Auxiliary-machine power system for double-machine backheating

A power system and plant power system technology, which is applied in the field of auxiliary power system for dual-machine reheating, can solve the problems of difficult control of water level, reduced efficiency, and great influence on energy consumption level and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

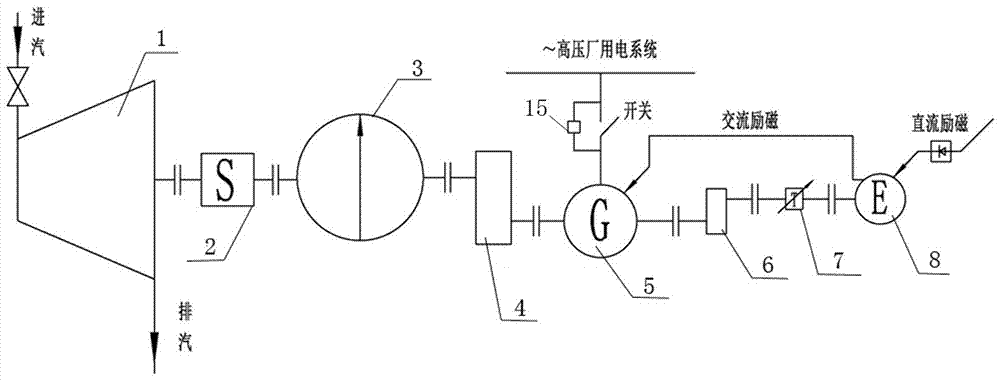

[0024] Embodiment 1: as figure 1 As shown, adopting the scheme design of the present invention, the specific parameters can be flexibly selected according to the engineering needs. For example, the design speed range of the required feedwater pump is 3000-6000rpm (corresponding to the AC excitation frequency range of 40-30hz, and the corresponding output speed range of the permanent magnet governor is 89.3%~33.5%), the gearbox A speed ratio is 5, the speed range of the main motor is 600~1200rpm, the number of pole pairs of the main motor is 1, the number of pole pairs of the exciter is 2, and the speed ratio of gearbox B is 2.293 Design, and other parameters can also be optimized according to the critical speed of the main motor and technical conditions such as carbon brush slip rings.

[0025] figure 1 Schematic speed-power decoupling control of small steam turbine-motor variable speed dual-drive feed pump system (exciter coaxial drive).

[0026] When starting the water pu...

Embodiment 2

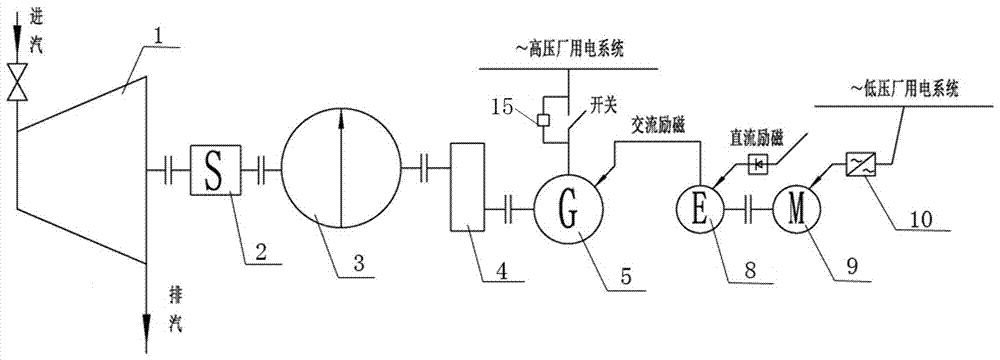

[0029] Embodiment 2: as figure 2 As shown, adopting the scheme design of the present invention, the specific parameters can be flexibly selected according to the needs of the project. For example, the design speed range of the required feedwater pump is 3000-6000rpm (corresponding to the AC excitation frequency range of 40-30hz, and the corresponding frequency converter adjustment range of 40.4-30.3hz , the excitation motor is an asynchronous motor, and its slip rate is calculated according to 1%), the gear box A speed ratio is 5, the speed range of the main motor is 600-1200rpm, the number of pole pairs of the main motor is 1, and the number of pole pairs of the exciter is 2. The number of magnetic pole pairs of the excitation motor is 2, and other parameters can also be optimized according to the critical speed of the main motor and technical conditions such as carbon brush slip rings.

[0030] In this embodiment, the permanent magnet governor arranged between the exciter a...

Embodiment 3

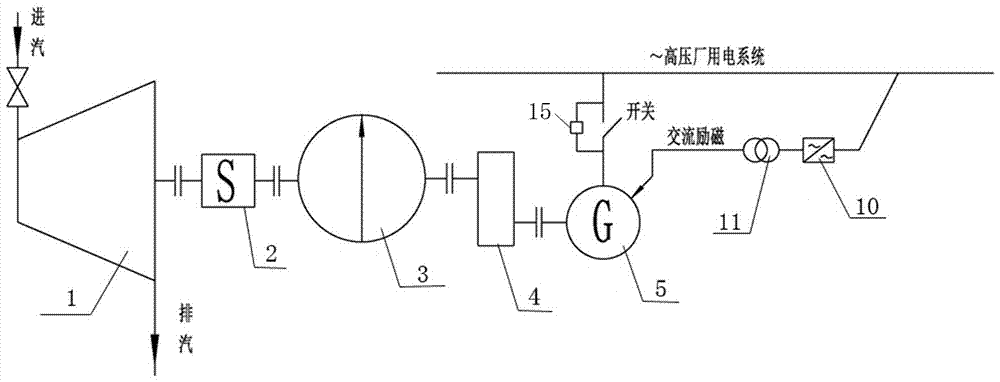

[0036] Embodiment 3: as image 3 As shown, with the scheme design of the present invention, the specific parameters can be flexibly selected according to the engineering needs. For example, the design speed range of the required feedwater pump is 3000-6000rpm (corresponding to the AC excitation frequency range of 40-30hz), and the gear box A speed ratio of 5 can be used. , The motor speed range is 600 ~ 1200rpm, the design of the motor pole pair is 1, and other parameters can also be optimized according to the critical speed of the motor and technical conditions such as carbon brush slip rings.

[0037] image 3 Schematic speed-power decoupling control of small steam turbine-motor variable speed dual-drive feed water pump system (excitation is provided by plant power frequency conversion).

[0038] When starting the water pump, you can choose to start the small machine first, or the main motor first.

[0039] When the small machine starts first, the small machine rushes forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com