Method of utilizing soybean aqueous enzymatic method hydrolysate and residue to prepare Qianye tofu

A technology of thousand-sheet tofu and hydrolyzate, which is applied in the field of preparing thousand-sheet tofu, can solve the problems of easy loss of nutrients and moisture, and achieve the effects of shortening freezing time, improving elasticity and water absorption, and reducing the growth of microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

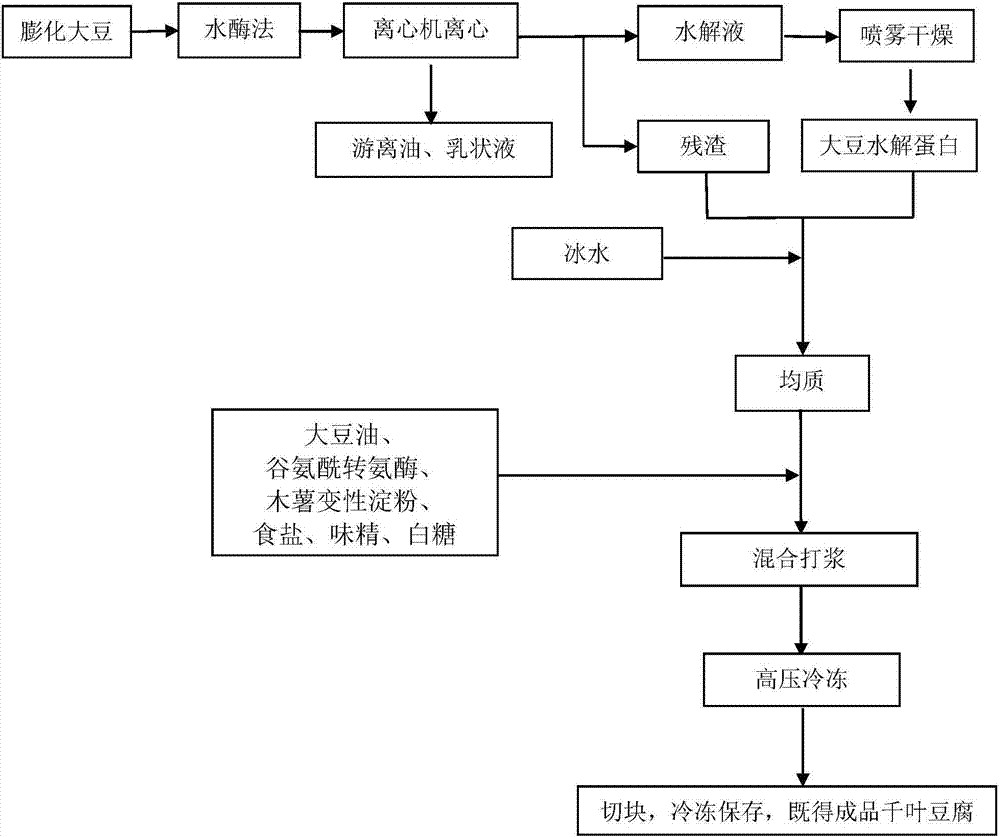

Image

Examples

Embodiment 1

[0023] The cleaned and pulverized soybeans are extruded and extruded for pretreatment, and the extruded extruded product is mixed with water at a volume ratio of 1:6 to obtain a mixed solution. Under the condition that Ph is 9, alkaline protease Protex 6L is added thereto, Keeping the Ph value constant, under stirring in a water bath at 55°C, perform enzymolysis for 3 hours to obtain an enzymolysis solution, centrifuge the enzymolysis solution to obtain free oil, emulsion, hydrolyzate and residue, collect the hydrolyzate, and keep the inlet temperature at 160°C , spray drying at an outlet temperature of 67°C to obtain aqueous enzymatic soybean protein. Homogenize 67 to 70 parts by weight of ice water, 14 to 17 parts by weight of soybean protein by water enzymatic method, and 6 to 8 parts by weight of residue of water enzymatic method for 10 minutes, add 2 to 3 parts by weight of soybean oil, 0.12 to 0.21 parts by weight of grain aminoacyltransaminase, 4-7 parts by weight of ca...

Embodiment 2

[0025] The cleaned and pulverized soybeans are extruded and extruded for pretreatment, and the extruded extruded product is mixed with water at a volume ratio of 1:6 to obtain a mixed solution. Under the condition that Ph is 9, alkaline protease Protex 6L is added thereto, Keeping the Ph value constant, under stirring in a water bath at 55°C, perform enzymolysis for 3 hours to obtain an enzymolysis solution, centrifuge the enzymolysis solution to obtain free oil, emulsion, hydrolyzate and residue, collect the hydrolyzate, and keep the inlet temperature at 160°C , spray drying at an outlet temperature of 67°C to obtain aqueous enzymatic soybean protein. Homogenize 67 to 70 parts by weight of ice water, 14 to 17 parts by weight of soybean protein by water enzymatic method, and 6 to 8 parts by weight of residue of water enzymatic method for 10 minutes, add 2 to 3 parts by weight of soybean oil, 0.12 to 0.21 parts by weight of grain aminoacyltransaminase, 4-7 parts by weight of ca...

Embodiment 3

[0027] The cleaned and pulverized soybeans are extruded and extruded for pretreatment, and the extruded extruded product is mixed with water at a volume ratio of 1:6 to obtain a mixed solution. Under the condition that Ph is 9, alkaline protease Protex 6L is added thereto, Keeping the Ph value constant, under stirring in a water bath at 55°C, perform enzymolysis for 3 hours to obtain an enzymolysis solution, centrifuge the enzymolysis solution to obtain free oil, emulsion, hydrolyzate and residue, collect the hydrolyzate, and keep the inlet temperature at 160°C , spray drying at an outlet temperature of 67°C to obtain aqueous enzymatic soybean protein. Homogenize 67 to 70 parts by weight of ice water, 14 to 17 parts by weight of soybean protein by water enzymatic method, and 6 to 8 parts by weight of residue of water enzymatic method for 10 minutes, add 2 to 3 parts by weight of soybean oil, 0.12 to 0.21 parts by weight of grain aminoacyltransaminase, 4-7 parts by weight of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com