Formwork support system for large-span overhanging structure and construction method of formwork support system

A large-span cantilever, structural formwork technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building structure, etc. , The construction deformation of the cast-in-place concrete structure is too large, and the construction of the cantilever beam and the cantilever plate is difficult to achieve, so as to achieve the effect of good bearing capacity, reliability, safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

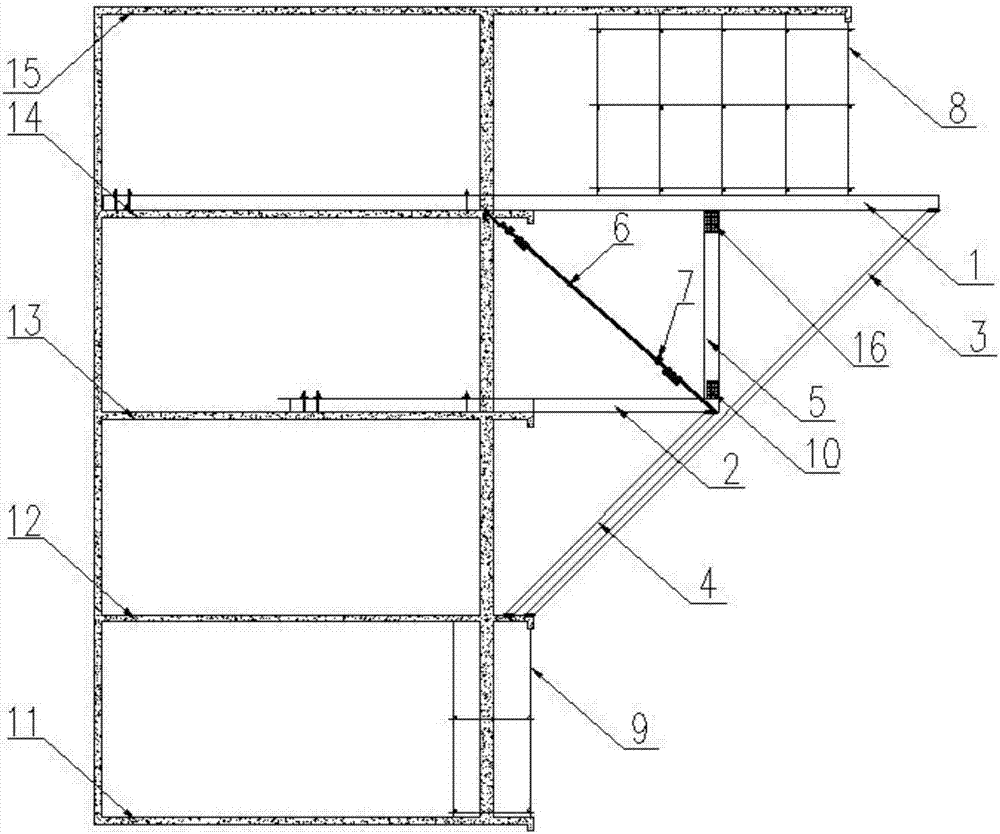

[0038] Such as figure 1 As shown, a formwork support system for a large-span cantilevered structure includes a floor beam slab and a scaffolding support 8, and the floor beam slab includes a first-story floor beam-slab 11, a second-floor floor beam-slab 12, and a third-floor floor beam slab 13, the fourth floor beam slab 14 and the fifth floor beam slab 15,

[0039] It includes an auxiliary support 9 arranged between the ends of the beam plate 11 of the first floor and the end of the beam plate 12 of the second floor;

[0040] The lower cantilevered I-beam 2 is fixed on the third floor beam plate 13, and the lower cantilevered I-beam 2 extends out of the third floor beam plate 13, and the end of the lower cantilevered I-beam 2 is connected to the A lower oblique support 4 is arranged between the beam slabs 12 of the second floor, and a cable-stayed steel wire rope 6 is arranged between the cantilevered I-beam 2 of the lower part and the beam slab 14 of the fourth floor;

[0...

Embodiment 2

[0047] Such as figure 1 As shown, a construction method of a formwork support system for a large-span cantilevered structure includes the following steps:

[0048] Step 1, setting up auxiliary support 9;

[0049] Step 2, the middle layer measuring and setting out sets the lower cantilevered I-beam 2 pre-embedded bolts;

[0050] Step 3, the upper floor measurement setting-out is provided with a pre-embedded U-shaped ring at the bottom of the beam plate 14 end of the fourth floor, and the upper cantilevered I-beam 1 pre-embedded bolt is set;

[0051] Step 4, set up the cantilevered I-beam 2 at the lower part, pull the steel wire rope 6, and weld the lower diagonal support 4; weld the steel bar in advance for fixing the contact part between the lower end of the steel wire rope 6 and the I-beam; weld the upper part of the channel steel first for the lower diagonal support 4 position, then weld the steel pressure plate at the lower part of the channel steel, and finally use chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com