Underground coal separation method and system

A production method and production system technology, applied in the direction of solid separation, etc., to achieve the effects of saving floor space, wide application range, and reducing stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

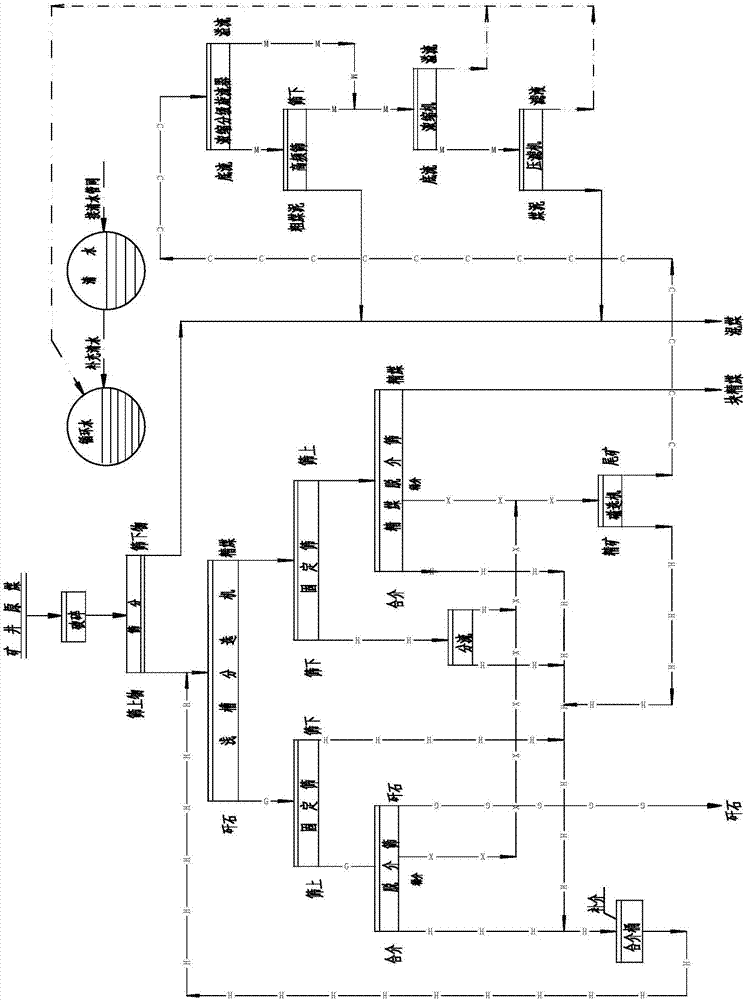

[0028] The underground coal preparation method of the present invention is as follows: a coal preparation plant is built under the mine, and after washing, various product coals are transported to the ground product warehouse through a lifting system or a belt conveyor, and the gangue after washing is directly used for underground filling Goaf.

[0029] In the method of the present invention, the coal preparation process adopts lump coal dense-medium shallow tank separation, the fine coal is not washed, the coarse coal slime is recovered by a concentrated and graded cyclone and a high-frequency screen, and the fine coal slime is recovered by a filter press; The coal preparation plant realizes the closed loop of washing water.

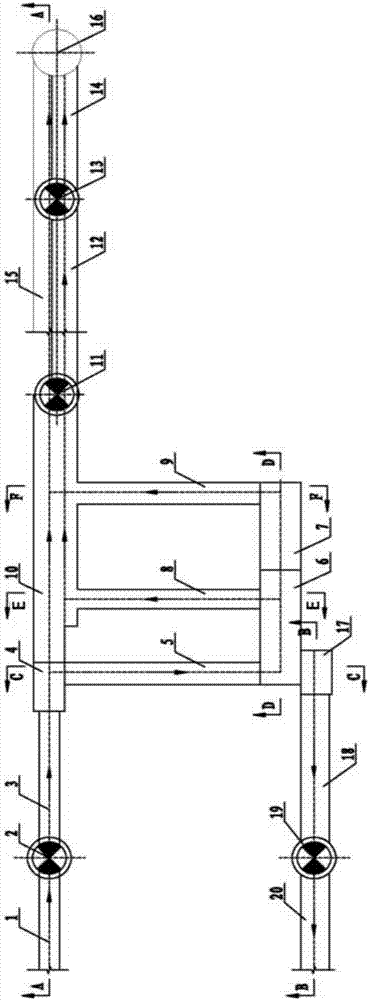

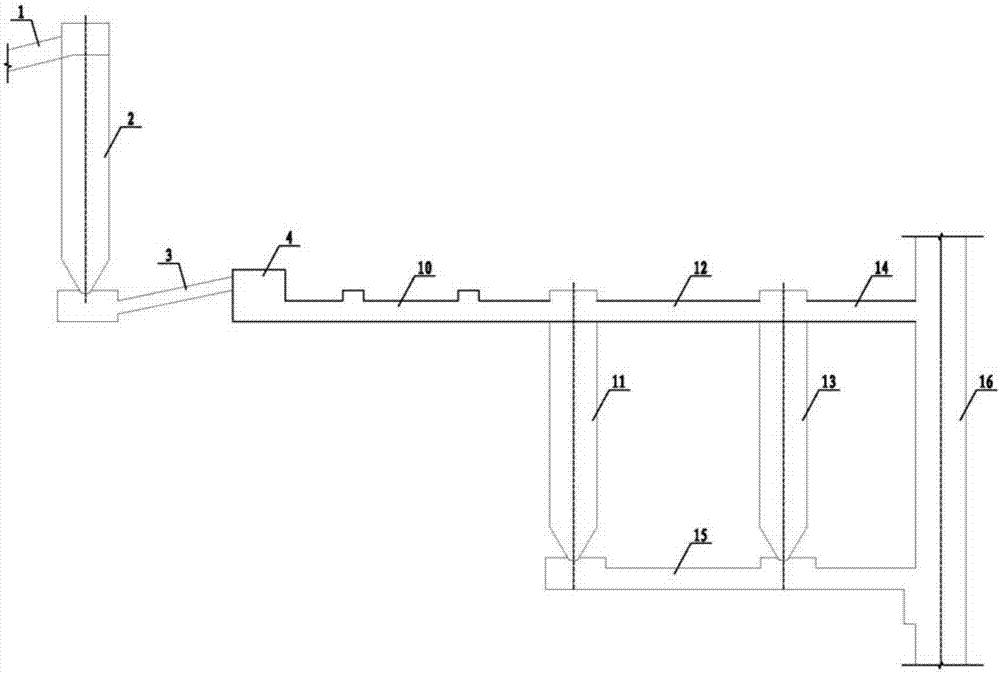

[0030] Figure 1-8 It is the embodiment that realizes above method, below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0031] The production system of the underground coal preparation plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com