Multi-chamber rotational-flow stepped high-efficiency heat exchanging system of rotary pyrolyzing furnace

A technology of heat exchange system and pyrolysis furnace, which is applied in the field of multi-chamber swirl cascade high-efficiency heat exchange system of rotary pyrolysis furnace, can solve the problems of uneven heat exchange, low energy utilization rate, insufficient and stable heating, etc. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

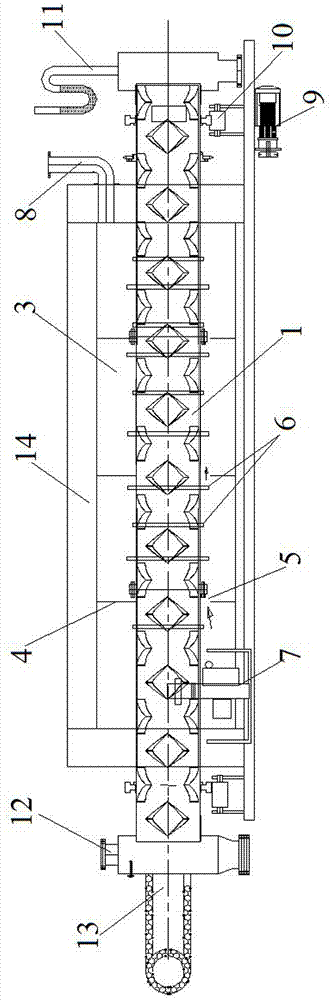

[0022] For the convenience of explanation, the invention's multi-chamber swirl cascade high-efficiency heat exchange system for rotary pyrolysis furnace will be described in detail below in conjunction with the accompanying drawings.

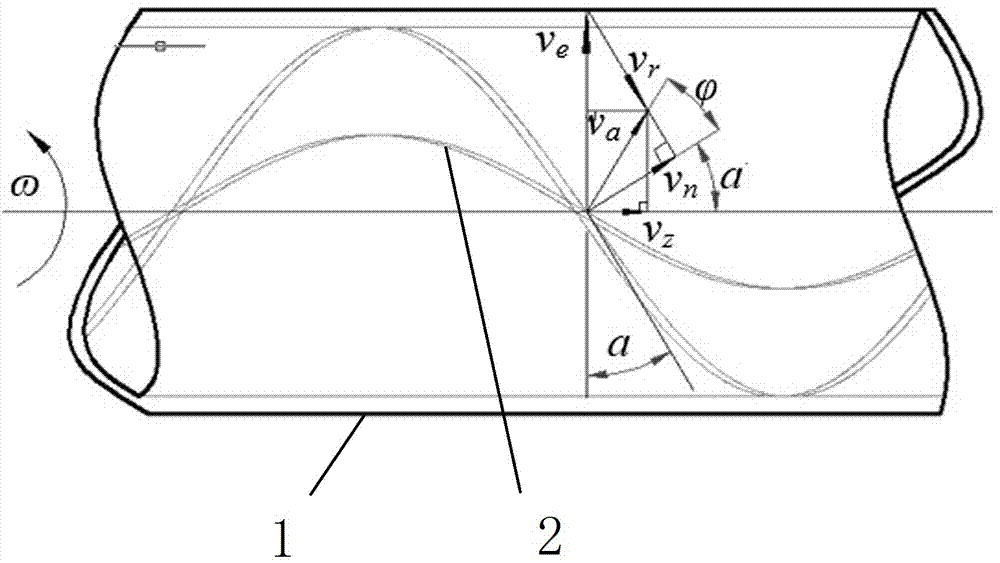

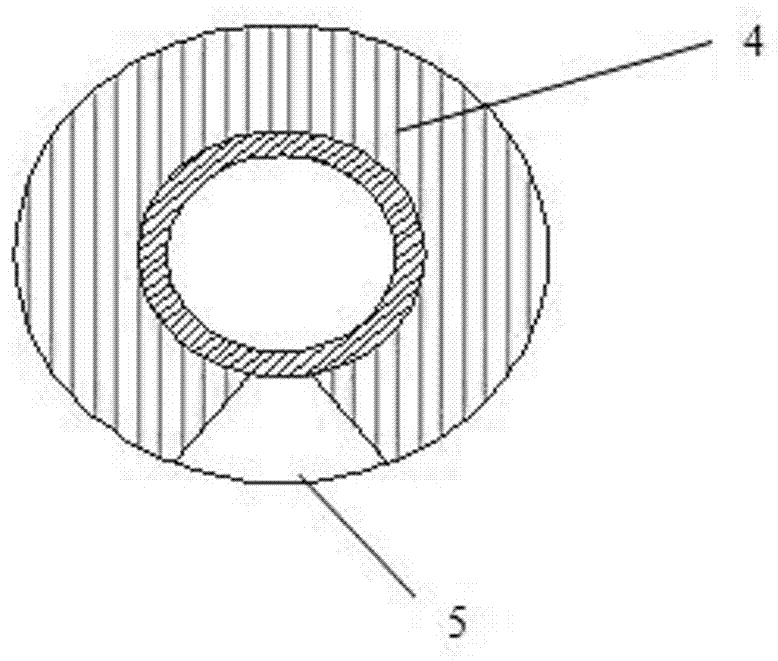

[0023] Such as Figure 1 to Figure 4 As shown in , a rotary pyrolysis furnace multi-chamber swirling cascade high-efficiency heat exchange system includes a heating chamber, the heating chamber 3 is divided into no less than two heating chambers through a partition 4, and two adjacent The bottom of each heating chamber is provided with a hot gas outlet 5 that communicates with the two heating chambers. The heating chamber 3 is provided with several annular fins 6; the fins 6 have the same or different dimensions, and two adjacent The size of the fins 6 is different; the fins 6 are annularly arranged on the periphery of the multi-line spiral flight conveyor mechanism, and rotate together with the cylinder body. The first heating chamber 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com