High-gelling plasma protein powder and preparation method thereof

A technology of plasma protein powder and high gel, which is applied in the direction of blood protein components, animal protein processing, protein food components, etc., can solve problems such as conformational changes, affecting plasma protein functions, protein denaturation, etc., and achieve hardness improvement and solubility Good, low degree of protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

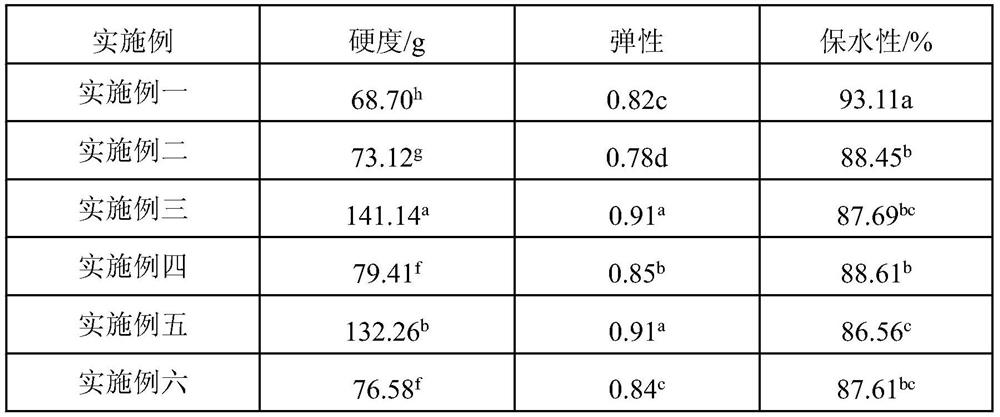

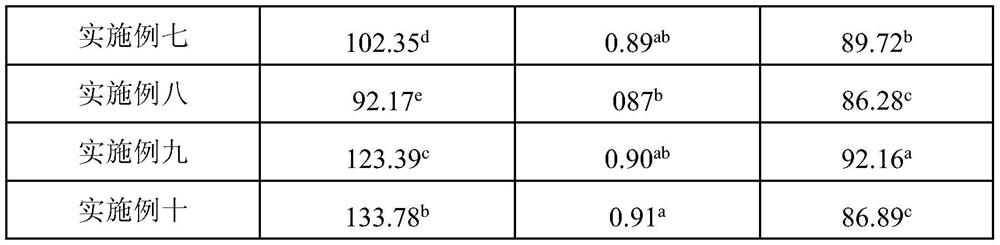

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of high-gelling plasma protein powder, comprising:

[0025] Step (1) blood collection: collect fresh healthy animal blood, add anticoagulant, mix well, and the animal blood is livestock blood;

[0026] Step (2) Static separation: the anticoagulated blood is allowed to stand at 4°C-8°C for 3-8 hours;

[0027] Step (3) equipment separation: centrifuge the rested blood supernatant at 4°C to 6°C to obtain plasma;

[0028] Step (4) Membrane Concentration: Concentrate and desalinize the plasma liquid by ultrafiltration, then use nanofiltration to concentrate the ultrafiltration permeate, and mix the ultrafiltration concentrate and nanofiltration concentrate in proportion Mixing, the ratio is 1 to 7:1, and the specific process parameters of the ultrafiltration method are: the ultrafiltration membrane molecular weight cut-off is 5000 to 10000Da, the ultrafiltration temperature is 16°C to 25°C, and the pH of the feed l...

Embodiment 1

[0046] (1) Blood collection: fresh healthy animal blood was collected with a vacuum blood collection knife, added with an anticoagulant to make the final concentration 0.345%, mixed evenly, and stored under refrigerated conditions. (2) Static separation: the blood was allowed to stand at 6°C for 6 hours, and the supernatant liquid was centrifuged at 2437×g for 10 minutes to obtain plasma. (3) Regulate the pH of the plasma liquid to be 9.0, 0.6MPa ultrafiltration to the end, the permeate is subjected to nanofiltration, the nanofiltration pressure is 0.12MPa, and the mixing ratio of the ultrafiltration concentrate and the nanofiltration concentrate is 7:1 (v / v ). (3) Drying: The mixed plasma was pre-frozen at -30°C for 12 hours, and freeze-dried at -50°C for 72 hours in a cold trap. The resulting protein powder was adjusted to a protein solution concentration of 60 mg / mL, a pH of 9.0, and placed in a water bath at 85° C. for 45 minutes.

Embodiment 2

[0048] (1) Blood collection: fresh healthy animal blood was collected with a vacuum blood collection knife, added with an anticoagulant to make the final concentration 0.345%, mixed evenly, and stored under refrigerated conditions. (2) Static separation: the blood was allowed to stand at 6°C for 6 hours, and the supernatant liquid was centrifuged at 2437×g for 10 minutes to obtain plasma. (3) Regulating the pH of plasma liquid to be 9.0, 0.6MPa ultrafiltration to the end, the permeate is subjected to nanofiltration, the nanofiltration pressure is 0.12MPa, and the mixing ratio of ultrafiltration concentrate and nanofiltration concentrate is 5:1 (v / v ). (3) Drying: The mixed plasma was pre-frozen at -30°C for 12 hours, and freeze-dried at -50°C for 72 hours in a cold trap. The resulting protein powder was adjusted to a protein solution concentration of 60 mg / mL, a pH of 9.0, and placed in a water bath at 85° C. for 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com