Microemulsion mist spray and preparation method thereof

A technology of microemulsion and emulsifier, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problem of high instability and achieve the effect of increasing the effect of locking water and moisturizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

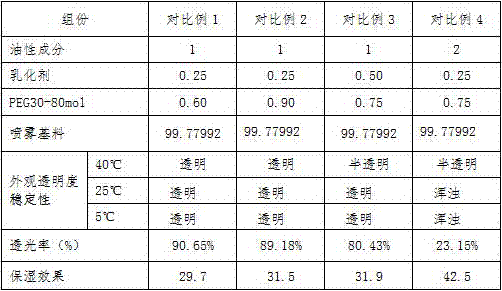

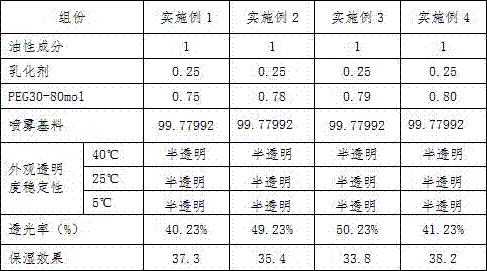

Embodiment 1-4 and comparative example 1-5

[0057] Embodiment 1-4 and comparative example 1-5: the preparation of microemulsion spray

[0058] First, add a part of the microemulsion spray base (88.2475g of water, 4.0g of glycerin, 1.50g of betaine, 3.00g of 1,3-propanediol, and 0.0002g of allantoin) into the water phase pot, heat to 70-75°C, and stir Evenly, pump into the vacuum emulsifier; then add oily ingredients, emulsifier, PEG 30-80mol non-ionic active agent according to the ratio in Table 1, add the oil phase pot, heat to 60-65°C, stir evenly, and pump into the vacuum In the emulsifier; then turn on the vacuum emulsifier, stir at a speed of 1000 rpm / min for 30 minutes, stop stirring, and cool down to 40°C; add the remaining microemulsion spray base (0.05g of purslane extract, β-glucose Polysaccharide 0.5g, hydrolyzed royal jelly protein 0.1g, menthol lactate 0.0001g, sugar isomers 0.05g, niacinamide 2.0g, PCA cocoyl arginine ethyl ester salt 0.07g, caprylyl hydroxy Xamic acid 0.25g, malachite extract 0.0001g, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com