Miniaturized CTS flat panel array antenna

An array antenna and flat panel technology, applied in antennas, antenna arrays, linear waveguide feed arrays, etc., can solve problems such as high assembly requirements, high processing requirements for offset parabolic reflectors, and large size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

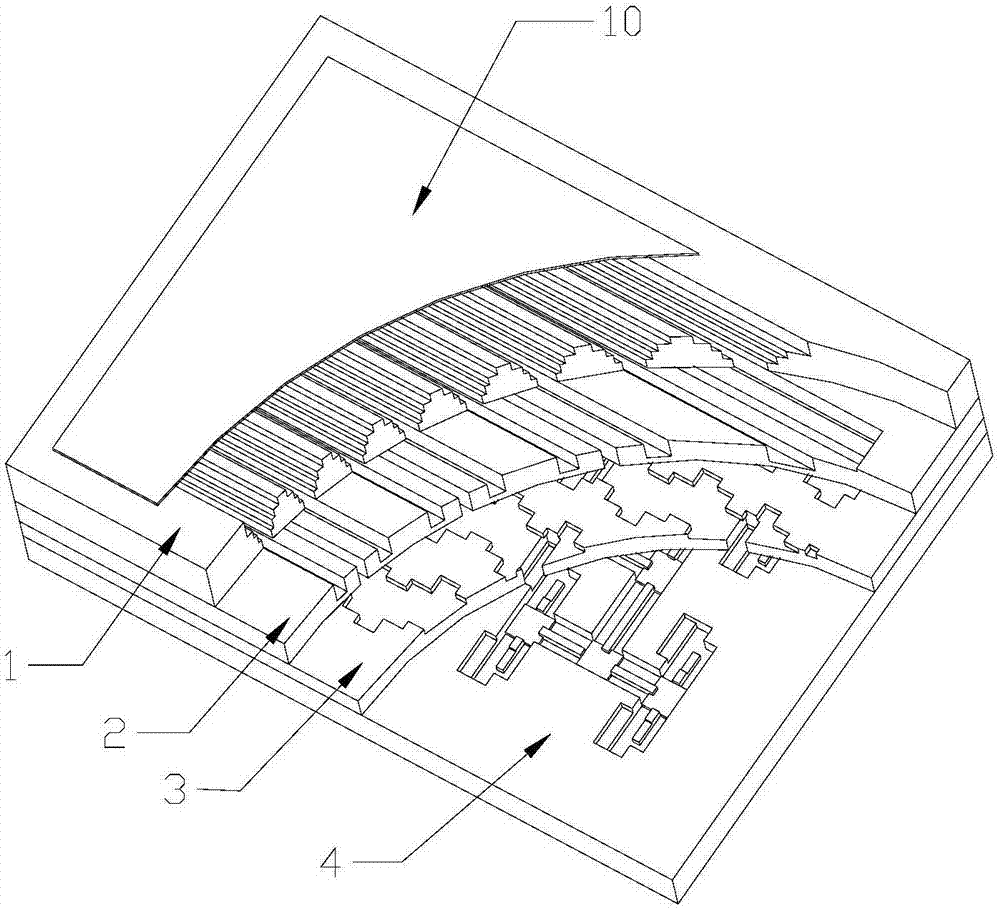

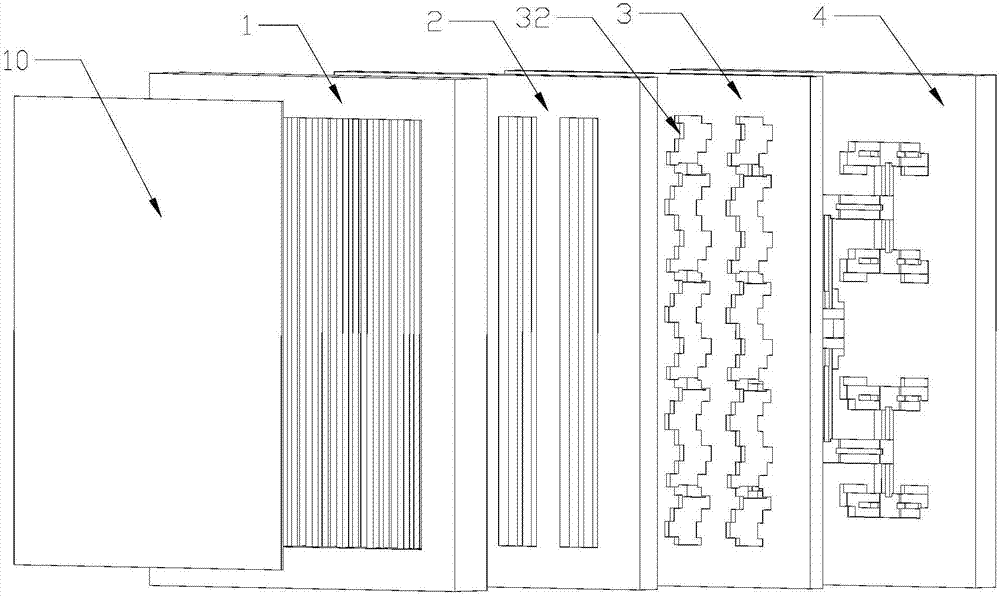

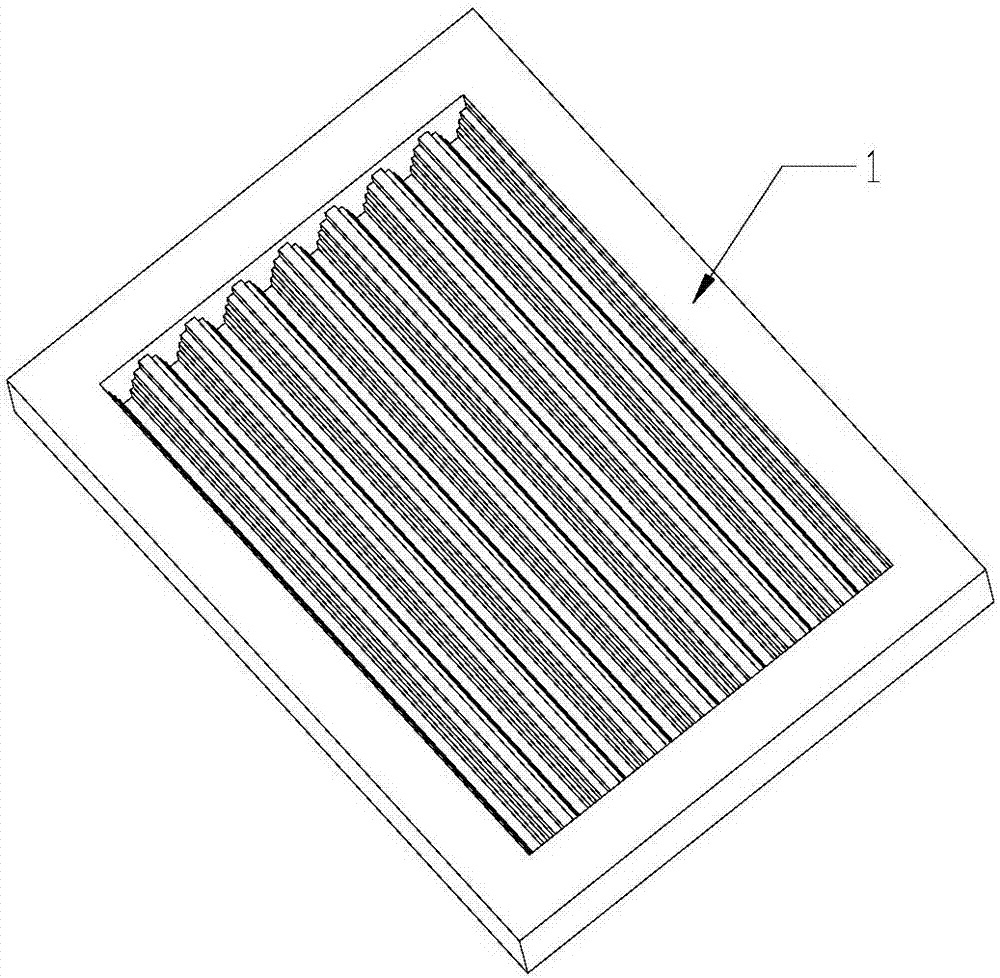

[0026] Embodiment one: if Figure 1-Figure 6 As shown, a miniaturized CTS panel array antenna includes a radiation layer 1, a waveguide work layer 2, a mode conversion layer 3 and a feed network layer 4 arranged in sequence from top to bottom; the mode conversion layer 3 includes a first metal plate 31 and the mode conversion cavity array 32 arranged on the upper surface of the first metal plate 31, the mode conversion cavity array 32 consists of n 2 The mode conversion cavities 33 are arranged in the form of n rows×n columns, n is an integer greater than or equal to 4, and the n mode conversion cavities 33 located in the same column are connected end to end in turn, and the mode conversion cavities 33 located in the kth row and the jth column The center distance between the mode conversion cavity 33 located in row k and column j+1 is between 1.5 times the wavelength and 2 times the wavelength, k=1, 2, 3, ..., n, j=1, 2 , 3, ..., n-1, the mode conversion cavity 33 includes a ...

Embodiment 2

[0029] Embodiment two: if Figure 1-Figure 6 As shown, a miniaturized CTS panel array antenna includes a radiation layer 1, a waveguide work layer 2, a mode conversion layer 3 and a feed network layer 4 arranged in sequence from top to bottom; the mode conversion layer 3 includes a first metal plate 31 and the mode conversion cavity array 32 arranged on the upper surface of the first metal plate 31, the mode conversion cavity array 32 consists of n 2 The mode conversion cavities 33 are arranged in the form of n rows×n columns, n is an integer greater than or equal to 4, and the n mode conversion cavities 33 located in the same column are connected end to end in turn, and the mode conversion cavities 33 located in the kth row and the jth column The center distance between the mode conversion cavity 33 located in row k and column j+1 is between 1.5 times the wavelength and 2 times the wavelength, k=1, 2, 3, ..., n, j=1, 2 , 3, ..., n-1, the mode conversion cavity 33 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com