Pressure filtration type hole sealing device for rapidly-hardened mine and using method thereof

A hole sealer, mining technology, applied in mining equipment, earthwork drilling, sealing/packing, etc., can solve the problems of atmospheric environment pollution, short drilling life, fast gas concentration decay, etc. Good performance, excellent blocking effect, rapid moisture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of use method of the pressure filter type quick-hardening mine sealing device of the present invention comprises the following steps:

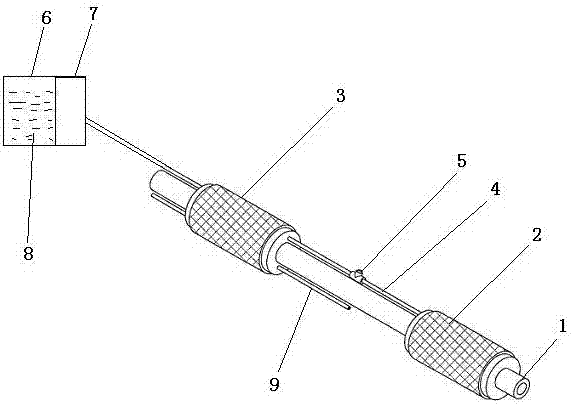

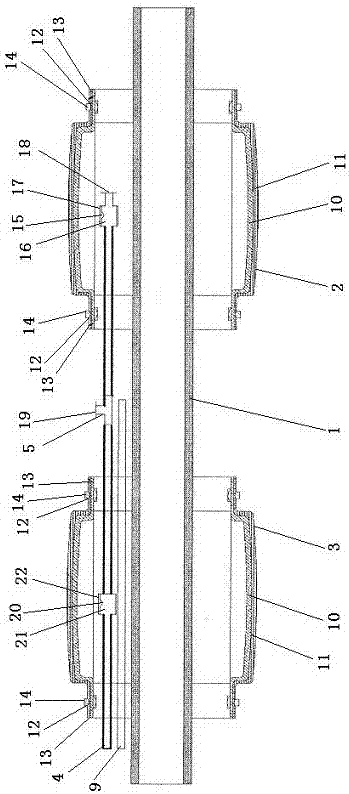

[0049] first step laying

[0050] Extend the gas drainage pipe body 1 into the borehole so that the front fiber capsule 2 and the rear fiber capsule 3 are in the borehole, the rear parts of the grouting pipe 4 and the overflow pipe 9 are outside the borehole, and the mine The high-pressure pipe of the pneumatic grouting pump 7 is connected with the rear portion of the grouting pipe 4;

[0051] The second step grouting

[0052] Put 50 parts by weight of water, 15 parts by weight of sulphoaluminate cement, 70 parts by weight of ordinary portland cement, 1 part by weight of aluminum sulfate, and 1 part by weight of calcium sulphoaluminate into the portable pneumatic Stirring barrel 6, use portable pneumatic mixing barrel 6 to stir special mine sealing material 8, and then use mine pneumatic grouting pump 7 to input mine sealing sp...

Embodiment 2

[0058] A kind of use method of the pressure filter type quick-hardening mine sealing device of the present invention comprises the following steps:

[0059] first step laying

[0060] Extend the gas drainage pipe body 1 into the borehole so that the front fiber capsule 2 and the rear fiber capsule 3 are in the borehole, the rear parts of the grouting pipe 4 and the overflow pipe 9 are outside the borehole, and the mine The high-pressure pipe of the pneumatic grouting pump 7 is connected with the rear portion of the grouting pipe 4;

[0061] The second step grouting

[0062] Put 60 parts by weight of water, 20 parts by weight of sulphoaluminate cement, 75 parts by weight of ordinary portland cement, 5.5 parts by weight of aluminum sulfate, and 2 parts by weight of calcium sulphoaluminate into the portable pneumatic Stirring barrel 6, use portable pneumatic mixing barrel 6 to stir special mine sealing material 8, and then use mine pneumatic grouting pump 7 to input mine sealin...

Embodiment 3

[0068] A kind of use method of the pressure filter type quick-hardening mine sealing device of the present invention comprises the following steps:

[0069] first step laying

[0070] Extend the gas drainage pipe body 1 into the borehole so that the front fiber capsule 2 and the rear fiber capsule 3 are in the borehole, the rear parts of the grouting pipe 4 and the overflow pipe 9 are outside the borehole, and the mine The high-pressure pipe of the pneumatic grouting pump 7 is connected with the rear portion of the grouting pipe 4;

[0071] The second step grouting

[0072] Put 70 parts by weight of water, 25 parts by weight of sulphoaluminate cement, 80 parts by weight of ordinary Portland cement, 10 parts by weight of aluminum sulfate, and 3 parts by weight of calcium sulphoaluminate, into a portable pneumatic Stirring barrel 6, use portable pneumatic mixing barrel 6 to stir special mine sealing material 8, and then use mine pneumatic grouting pump 7 to input mine sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com