Thermal sublimation ink based on disperse black dye compounding, and preparation method thereof

A thermal sublimation and disperse black technology, applied in dyeing, ink, pigment slurry, etc., can solve the problems of unusable application, easy wrinkling of printing paper, etc., and achieve the effect of strong coloring, high transfer rate and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

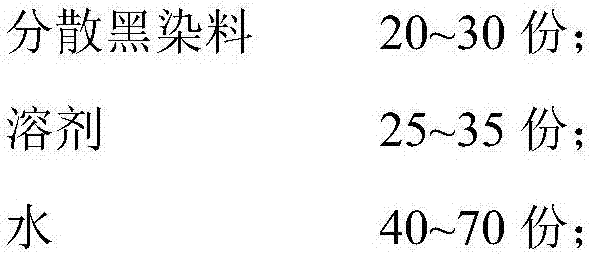

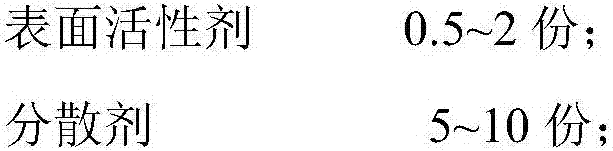

[0025] Another object of the present invention is to provide a kind of preparation method based on the thermal sublimation ink of compound disperse black dye, it comprises the following steps: (a) add the water of formula quantity, dispersant, solvent and surfactant to container successively agent, carry out shear dispersion; then continue to add the dyestuff of formula quantity in described container, carry out stirring dispersion; (b) use the zirconia beads of different particle diameters to grind the product of step (a), the zirconia beads The particle size is changed from large to small; (c) add water of the same quality to the product of step (b), then centrifuge to remove the large particle residue, filter to obtain the color paste; (d) mix the color paste with wetting Agent, leveling agent, solvent and water can be prepared in proportion to make sublimation ink.

[0026] In the step (b), zirconia beads of 0.6-0.8 mm, 0.25-0.35 mm and 0.1-0.2 mm are used for grinding in ...

Embodiment 1-12、 comparative example 1-3

[0029] Embodiments 1-12 and Comparative Examples 1-3 respectively provide a sublimation ink based on a compounded disperse black dye. In order to compare the influence of the color paste on its performance during preparation, the following fixed mass ratios are used for preparation, specifically: Color paste 20%, wetting agent 5% (TOGO260), leveling agent 5% (DC-401LS), water 50% and solvent 20%, that is, color paste 200g, TOGO26050g, DC-401LS 50g, water 500g and solvent 200g (the solvents used before and after remain consistent); and the composition of the color paste is as shown in table 1; its specific preparation method can be conventional, and can refer to the Chinese invention patent that the patent number is 201310270976.6, specifically: (1) room temperature ( At 20°C), mix the disperse dye and dispersant according to the formula ratio, use zirconium beads with a diameter of 0.25-0.35mm in a sand mill at a speed of 2200-2800r / min, and grind and disperse for 24 hours to o...

Embodiment 13

[0038] The present embodiment provides a kind of preparation method that is used for the preparation of the high stability color paste of sublimation ink, and it comprises the following steps:

[0039] (a) Add water, dispersant, solvent and surfactant to the container successively according to the component content in Example 12, and carry out shear dispersion; then continue to add dyes to the container, and stir to make it evenly dispersed;

[0040] (b) successively use zirconia beads of 0.6-0.8mm, 0.25-0.35mm and 0.1-0.2mm to grind the products of step (a) for 0.5-5 hours respectively, so that the particle diameter of the dye particles is D90≤200nm, D80≤ 150nm and D75≤100nm;

[0041] (c) in the product of step (b) (the dyestuff solid content of product is about 20%), add the water of its same quality, centrifuge then and remove large particle residue, use three grades of in-line filters to filter, filter to obtain color paste ( Solid content is reduced to about 10%); Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com