Biomass boiler

A biomass boiler and furnace body technology, applied in the direction of combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of poor fluidity, unfavorable feeding, heat pollution of the surrounding environment, increased production costs, etc., to achieve good control, Low maintenance and operation cost, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

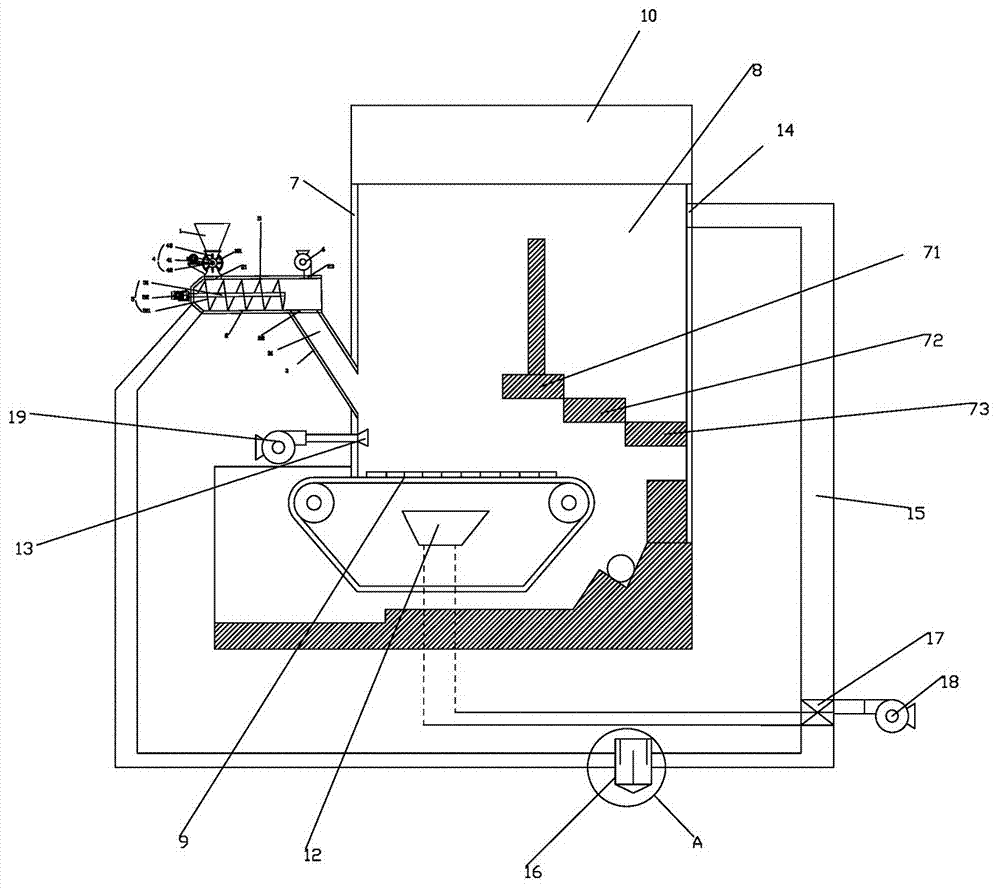

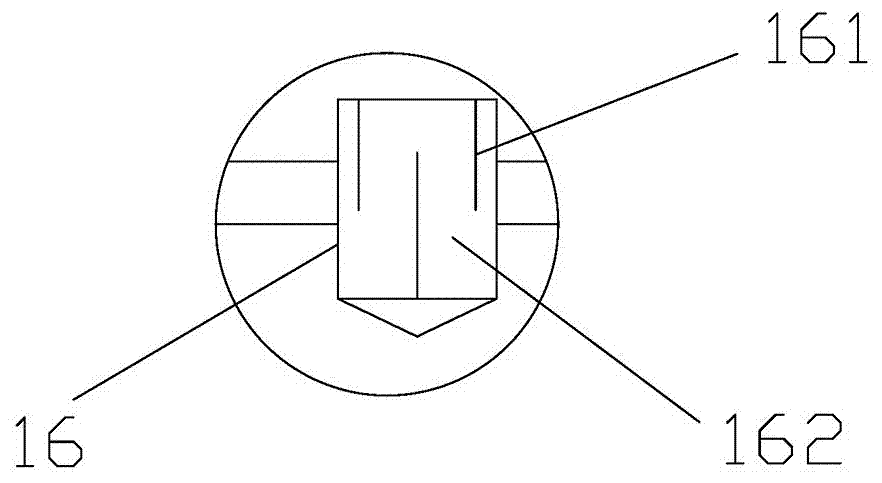

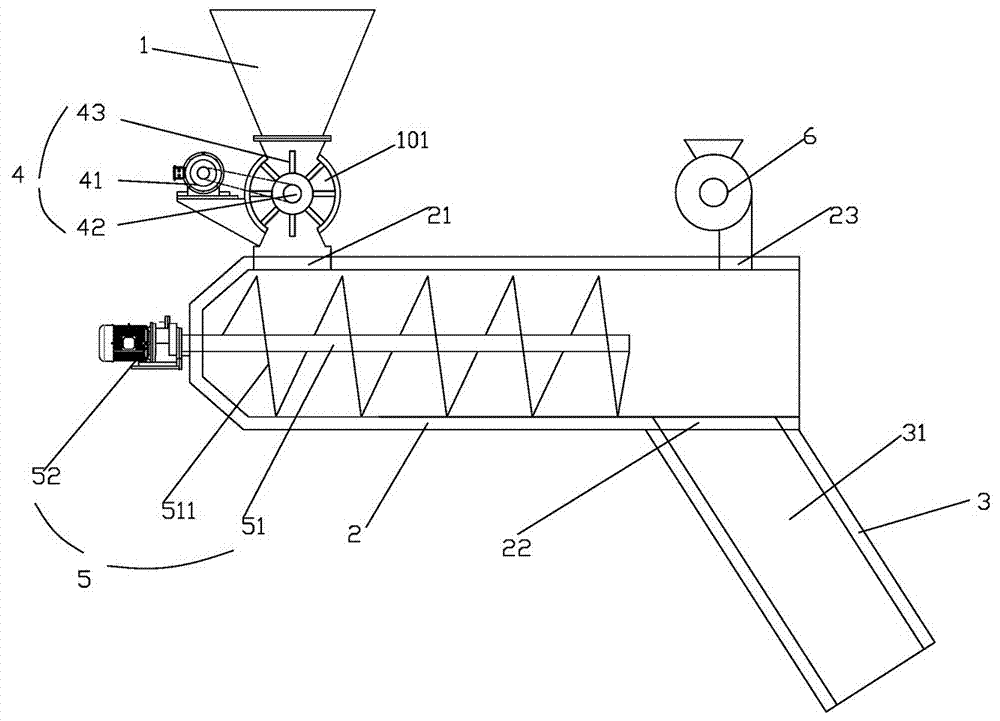

[0030] Example 1: Reference figure 1 , figure 2 as well as image 3 , a biomass boiler, comprising a furnace body 7, a combustion chamber 8 arranged inside the furnace body 7, a moving grate 9 arranged at the bottom of the combustion chamber 8, a feeding device 11 arranged at the moving grate 9, a The drum 10 above the chamber 8, the first air inlet chamber 12 arranged below the moving grate 9, the second air inlet chamber 13 arranged between the discharge port of the feeding device 11 and the moving fire grate, and the second air inlet chamber 13 arranged in the combustion chamber The smoke outlet 14 on the chamber 8, the smoke outlet 14 is connected with a flue gas pipe 15, the other end of the flue gas pipe 15 is connected to the inlet of the dust collector 16, and the outlet of the dust collector 16 is connected to the feeding device 11 through a pipeline To dry the material, the flue gas pipeline 15 is provided with an air preheater 17 that uses the flue gas in the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com