is 93%. The metal is aluminum alloy with the following composition: 10% Si, 0.5% Ca, and 6% Mg. After heating to 850°C to become aluminum alloy liquid, 3% nano-iron oxide is added as a penetration aid. The composite process adopts pressureless impregnation technology, fiber unidirectional cloth reinforced silica-titania airgel cloth is pre-laid in the closed mold cavity, argon gas is introduced as protective gas, aluminum alloy liquid is injected, and ultrasonic waves are introduced. After 10 minutes, the impregnation is completed, and the composite material is obtained after cooling.

Embodiment 3

[0043] According to the method of patent CN2015102953891, the tungsten wire reinforced zirconia airgel thin felt is prepared. The size of the tungsten wire reinforced zirconia airgel thin felt is 200mm*200mm*1mm, and the density of the zirconia airgel is 108kg / m3, the average The pore diameter is 32nm and the porosity is 90%. The metal adopts nickel alloy with the following composition, Ni is 32%, Cr is 21%, and the nickel alloy liquid is prepared in a furnace at 1480 °C. The composite process adopts vacuum impregnation technology. The tungsten wire reinforced zirconia airgel thin felt is pre-laid in the closed mold cavity, and the mold cavity is vacuumed to a degree of 20 torr. After the infiltration is completed, the composite material is obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com